English – Middleby Marshall PS314SBI User Manual

Page 9

9

ENGLISH

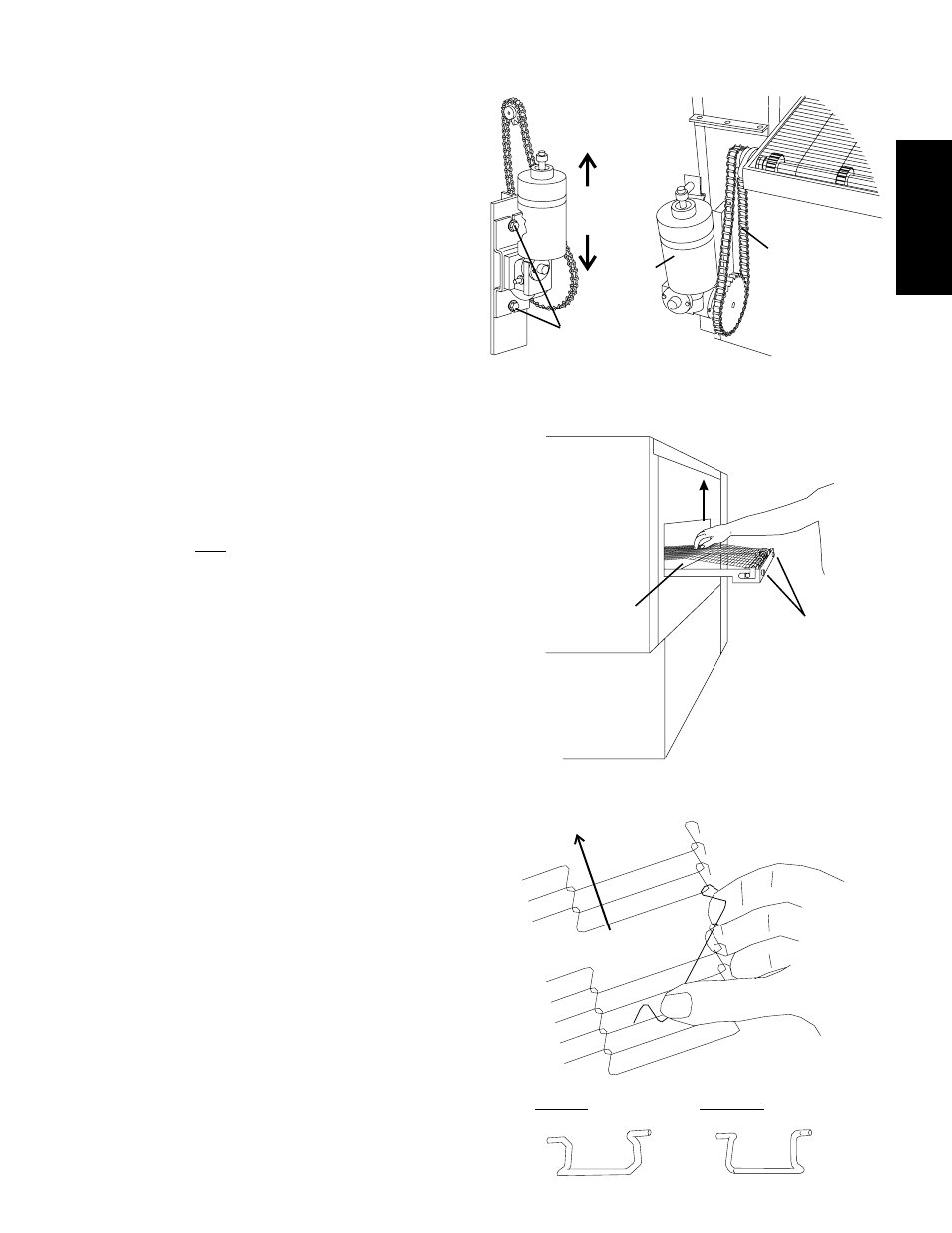

3. Install the drive chain between the conveyor drive sprocket

and the motor sprocket as shown in Figure 2-10. Then,

check the tension of the drive chain. The chain should have

a 1/2" (13mm) deflection.

If necessary, the motor can be repositioned to allow the

chain to be installed, or to correct the tension of the chain

after it is in place. To reposition the motor:

Loosen the two hex head screws that fasten the

conveyor motor's mounting bracket to the oven. The

screws are shown in Figure 2-10.

Raise or lower the motor slightly, as required. Tighten

the two hex screws, and check the chain tension.

Repeat these steps as necessary until the drive chain

has the correct 1/2" (13mm) deflection.

4. Check the tension of the conveyor belt at the IDLER (right)

end of the conveyor, by lifting the center of the belt straight

up with your fingers as shown in Figure 2-11. The belt

should lift between 2-3" (50-75mm). DO NOT OVER-

TIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor. See Figure 2-11.

5. Check for freedom of movement of the conveyor belt by

pulling it for about 2-3 feet (60 to 90 cm) with your fingers.

The conveyor must move freely.

6. If necessary, links can be added to or removed from the

conveyor belt to achieve the correct deflection of 2-3" (50-

75mm). If links must be removed from the belt, it can be

reattached to the conveyor as follows:

a. The conveyor belt links must be oriented as shown in

Figure 2-12.

b. The smooth side of the conveyor belt must face UP.

c. Connect the inside master links. Check that the links

are oriented as shown in Figure 2-12.

d. Connect the outside master links. Note that the

outside master links have right and left sides. The

right-side master link has an open hook facing you, as

shown in Figure 2-12.

e. Return to Step 4, above, to re-check the belt tension.

SECTION 2 - INSTALLATION

Figure 2-10 - Drive Motor and Drive Chain

Loosen hex screws and

slide motor up or down to

adjust belt tension

Drive chain

Motor

Figure 2-11 - Conveyor belt tension

Belt deflection

should be 2-3

(50-75mm)

Lift belt straight

up as shown

Adjust tension by

turning screws (2)

Figure 2-12 - Master link orientation

Direction of

travel

Correct outside

master link

orientation

CORRECT inside master

link orientation

INCORRECT inside master

link orientation