Operation – Woodstock STEELEX ST1000 User Manual

Page 36

-34-

ST1000 14" Bandsaw

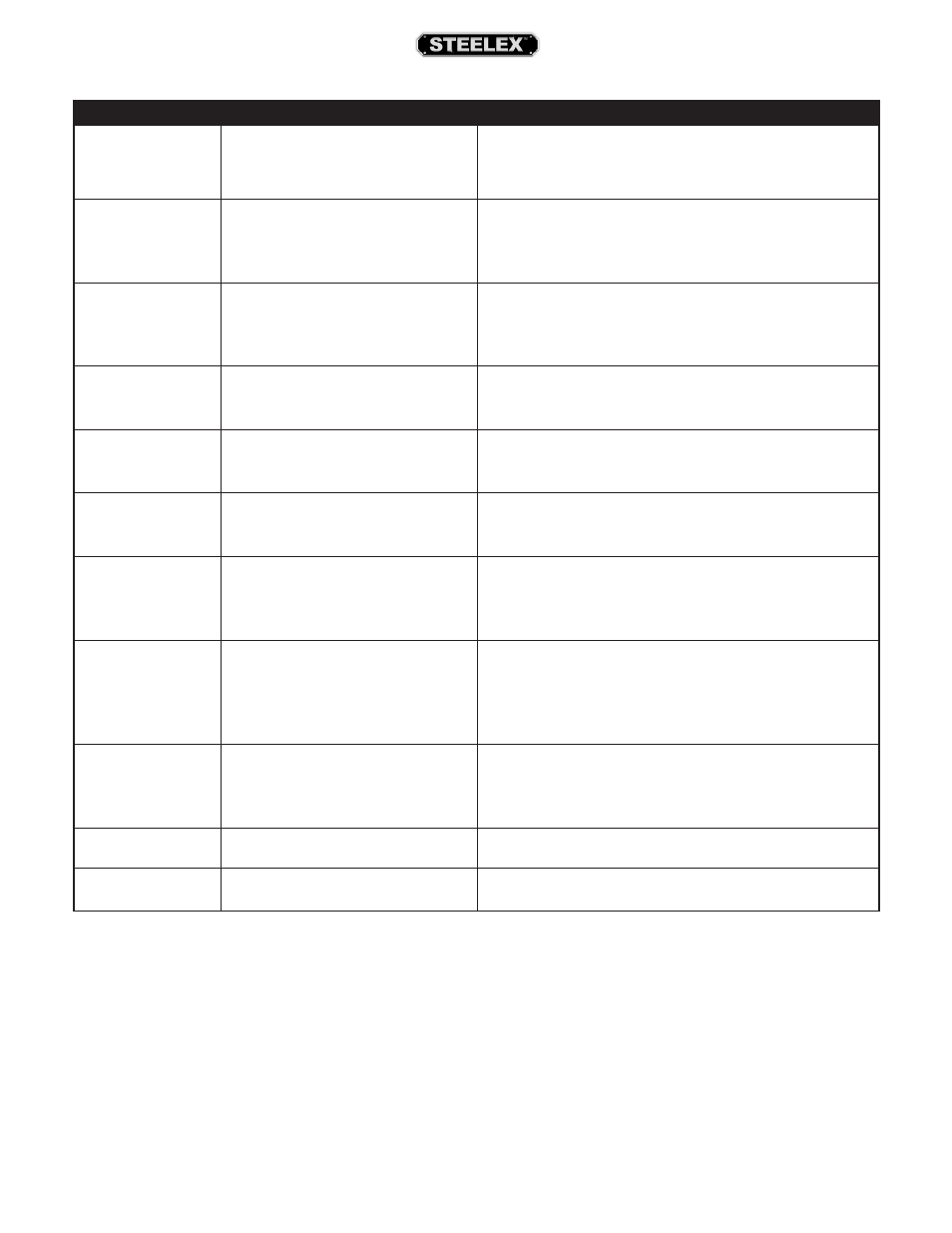

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Blade slows when cut-

ting. Blade makes a

squealing noise, espe-

cially on start-up.

1. V-belts loose.

2. V-belts worn out.

1. Tighten V-belts.

2. Replace V-belts.

Blade does not run

evenly on wheels or

runs off.

1. Tracking is not adjusted properly.

2. Rubber tire on wheel is damaged or

worn.

3. Wheels are not co-planar.

1. Adjust tracking.

2. Replace rubber tires.

3. Adjust wheel co-planarity.

Blade does not cut

evenly.

1. Blade tension is incorrect.

2. Tooth set is uneven.

3. Teeth are sharper on one side than the

other.

1. Adjust tension.

2. Replace blade, or have it professionally sharpened.

3. Replace blade, or have it professionally sharpened.

Wood cuts slow or

smokes during cut.

1. Worn or dull blade, missing teeth.

2. Blade installed backwards.

3. Wrong teeth per inch.

1. Replace blade.

2. Check blade rotation and reverse blade if necessary.

3. Use a blade with fewer teeth per inch.

Blade will not cut a

straight line.

1. Blade tension is incorrect.

2. Blade too narrow.

3. Blade guides need adjustment.

1. Adjust blade tension.

2. Use wider blade.

3. Adjust blade guides.

Blade comes off of

wheel.

1. Blade tension is incorrect.

2. Blade guides need adjustment.

3. Feeding workpiece too fast.

1. Adjust blade tension.

2. Adjust blade guides.

3. Feed workpiece slower.

Blade breaks frequent-

ly.

1. Blade tension is incorrect.

2. Blade guides need adjustment.

3. Cutting corners too sharply.

1. Adjust blade tension.

2. Adjust blade guides.

3. Use a wider arc on outside cuts, or use relief cuts to make tight

inside cuts.

Sawdust

build-up

inside wheel covers.

1. Clogged dust port.

2. Low CFM (airflow) from dust collection

system.

1. Clean out dust port.

2. Three options:

—Check dust lines for leaks or clogs.

—Move dust collector closer to saw.

—Install a stronger dust collector.

Burn marks on the

edge of the cut.

1. Too much side pressure when feeding

workpiece.

2. Blade too wide for size of radius being

cut.

1. Feed workpiece straight into the blade.

2. Install a smaller width blade, and/or increase blade tension.

Rough or poor quality

cuts.

1. Feeding workpiece too fast.

1. Reduce feed rate.

Blade contacting table

insert.

1. Excessive side pressure when cutting.

2. Table improperly adjusted.

1. Reduce side pressure.

2. Adjust table.

Operation