Technical data – Graco HIGH-FLO 220-569 User Manual

Page 40

40

307-809

Technical Data

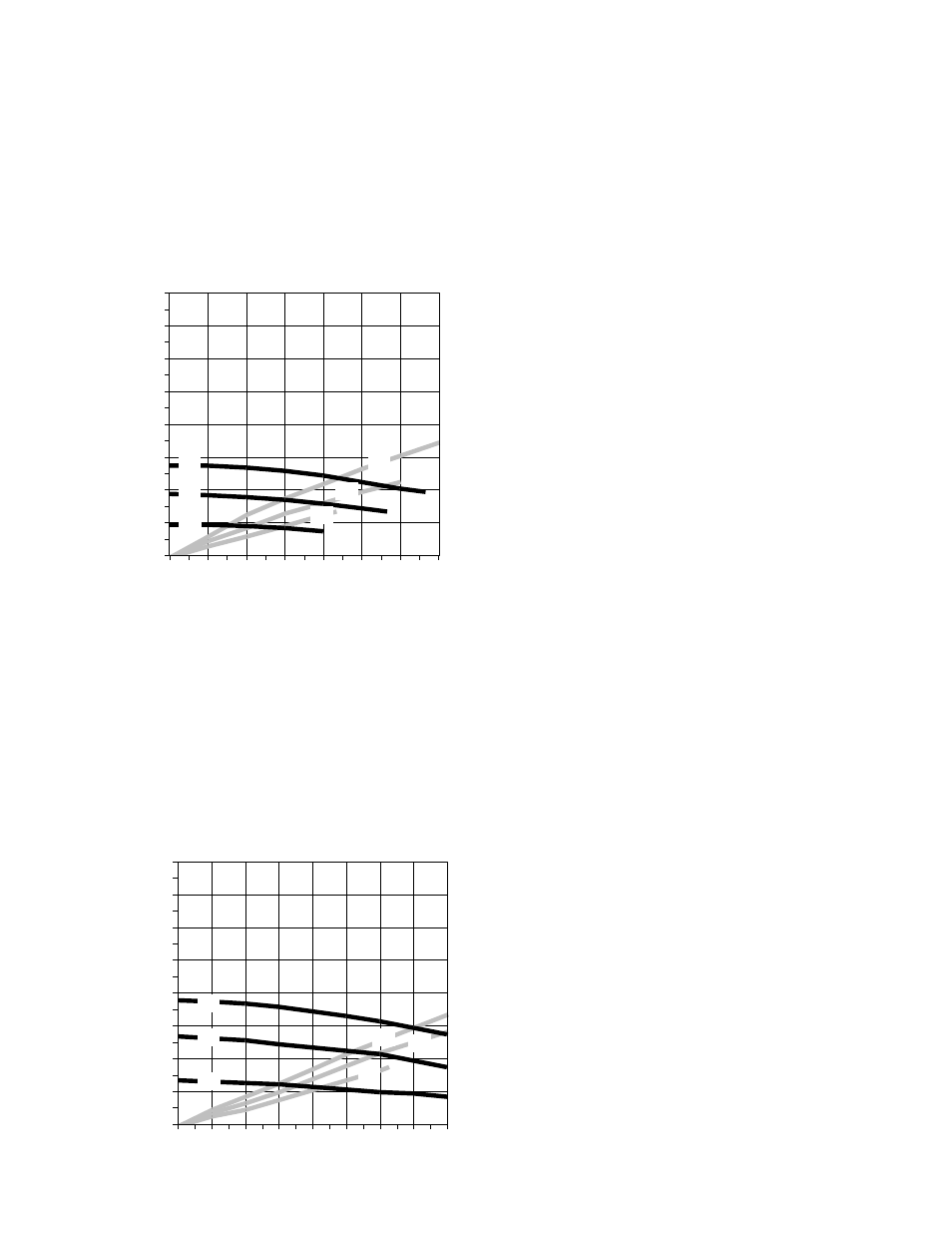

1.5:1 Ratio President Pumps, Models 220–559 and 220–562

Maximum Working Pressure

1.9 MPa, 19 bar (270 psi)

. . . . .

Air Operating Range 0.1–1.2 MPa, 1.4–12 bar (20–180 psi)

.

Air Consumption

See Performance Chart

. . . . . . . . . . . . . . . . .

Continuous Duty Delivery

75 liter/min (20 gpm)

. . . . . . . . . . . .

Pump Cycles Per Liter (gallon)

0.80 (3.0)

. . . . . . . . . . . . . . . . .

Maximum Recommended Pump Speed

60 cycles/min

. . . . .

