3. typical equipment location, 4. installing drive rolls – Miller Electric AA40GBU User Manual

Page 14

OM-227 674 Page 10

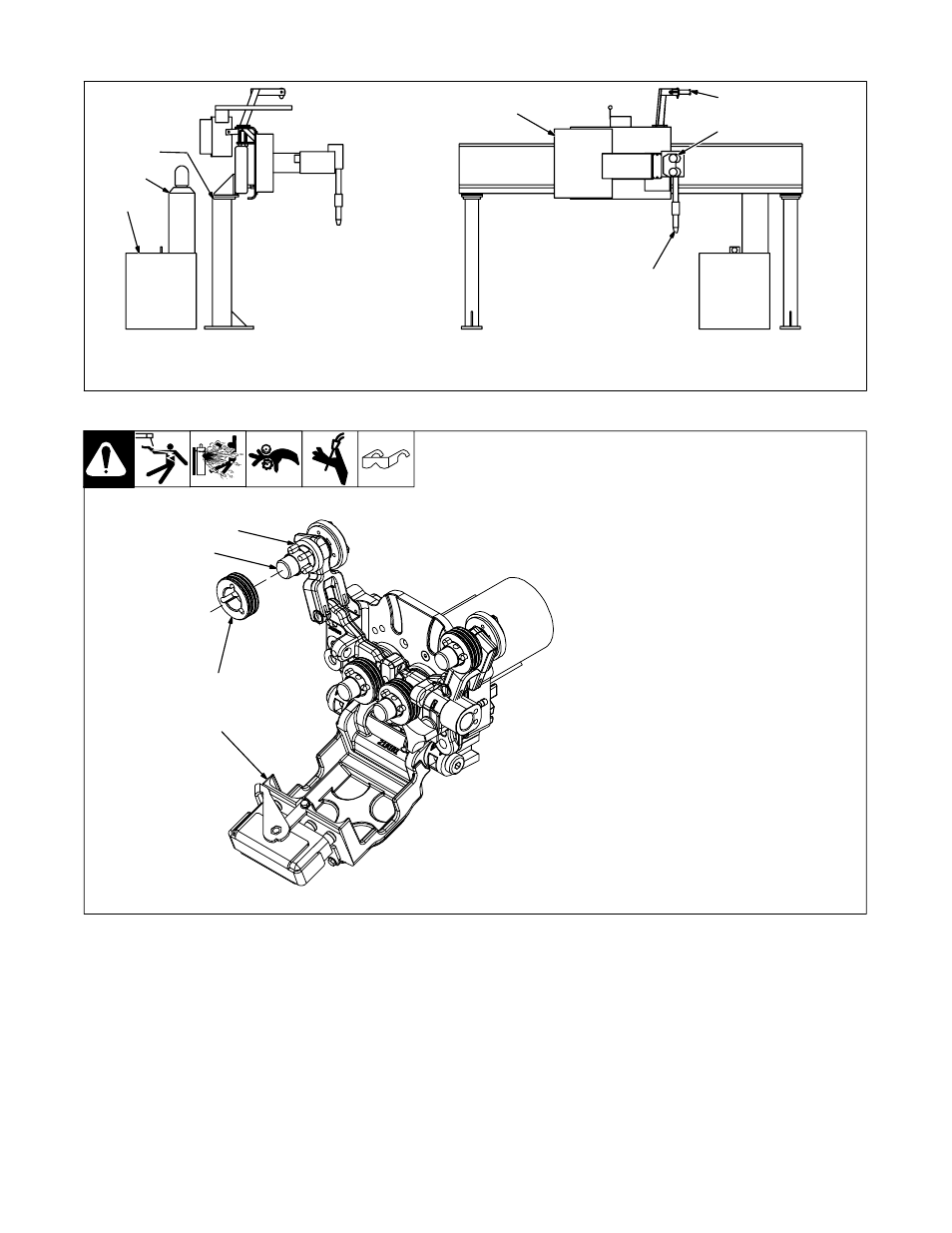

3-3. Typical Equipment Location

ST-131 138-A

1

Welding Power Source

2

Gas Cylinder

3

Side Beam

4

Weld Control

5

Spool Support

6

Wire Drive Assembly

7

Automatic Welding Gun

1

2

3

4

5

6

7

3-4. Installing Drive Rolls

804 187-A

1

Pressure Assembly Door

2

Drive Roll

3

Ejector Button

4

Drive Roll Carrier

Installation

Open pressure assembly door.

Align drive roll slots with three lobes

on drive roll carrier.

Insert drive roll onto carrier. Drive

roll will snap into place.

Removal

.

Remove PD wire guide before

removing lower drive rolls.

Lift up drive roll swing arm and

press ejector button in middle of

drive roll carrier.

.

If ejector button does not re-

turn to normal position (out),

install a drive roll and ejector

button will pop out.

1

2

4

3

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)