Carving the hull, Carving the bulwarks, Carving the inside of the transom & counter – Model Shipways 2003 User Manual

Page 5

5

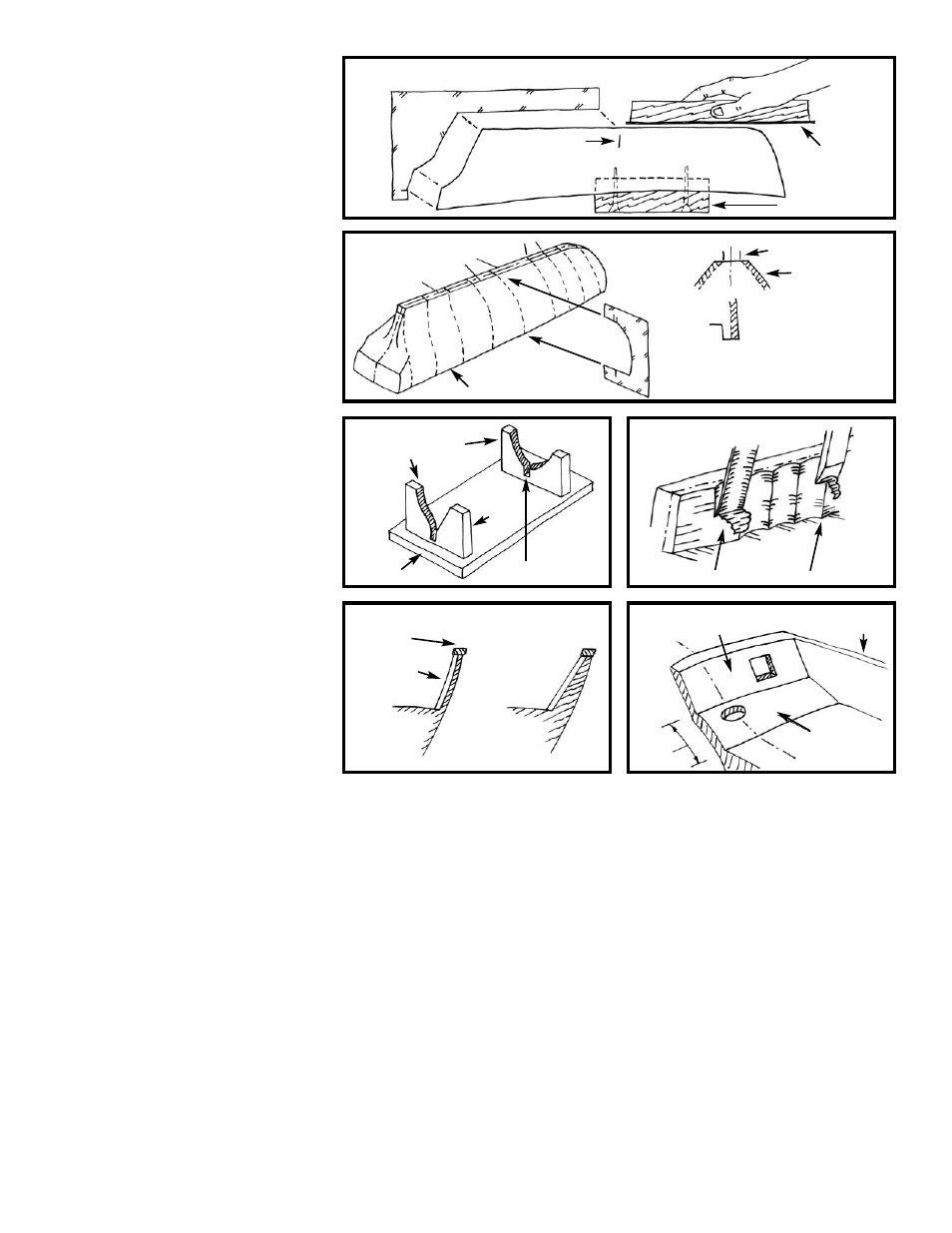

2. Carving the Hull

Cut a wooden block from scrap to about 3”

x 1” x 3/4” thick. Screw the block to the

deck so the model can be held in a bench

vise for carving. First, check the accuracy of

the profile and correct it as necessary, using a

long sanding block (Figure A-2).

Next, mark the centerline, rabbet lines

(where hull meets keel) and station lines on

the model (Figure A-3). Place the station

marks on the center of the hull bottom and

on top of the rails so the marks won’t be

carved off as you work. Also, add the

breadth marks on the rail if you elected the

option noted above.

