1. teach points explained – Miller Electric OM-1589 User Manual

Page 40

OM-1589 Page 34

SECTION 12 − TEACH POINTS

12-1. Teach Points Explained

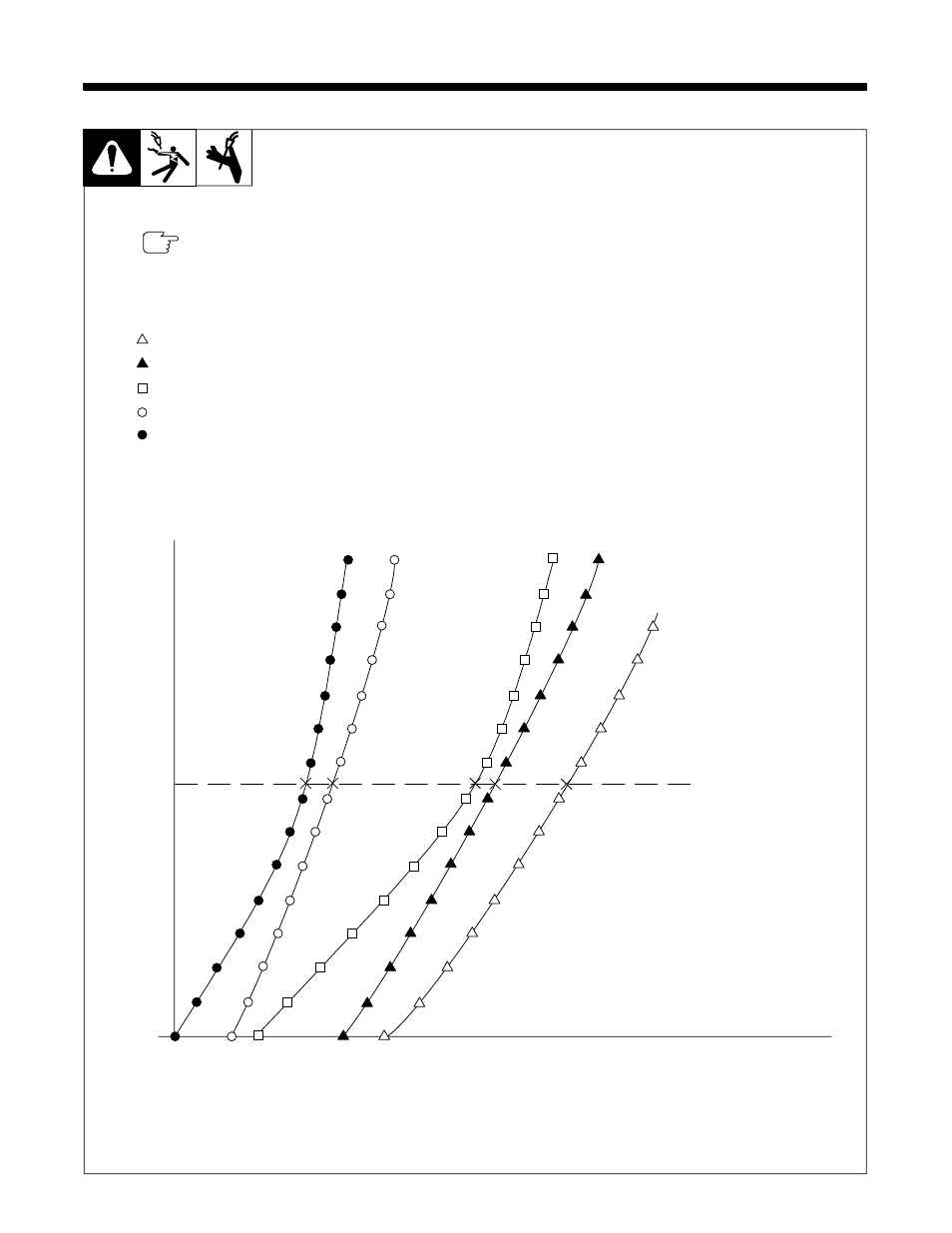

The teach mode allows the user to

create custom pulse programs. The

teach mode has 15 teach points. At

each teach point, the user can ad-

just five parameters to shape the

pulse waveform of the weld output.

The six parameters are: IPM

(MPM), Apk, Abk, Vpk, PPS, and

PWms.

Apk, Vpk, Abk, PPS, and PWms

acting together provide the energy

necessary to burn off welding wire

at a set wire feed speed. The graph

below shows that as wire feed

speed increases, energy increases

(Apk, Vpk, Abk, PPS, and PWms

acting synergically).

Under some conditions, the wire

feeder limits wire feed speed to

maintain all pulse parameters with-

in the capability of the system.

100

180

210

240

270

300

330

360

370

420

450

480

510

540

565

Apk

10

20

30

40

50

60

70

80

90

100

110

120

130

140

200

Abk

20

55

80

105

130

160

185

210

235

260

290

315

340

365

400

PPS

1

3

5

PWms

2

4

875

820

765

710

655

600

545

490

435

380

325

270

215

160

85

IPM

Apk

Abk

PPS

PWms

Example Of A Synergic

Setting For 525 IPM With

All Teach Points Set At 55

IPM Increments

Apk = Peak Amperage

Abk = Background Amperage

PPS = Pulses Per Second

PWms = Pulse Width (Milliseconds)

See GMAW-P (Pulsed MIG) Process Guide (MILLER

Part No. 158 920) supplied with unit for more

information.

Vpk = Peak Voltage

10

18

21

24

27

30

33

36

37

42

45

48

51

54

56

Vpk

Vpk