Sanding sleeves, Notice, Lubrication – Woodstock SHOP FOX W1686 User Manual

Page 27

MAINTENANCE

-25-

Sanding Sleeves

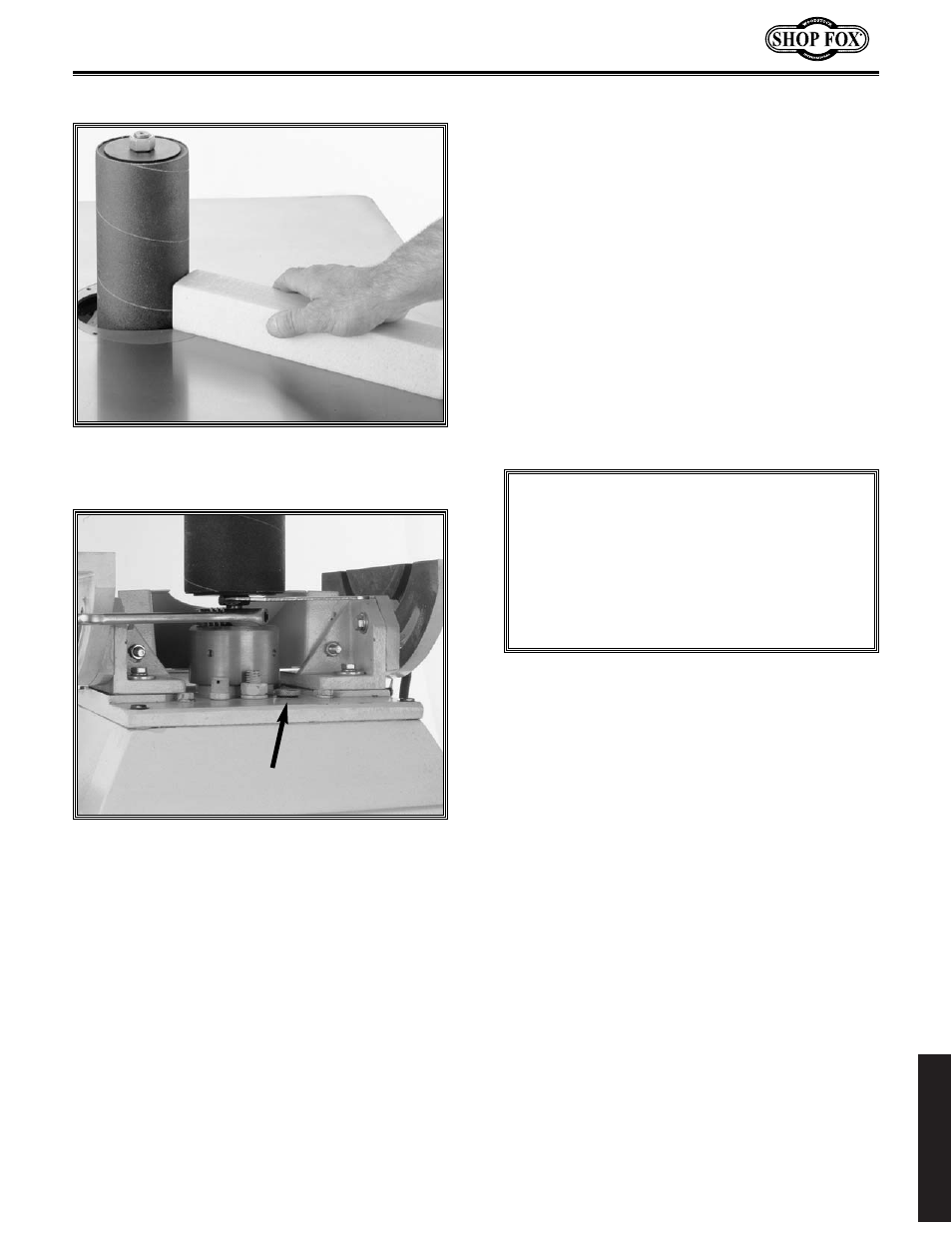

As sanding sleeves are used, they will quickly

become "loaded" with saw dust. If not removed,

this saw dust will harden on the abrasive sur-

face, rendering the sleeve useless. Routinely

clean the sanding sleeves with a rubber gum

abrasive cleaner (Figure 21) such as the PRO-

STIK

®

cleaners available from your local

Woodstock International dealer.

Always discard worn sanding sleeves. As abra-

sives begin to wear, grit will begin to fall off,

causing deep gouges in the workpiece. Glue

used to hold the grit to the paper will rub off

onto the workpiece causing burns and interfer-

ence with the final finishing.

NOTICE

Contrary to some beliefs, worn abrasives are

not equivalent to the next finer grit abrasive.

Discard worn sanding sleeves and avoid the

temptation to sand with them beyond their

usable life.

Lubrication

The spindle gear box contains 2.8 Qts. of 90 Wt.

gear oil. Replace the gear oil after approxi-

mately 1000 hours of use. Drain the gear oil from

the drain plug located inside the sander base at

the bottom of the gear box. The fill cap is shown

in Figure 21.

Since all bearings are shielded and permanently

lubricated, simply leave them alone until they

need to be replaced. Do not lubricate them, as

this will only attract dust and possible prema-

ture bearing failure.

DO NOT oil any exposed areas on the sander.

Dust will be attracted to these areas, creating a

gummy mixture that will hamper proper move-

ment of components. Instead, lubricate exposed

areas with dry powdered graphite.

Figure 21. Routinely clean sanding sleeves with

a rubber abrasive cleaning stick.

Figure 21. Routinely clean sanding sleeves with

a rubber abrasive cleaning stick.