Push stick, Ripping – Makita 2702X1 User Manual

Page 9

9

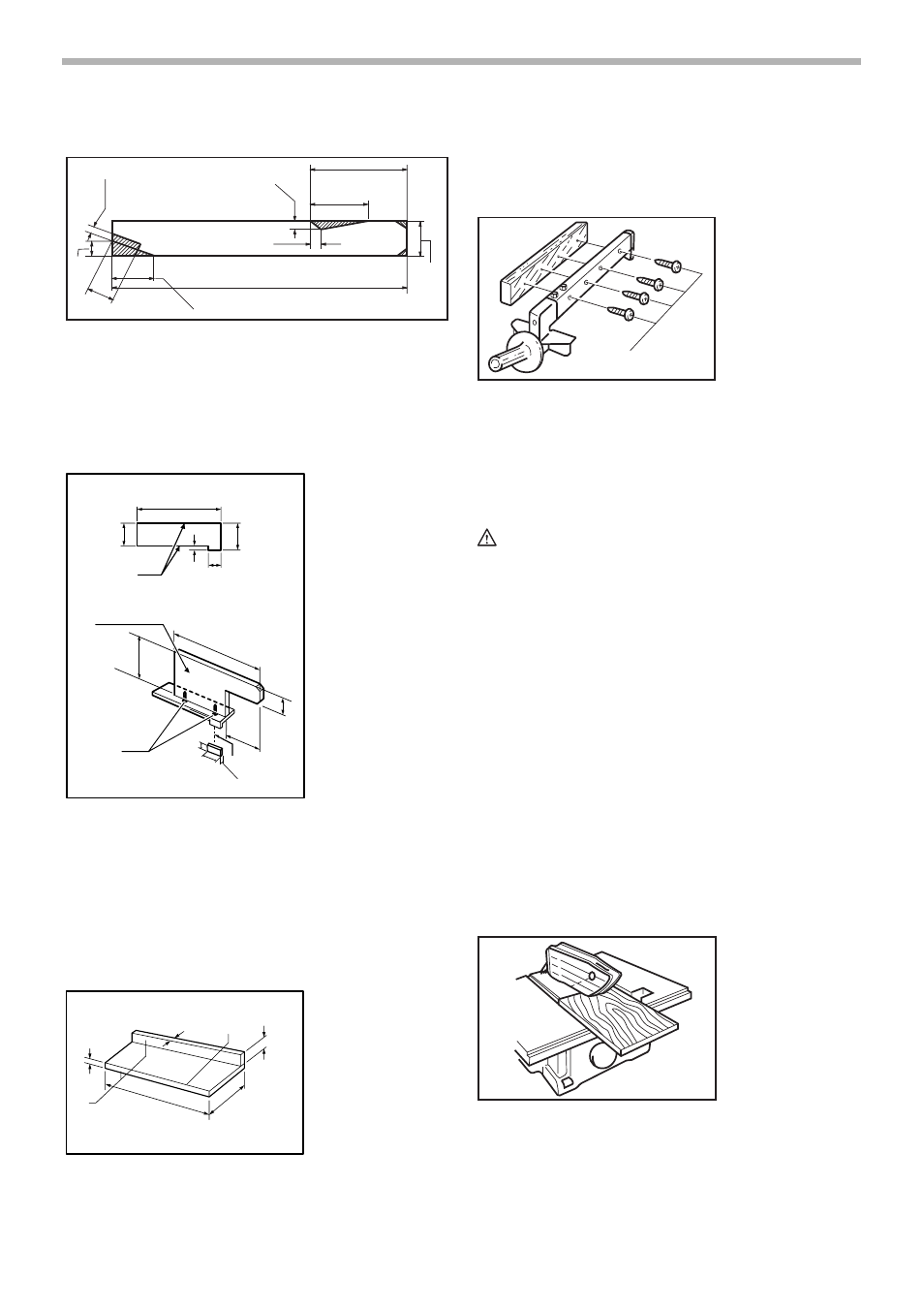

Push stick

A push stick can be easily made from a piece of plywood

19 mm (3/4”) to 25 mm (1”) thick.

Cut out the hatched area on the stick and smooth edges

with a file. (H) dimension should be less than 12.7 mm (1/

2”) so as to be thinner than the workpiece.

Push block

Use a 19 mm (3/4”) piece of plywood.

Handle should be in center of plywood piece. Fasten with

glue and wood screws as shown. Small piece 9.5 mm x 8

mm x 50 mm (3/8” x 5/16” x 2”) of wood must always be

glued to plywood to keep the blade from dulling if the

operator cuts into push block by mistake. (Never use

nails in push block.)

Auxiliary fence

Make auxiliary fence from 9.5 mm (3/8”) and 19 mm (3/

4”) plywood pieces.

Fasten with glue and wood screws.

Wood facing (rip fence)

A wood facing should be used for operations when the

blade comes close to the rip fence. Wood facing for the

rip fence should be the same size as the rip fence. Make

sure the bottom of facing is flush with the table surface.

Ripping

CAUTION:

•

When ripping, remove the miter gauge from the

table.

•

When cutting long or large workpieces, always

provide adequate support behind the table. DO

NOT allow a long board to move or shift on the

table. This will cause the blade to bind and increase

the possibility of kickback and personal injury. The

support should be at the same height as the table.

Before operating the table saw, check to be sure that the

antikickback pawls operate properly. Turn the tool off and

unplug it. Feed the workpiece under the blade guard and

along both sides of the blade to simulate cutting. Try to

withdraw the workpiece on each side by pulling it toward

you. The antikickback pawls should grab the workpiece

and prevent it from moving back toward the operator.

Always keep the antikickback pawls sharp so they will

operate properly. Keep them sharp by using a round-

shaped file to maintain the original shape of the pawls.

1.

Adjust the depth of cut a bit higher than the thick-

ness of the workpiece.

2.

Position the rip fence to the desired width of rip and

lock in place by lowering the grip. Before ripping,

make sure the rear end of the rip fence is secured

firmly. If it is not secured enough, follow the proce-

1. Face/edge par-

allel

2. Handle

3. Wood screw

4. Glue together

1. Face/edge par-

allel

(H)

19mm

(3/4")

40mm

(1-1/2")

50mm(2")

380mm(15")

9.5mm(3/8")

75mm(3")

130mm(5")

9.5mm(3/8")

50mm

(2")

006876

120mm

(4-3/4")

300mm(12")

130mm(5")

50mm(2")

6mm

(1/4")

300mm(12")

130mm

(5")

100mm

(4")

50mm

(2")

9.5mm

(3/8")

50mm

(2")

8mm(5/16")

1

2

3

4

006219

9.5mm

(3/8")

19mm

(3/4")

120mm

(4-3/4")

40mm

(1-1/2")

140mm

(5-1/2")

460mm

(18")

1

006211

1. No.10 wood

screws (long

enough to pene-

trate halfway

into facing)

1

006883

006886