Storage – McCulloch MC30 User Manual

Page 19

26

STORAGE

Immediately prepare your riding mower for

stor age at the end of the season or if the

riding mower will not be used for 30 days

or more.

WARNING: Never store the riding mower

with gas o line in the tank inside a building

where fumes may reach an open flame or

spark. Allow the engine to cool before stor-

ing in any en clo sure.

MOWER

Remove deck from mower for winter storage.

When mower is to be stored for a period of

time, clean it thor oughly, remove all dirt,

grease, leaves, etc. Store in a clean, dry area.

1. Clean entire riding mower (See “CLEAN-

ING” in the Maintenance section of this

manual).

2. Inspect and replace belt, if nec es sary

(See belt re place ment in struc tions in the

Service and Ad just ments section of this

manual).

3. Lubricate as shown in the Main te nance

section of this man ual.

4. Be sure that all nuts, bolts and screws

are securely fastened. In spect moving

parts for damage, break age and wear.

Replace if nec es sary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before paint ing.

BATTERY

• Fully charge the battery for storage.

• If battery is removed from riding mower

for storage, do not store battery directly

on concrete or damp surfaces.

ENGINE

FUEL SYSTEM

IMPORTANT: It is important to prevent

gum deposits from forming in essential fuel

system parts such as carburetor, fuel hose,

or tank during storage. Also, alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage.

• Empty the fuel tank by starting the engine

and letting it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor clean er

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable al-

ternative in min i miz ing the formation of fuel

gum deposits during stor age. Add stabilizer

to gasoline in fuel tank or stor age container.

Always follow the mix ratio found on stabilizer

container. Run engine at least 10 minutes

after adding stabilizer to allow the sta bi liz er to

reach the carburetor. Do not empty the gas

tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace

with clean engine oil. (See “ENGINE” in the

Maintenance section of this man ual).

CYLINDER(S)

1. Remove spark plug(s).

2. Pour one ounce of oil through spark plug

hole(s) into cylinder(s).

3. Turn ignition key to “START” po si tion for

a few seconds to distribute oil.

4. Replace with new spark plug(s).

OTHER

• Do not store gasoline from one sea son to

another.

• Replace your gasoline can if your can starts

to rust. Rust and/or dirt in your gasoline

will cause problems.

• If possible, store your riding mower in doors

and cover it to give protection from dust

and dirt.

• Cover your riding mower with a suitable

protective cover that does not retain mois-

ture. Do not use plastic. Plas tic cannot

breathe which allows con den sa tion to form

and will cause your riding mower to rust.

IMPORTANT: Never cover riding mower

while en gine and exhaust areas are still

warm.

19

RIDING MOWER

Always observe safety rules when per form ing

any main te nance.

BRAKE OPERATION

If riding mower requires more than four (4)

feet to stop at highest speed in high est gear

on a level, dry concrete or paved surface,

then brake must be serviced at your nearest

authorized service center.

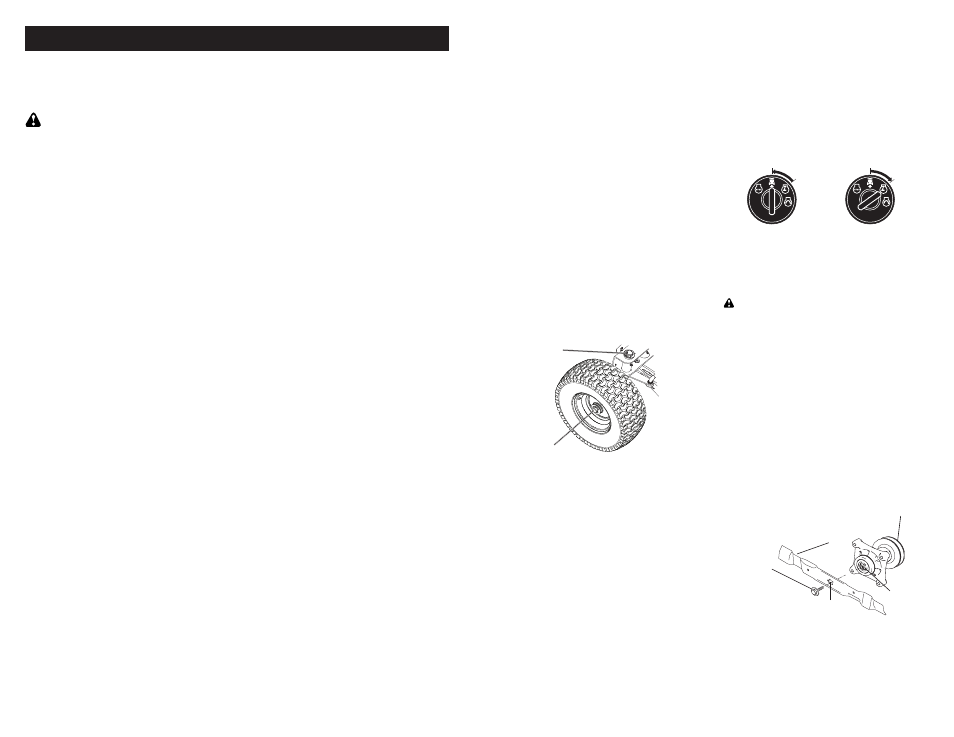

TIRES

• Maintain tire pressure at 12 PSI.

• Keep tires free of gasoline, oil, or insect

control chemi cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and pre vent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also pre vents tire dry rot and

corrosion.

AXLE AND SPINDLES

• Front wheel axles and front spindles should

be properly lubricated.

• Wheel axles and spindles should be

lubricated with grease.

Wheel Axle

Spindle

OPERATOR PRESENCE SYS TEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation sys tems are work ing properly.

If your riding mower does not function as

described, repair the problem immediately.

• The engine should not start unless the

brake pedal is fully de pressed, and the deck

clutch lever is in the dis en gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• When the engine is running, any attempt

by the op er a tor to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the deck

clutch lever is engaged, any attempt by

the operator to leave the seat should shut

off the engine.

• Never operate the deck clutch lever unless

you are seated in the seat.

BLADE CARE

For best results mower blades must be sharp.

Re place worn, bent or damaged blades.

CAUTION:

Use only a replacement blade

approved by the manufacturer of your riding

mower. Using a blade not approved by the

manufacturer of your riding mower is hazard-

ous, could damage your riding mower and

void your warranty.

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engine is running with the ignition

switch in the engine "ON" position and the

deck clutch lever engaged, any attempt by

the operator to shift into reverse should

shut off the engine.

• When the engine is running with the ignition

switch in the ROS "ON" position and the

deck clutch lever engaged, any attempt by

the operator to shift into reverse should

NOT shut off the engine.

BLADE REMOVAL

1. Raise mower to highest position to allow

access to blade.

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning coun ter-

clock wise.

3. Install new blade with stamped "THIS

SIDE UP" facing deck and mandrel as-

sembly.

IMPORTANT: To ensure proper as sem bly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt securely

(45-55 Ft. Lbs.).

IMPORTANT: Special blade bolt is heat

treated.

025

45

Blade

Center Hole

Star

Mandrel

Assembly

Blade Bolt

(Special)

ROS "ON"

Position

Engine "ON" Position

(Normal Operating)