Operation tips, Operations – Woodstock SHOP FOX W1704 User Manual

Page 19

OPERATIONS

-17-

• Mount the workpiece correctly; otherwise,

the operation may be difficult and danger-

ous. Read the “Spindle Turning” & “Face

Plate Turning” instructions for ideas on how

to set up your lathe correctly.

• Position the tool rest approximately

1

⁄

8

"

above the center line of the workpiece and

approximately

1

⁄

4

" away from the workpiece.

See

Figure 15 for more details.

• When turning the lathe ON, stand to the

side of the spinning direction until the lathe

reaches full speed and you can verify that

the lathe will not throw the workpiece.

• Always start the lathe and perform all rough

cutting with the speed setting at the lowest

point, as shown in

Figure 16.

• Select the right speed for the size of

workpiece you are turning. Use the slower

range on the speed dial for large workpieces

(4" diameter and over); use the middle

range on the speed dial for medium sized

workpieces (2" to 4" diameter); and use

the faster range on the speed dial for small

sized workpieces (under 2" in diameter).

• Keep the turning tool on the tool rest the

ENTIRE time that it is in contact with the

workpiece.

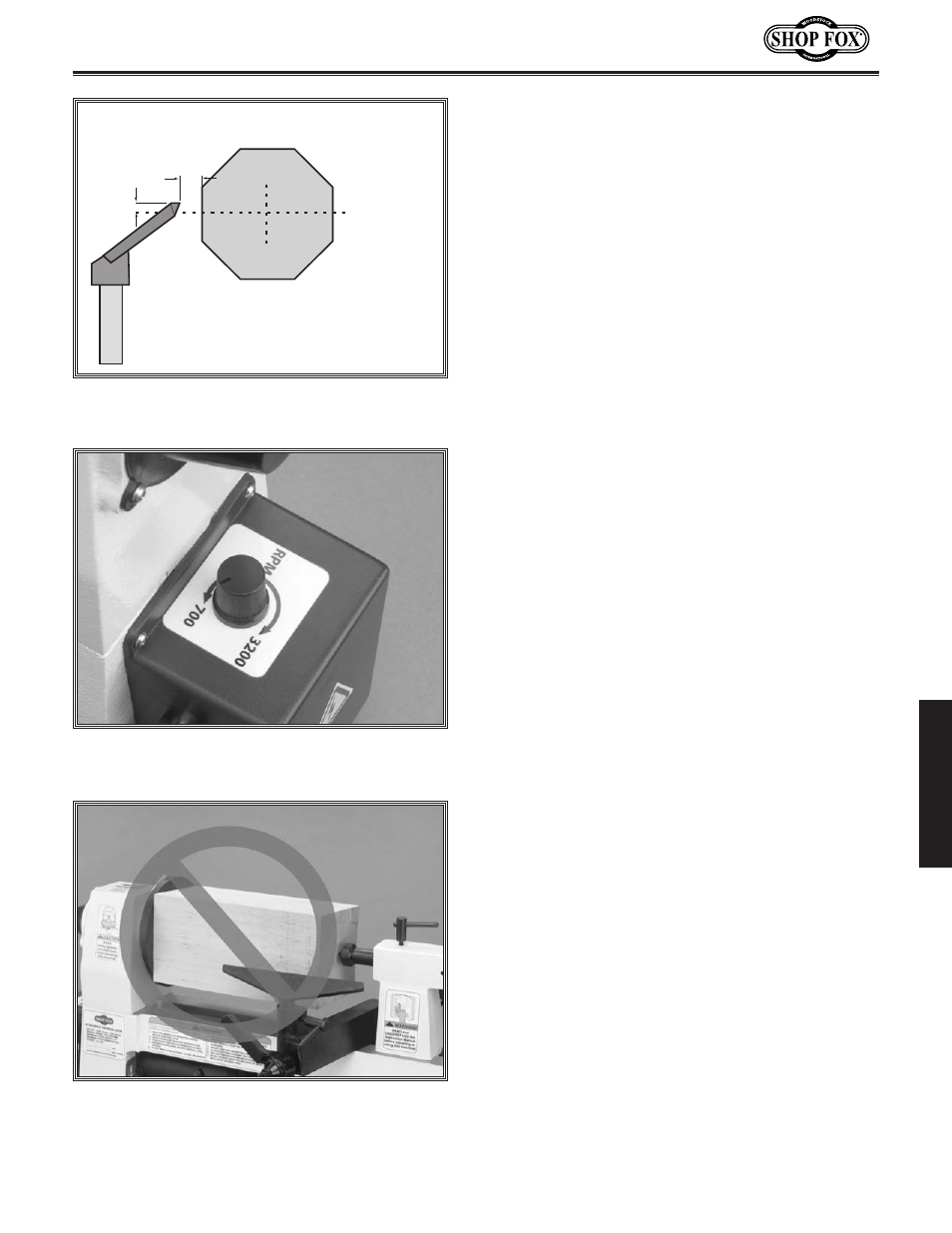

• When turning pieces thicker than 2" x 2", cut

off the corners first (so the workpiece profile

looks similar to the illustrated workpiece in

Figure 15). Figure 17 shows a workpiece

too big for turning with the corners still

on.

• When rough cutting face plate work, use

the live center in the tailstock for support,

as can be seen in the setup in

Figure 17.

After the rough cutting is complete, move

the tailstock out of the way.

• Learn the correct techniques for each tool

you will use. If you are unsure, read books

or magazines about lathe techniques and

seek training from experienced users.

Operation Tips

Figure 17. DO NOT attempt to turn workpieces

thicker than 2" x 2" without first cutting the

corners off!

Figure 16. Speed dial turned all the way down

to the lowest speed.

Workpiece

Center Line

Distances

Tool Rest

1

/

8

"

1

/

4

"

Figure 15. Tool rest set

1

⁄

8

" above the

centerline and

1

⁄

4

" away from workpiece.