Air Inlet

1/2 npt(f)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Inlet

1–1/2” npt(f)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Outlet

1” npt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted Parts

Model 220–559

Carbon Steel, Stainless Steel,

. . . . . . . . .

Ultra-High Molecular Weight Polyethylene, Leather, PTFE

r

Model 220–562

Chrome-Plated Stainless Steel,

. . . . . . . .

Ultra-High Molecular Weight Polyethylene, Leather, PTFE

r

0

50

100

150

200

250

300

350

400

0

3

6

9

12

15

18

21

10

18

27

36

45

54

11

23

34

46

57

68 79

GPM

l/min

CPM

1.4, 14

0.7, 7

30

20

10

0

1.96

0.84

0.28

CFM

m

3

/min

PSI

PUMP

OUTLET PRESSURE

AIR CONSUMPTION

63

1.05, 10.5

0.35, 3.5

1.7, 17

2.45, 24.5

70

0.56

MPa, BAR

2.1, 21

2.8, 28

40

1.12

50

1.40

60

1.68

A

B

C

A

B

C

To find Outlet Pressure (MPa/bar/psi) at a specific

delivery (liter/min or gpm) and operating air pressure

(MPa/bar/psi):

1. Locate desired delivery along bottom of chart.

2. Read vertical line up to intersection with

selected fluid outlet pressure curve (black

curves). Curve slopes from left to right.

Follow left to scale and read outlet pressure.

To find Pump Air Consumption (m

3

/min or

CFM/min) at a specific delivery (liter/min or gpm)

and operating air pressure (MPa/bar/psi):

1. Locate desired delivery along bottom of chart.

2. Read vertical line up to intersection with

selected air consumption curve (gray curves).

Curve slopes from right to left. Follow right to

scale and read air consumption.

A 0.7 MPa, 7 bar (100 psi) air pressure

B 0.49 MPa, 4.9 bar (70 psi) air pressure

C 0.28 MPa, 2.8 bar (40 psi) air pressure

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

2:1 Ratio President Pumps, Models 220–560 and 220–563

Maximum Working Pressure

2.5 MPa, 25 bar (360 psi)

. . . . .

Air Operating Range 0.1–1.2 MPa, 1.4–12 bar (20–180 psi)

.

Air Consumption

See Performance Chart

. . . . . . . . . . . . . . . . .

Continuous Duty Delivery

55 liter/min (14.6 gpm)

. . . . . . . . . . .

Pump Cycles Per Liter (gallon)

1.0 (4.1)

. . . . . . . . . . . . . . . . . .

Maximum Recommended Pump Speed

60 cycles/min

. . . . .

Air Inlet

1/2 npt(f)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Inlet

1–1/2” npt(f)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Outlet

1” npt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted Parts

Model 220–560

Carbon Steel, Stainless Steel,

. . . . . . . . .

Ultra-High Molecular Weight Polyethylene, Leather, PTFE

r

Model 220–563

Chrome-Plated Stainless Steel,

. . . . . . . .

Ultra-High Molecular Weight Polyethylene, Leather, PTFE

r

0

50

100

150

200

250

300

350

400

0

2

4

6

8

10 12 14 16

PUMP

OUTLET PRESSURE

AIR CONSUMPTION

8 16 25 33 41 49

CPM

57

8

15 23 30 38 46 54

GPM

l/min

62

30

20

10

0

1.96

0.84

0.28

CFM

m

3

/min

70

0.56

40

1.12

50

1.40

60

1.68

66

A

B

C

A B

C

PUMP DELIVERY (Test Fluid: No. 10 Motor Oil)

1.4, 14

0.7, 7

PSI

1.05, 10.5

0.35, 3.5

1.7, 17

2.45, 24.5

MPa, BAR

2.1, 21

2.8, 28

To find Outlet Pressure (MPa/bar/psi) at a specific

delivery (liter/min or gpm) and operating air pressure

(MPa/bar/psi):

1. Locate desired delivery along bottom of chart.

2. Read vertical line up to intersection with

selected fluid outlet pressure curve (black

curves). Curve slopes from left to right.

Follow left to scale and read outlet pressure.

To find Pump Air Consumption (m

3

/min or

CFM/min) at a specific delivery (liter/min or gpm)

and operating air pressure (MPa/bar/psi):

1. Locate desired delivery along bottom of chart.

2. Read vertical line up to intersection with

selected air consumption curve (gray curves).

Curve slopes from right to left. Follow right to

scale and read air consumption.

A 0.7 MPa, 7 bar (100 psi) air pressure

B 0.49 MPa, 4.9 bar (70 psi) air pressure

C 0.28 MPa, 2.8 bar (40 psi) air pressure