Description – JBL MPC User Manual

Page 4

3

Description

The MPC Series from JBL is a line of professional power amplifiers specifically designed for

contracting applications. There are six models, each with two independent channels. Each

model in the MPC Series line is available in a T version for driving either 200V, 140V, 100V,

70V, 50V, or 25V constant voltage lines and in a non-T versions for driving loudspeaker

systems with impedances as low as 2 ohms. (See section on bridging for information about

200V, 140V, and 50V drive capabilities).

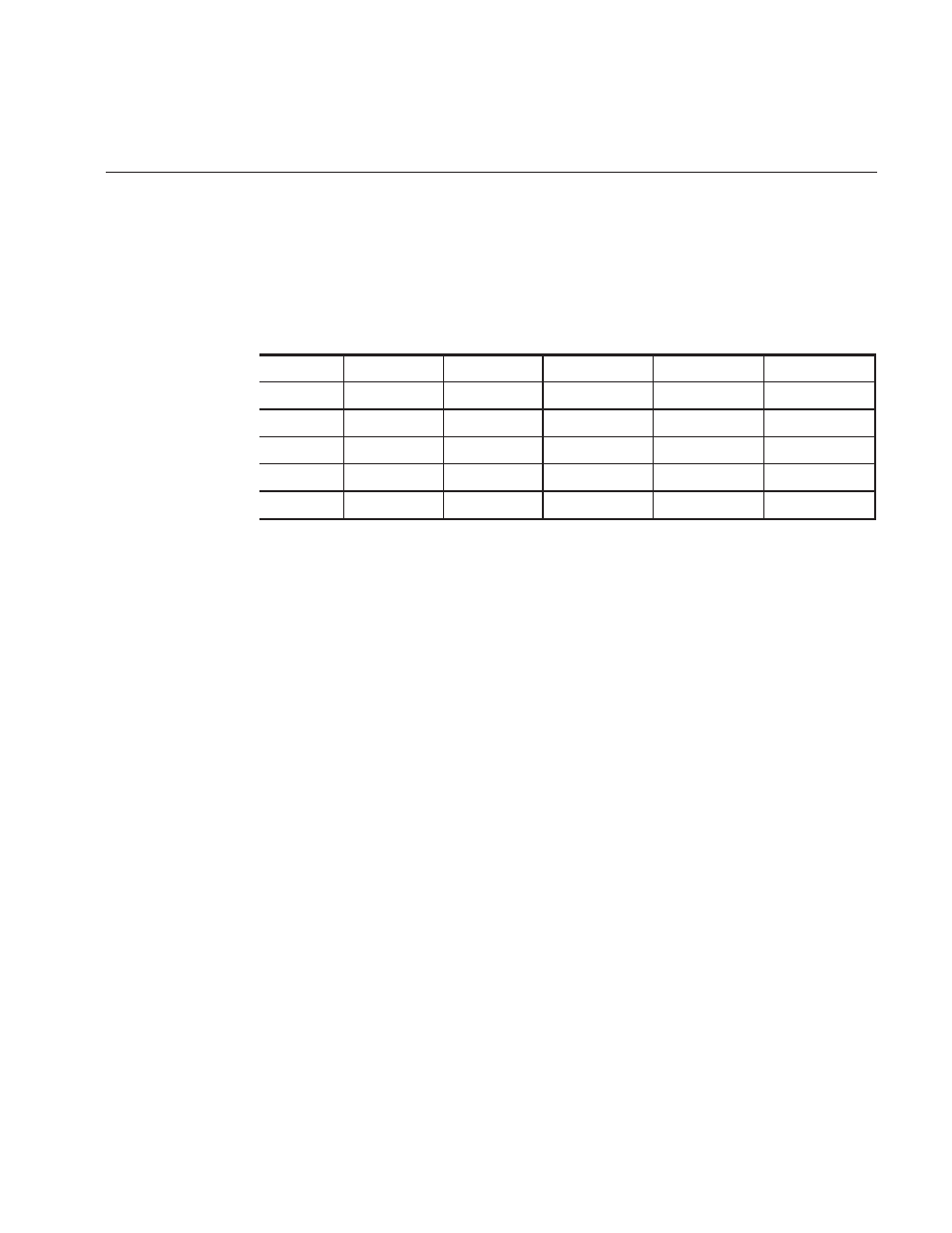

Power CapabilitiesThe table below lists the power ratings under various load conditions:

