Face plate turning, Operations – Woodstock SHOP FOX W1704 User Manual

Page 22

OPERATIONS

-20-

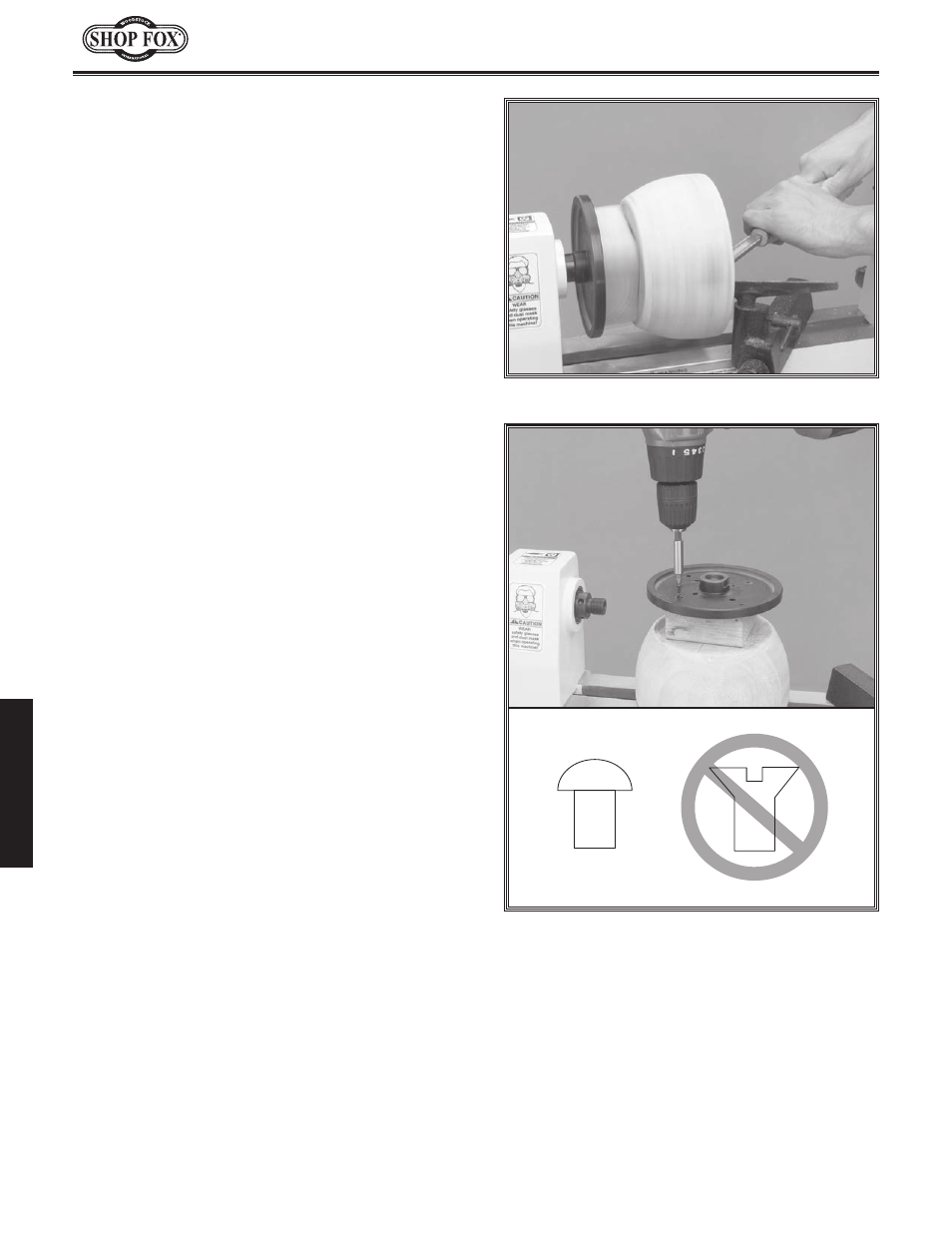

Figure 26. Typical face plate turning operation.

Face Plate turning (

Figure 26) is when a

workpiece is mounted to the face plate, which

is mounted to the headstock spindle.

To mount your workpiece to the face plate, do

these steps:

1. Find the center of your workpiece by draw-

ing diagonal lines from corner to corner

on the side of the workpiece that will be

mounted to the face plate. The intersection

point of these lines will show you the center

of your workpiece.

2. Cut off the corners of the workpiece if it is

thicker than 2" x 2".

3. Center the face plate on the workpiece and

attach it through the face plate holes with

wood screws, as shown in

Figure 27.

NOTICE: Only use tap screws or wood

screws with non-tapered heads (Figure 27)

to attach the face plate to the workpiece.

Do NOT use drywall screws or screws with

tapered heads because these can split the

face plate, or the screws may snap off

during operation.

4. Thread the face plate onto the headstock

spindle and tighten securely.

Note: If screws cannot be placed in the

workpiece, then a backing block can be

glued to the workpiece then attached to

the face plate with screws.

To mount your workpiece to a backing block,

do these steps:

1. Make the backing block from a piece of

scrap wood that is flat on both sides.

Face Plate Turning

Figure 27. Mounting face plate to a backing

block, which is glued to the workpiece.

2. Locate and mark the center of both the workpiece and the backing block.

3. Drill a

1

⁄

4

" hole in the center of the backing block.

4. Glue the center of the backing block to the center of the workpiece (look through the drilled hole to

line up centers), clamp the backing block to the workpiece, and wait for the glue to cure according

to the manufacturer’s recommendation.