Start carving approximately at Station 5

(maximum beam) and progress forward,

then aft, using chisels and gouges to cut

away excess wood. Avoid carving against the

grain by shifting forward or aft of Station 5

until you find a spot where you are going

with the grain. Basswood carves easily, so

you probably won’t have much problem with

the grain.

Carve very slowly and take off a little wood

at a time. Fit the templates as you go. Carve

until the template fits reasonably well, then

use sandpaper to obtain the final shape. At

first the templates will not fit very well. You

must compare the template to the hull and

visually decide where to remove wood. Cut a

little off, then re-check the template.

Finally, draw a few horizontal pencil lines

(like waterlines) and the vertical station lines

on the hull. Use these to visually check the

shape of the hull. Hold the hull at various

angles, and look to see if the pencil lines are

fair (even). If you have any unfairness, dips

or bump, they can usually be found with this

visual check. You can also use a stiff stick of

wood, about 1/8” square, and lay it on the

hull at various locations. Dips in the hull

will show up under the stick.

Sand the stern transom with a sanding block.

3. Carving the Bulwarks

Make yourself a temporary cradle to secure

the hull while carving (Figure A-4). This

cradle also will serve to hold the model for

most of the remaining work. Make the cra-

dle so the model sits in it with its waterline

parallel to the baseboard and table. The

tops of the cradle should be below the

waterline. Later, when you are ready to

paint, attach a pencil on top of a wooden

block and slide it along the table to mark

the location of the waterline.

The machine-carved hull has bulwarks thick-

er than scale so they won’t break while inside

the kit box. The upper surface is cut to the

underside of the cap rail. After you carve the

outside of the hull, the bulwarks will be

thinner. If more than 1/16" thick, it will be

necessary to carve the inside of the bulwarks.

This is the most difficult part, so work slow-

ly as you carve (Figure A-5). After carving,

sand the surfaces smooth. If you happen to

have or want to buy a powered rotary tool

like a Dremel, there are many cutters avail-

able to quickly reduce the bulwark thickness.

Note that bulwark stanchions go onto the

inboard side of the bulwarks. Together with

the bulwark (planks on a real ship) they

must fit under the cap rail which is only

5/32" wide. If the stanchions will not fit,

make them a little thinner, or better, sand

the inside of the bulwark a little more at the

top. You can then taper the inside down to

the deck without reducing the thickness at

the deck. You won’t really see that the bot-

tom is thicker than the top. Of course, you

could use a wider cap rail but don’t get it too

wide or the scale will not look proper. Figure

A-6 is a cross section through the bulwark

showing the options.

4. Carving the Inside of the

Transom & Counter

The top of the transom should be about

3/32" thick. If necessary, carve the transom

down on the inside, tapering to the counter

line. Like the bulwarks, a rail sits atop the

transom. The counter is that portion of the

stern from the transom down to the deck.

This should be a slightly curved shape. See

Figure A-7 for a transom and counter view.

The sketch also shows the openings that will

be cut later.

Transom Option - On a machine-carved

hull the wood grain at the stern is in the

wrong direction. If you are worried that the

transom might split, you could add a thin

basswood sheet on the outside to strengthen

it. You could even cut out the transom com-

pletely and add a sheet transom.

At this stage, the basic hull is fully carved.

Sand the entire hull with #220 grit sandpa-

per for the final smoothing. Be careful not to

round the upper edges of the rail or at the

rabbet. These should be sharp corners.

FIG. A-2 CORRECTING THE PROFILE

FIG. A-3

MARKING THE HULL

FIG. A-4 CRADLE

FIG. A-6 BULWARK SECTIONS

FIG. A-7 TRANSOM & COUNTER

FIG. A-5 CARVING

BULWARKS

TEMPLATE

MARK STATIONS

MARK RABBET

STA 4

STA 7

1/4"

3/8" PLYWOOD

CAP RAIL

CL

TRANSOM

SLIGHT

CURVE

BULWARK

COUNTER

DECK

STANCHION

UNIFORM THICKNESS

THICKER AT DECK

CUT SLOT

FOR KEEL

MARK

CENTER LINE

FIT TEMPLATES

USE GOUGE FIRST

SMOOTH WITH CHISEL

MARK STATIONS ON TOP OF RAIL

CROSS SECTION

RAIL

CL

RABBET

WOOD TO

BE CUT AWAY

SANDING BLOCK

BENCH VISE BLOCK

STATION

5