5. adjusting engine speed (honda-powered units) – Miller Electric BLUE STAR 6000 TM-499C User Manual

Page 25

TM-499 Page 21

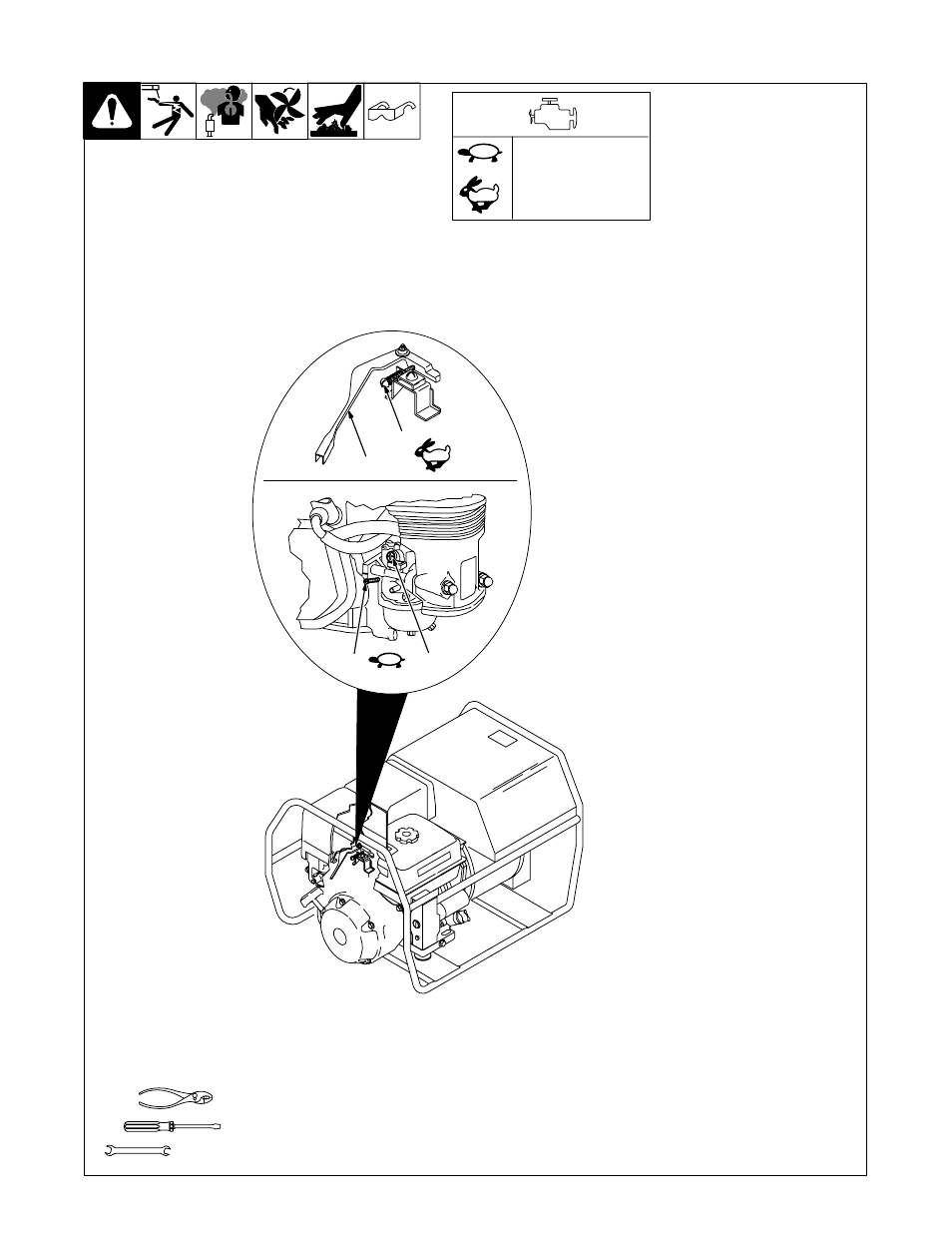

7-5. Adjusting Engine Speed (Honda-Powered Units)

802 097-A

After tuning engine, check engine

speeds. See table for proper no

load speeds. If necessary, adjust

speeds as follows:

Start engine and run until warm.

Weld/Power Speed

Adjustment

1

Throttle Control Lever

2

Adjustment Screw

Move lever to Run (60 Hz) position.

Turn screw and move lever until en-

gine runs at weld/power speed.

Idle Speed Adjustment

3

Pilot Screw

4

Throttle Stop Screw

Move lever to idle position. Turn pi-

lot screw until engine runs at high-

est idle speed. Turn stop screw until

engine runs at rated idle speed

(normally about 2-1/4 turns out.)

Y Stop engine. Close fuel

valve.

1/4, 3/8 in

Tools Needed:

1400

±

150 rpm

3720

±

50 rpm (60 Hz)

3250

±

50 rpm (50 Hz)

2

1

3

4

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)