l

e

d

o

M

4

Ω

Ω

Ω

Ω

Ω

1

2

Ω

Ω

Ω

Ω

Ω

2

s

t

l

o

V

0

0

1

s

t

l

o

V

0

7

s

t

l

o

V

5

2

0

0

2

C

P

M

2

×

W

5

2

2

2

×

W

0

5

3

T

0

0

2

C

P

M

2

×

W

5

2

2

2

×

W

0

5

3

2

×

W

5

7

1

3

2

×

W

5

7

1

3

2

×

W

0

5

1

3

0

0

3

C

P

M

2

×

W

0

0

3

2

×

W

0

5

4

T

0

0

3

C

P

M

2

×

W

0

0

3

2

×

W

0

5

4

2

×

W

0

5

2

4

2

×

W

0

5

2

4

2

×

W

0

0

2

4

0

0

6

C

P

M

2

×

W

0

0

6

2

×

W

0

0

9

T

0

0

6

C

P

M

2

×

W

0

0

6

2

×

W

0

0

9

2

×

W

0

0

5

4

2

×

W

0

0

5

4

2

×

W

0

0

4

4

1

FTC watts per channel, 20 Hz20 kHz, 0.1% THD

2

EIA watts per channel, 1 kHz, 1% THD

3

Watts per channel, band limited for 50 Hz15 kHz response, 0.25% THD

4

Watts per channel, band limited for 45 Hz15 kHz response, 0.25% THD

Channel SeparationEach channel has its own power transformer secondary to provide

maximum audio separation (minimum sound leakage) between the two channels, minimizing

interaction that can otherwise occur on amplifiers with a common power supply.

High EfficiencyThe MPC200, 200T, 300 & 300T utilize complementary Class AB linear

output circuitry. For improved efficiency, the MPC600 and 600T utilize Class H step-linear

complementary output circuitry using multi-rail power supplies.

High Cooling CapacityEvery MPC amplifier features a large diameter two-speed fan and

massive extruded aluminum heat sinks. The output devices couple directly to the heat sink.

This provides better cooling of the output devices while eliminating problematic insulating

wafers that are an integral part of most other amplifier designs. Forced air cooling in a back-

to-front direction provides for more effective cooling, preventing problems that otherwise

occur from a continual heat build-up inside the equipment rack, which occurs in amplifiers

with front-to-back or side-to-side flow schemes. These design factors allow the MPC amplifi-

ers to work in high duty-cycle instances when many other professional amplifiers cannot.

Weight BalanceThe power transformers, as well as the output transformers on the T

models, are mounted in the front of the amplifier chassis, as close to the front mounting rails

as possible. This keeps the units center of gravity forward to minimize the twisting force on

the front mounting ears.

Rail SupportThe amplifier should be supported at all four corners, especially if it is in a

portable rack. The flow-through cooling scheme allows you to rack-mount the amplifiers on

top of the other, with no clearance necessary in between. This mounting technique also helps

support the weight of the upper amplifiers. In permanent fixed installations, the rear of the

amplifiers can receive physical support by installing the amplifiers at the bottom of the

equipment rack. Make sure that the direct weight of the back of the amplifier is supported

from the bottom of the rack.

Dimensions

a) HeightThe MPC200 and 200T are 2 rack spaces high. The MPC300, 300T, 600 and

600T are 3 rack spaces high.