Assembly – Shindaiwa T282 TRIMMER X7502824801 User Manual

Page 7

7

An Emission Control Label is located on the engine. (This is an EXAMPLE ONLY, information on label varies by en-

gine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 50 or 300 hour emission compliance period is the time span selected by the manufacturer certifying the en-

gine emissions output meets applicable emissions regulations, provided that approved maintenance procedures

are followed as listed in the Maintenance Section of this manual.

Assembly

This unit comes fully assembled with the exception of the cutting attachment

shield and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all the components required for a

complete unit and inspect unit and components for any damage.

■

Engine and shaft assembly

■

Cutting attachment shield

■

Cutting attachment

■

Owner’s/operator’s manual

■

Assembly Tool (s)

■

Emission Control Warranty Statement

■

Safety Glasses

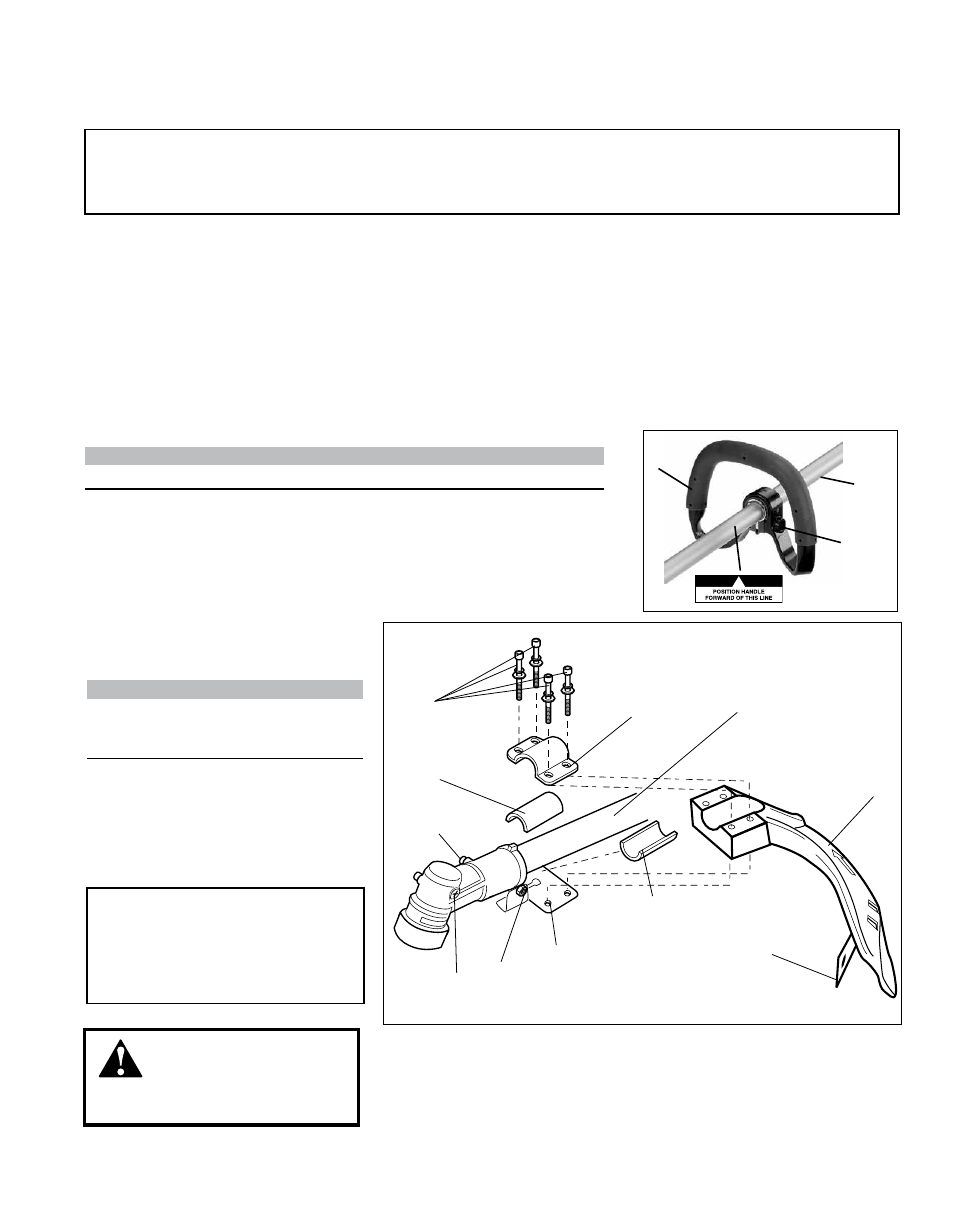

Cutting Attachment Shield

1. Insert the cutting attachment shield

between the outer tube and the cutting

attachment mounting plate.

CAUTION!

Make sure the clamp screw and

retaining nut are securely tightened

before tightening the four socket-head

cap screws.

NOTE:

It may be necessary to loosen the retain-

ing nut and clamp screw to adjust cutting

attachment shield mounting plate.

2. Fit the two shims and the bracket over

the outer tube and loosely install the

four socket-head screws.

3. Tighten the four socket-head cap

screws to secure the cutting attach-

ment shield.

Outer Tube

Socket-Head

Cap Screws

Clamp Screw

Retaining

Nut

Drain

Screw

Mounting Plate

Shim

Shim

Bracket

Cutting

Attachment

Shield

Line Cutter

T282

WARNING!

NEVER operate the unit

without the cutting attachment shield

installed and tightly secured!

Front handle installation

NOTE:

Label shows minimum spacing for front handle location.

1. Position front handle for comfortable operation and secure screw.

Screw

Outer

Tube

Handle

Handle