Clearances – Goodman Mfg ANSI Z21.47CSA-2.3 User Manual

Page 6

6

LIFT OVER APPROXIMATE

CENTER OF UNIT

SPREADER BARS

MUST BE USED WITH

LIFTING STRAPS THAT

ARE LESS THAN 16

FEET LONG

REMOVE 2 BRACKETS

ON EACH END TO

REMOVE

WOODEN STRUTS

REMOVE 2 BRACKETS

ON EACH END TO

REMOVE

SHIPPING BRACE

3. Lift unit per the “Rigging Details” section of this manual,

observing all warnings and cautions. When unit is

lifted, boards and shipping brace will drop if screws

have been removed. To avoid injury, STAND CLEAR.

4. Dispose of the boards and brace appropriately.

Curb installations must comply with local codes and should

be done in accordance with the established guidelines of the

National Roofing Contractors Association.

Proper unit installation requires that the roof curb be firmly

and permanently attached to the roof structure. Check for

adequate fastening method prior to setting the unit on the

curb.

Full perimeter roof curbs are available from the factory and

are shipped unassembled. Field assembly, squaring, level-

ing and mounting on the roof structure are the responsibility

of the installing contractor. All required hardware necessary

for the assembly of the sheet metal curb is included in the

curb accessory.

T

O

PREVENT

POSSIBLE

EQUIPMENT

DAMAGE

,

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

,

THE

FOLLOWING

BULLET

POINTS

MUST

BE

OBSERVED

WHEN

INSTALLING

THE

UNIT

.

WARNING

•

Sufficient structural support must be determined prior

to locating and mounting the curb and package unit.

•

Ductwork must be constructed using industry

guidelines. The duct work must be placed into the

roof curb before mounting the package unit. Our full

perimeter curbs include duct connection frames to be

assembled with the curb. Cantilevered type curbs

are not available from the factory.

•

Curb insulation, cant strips, flashing and general

roofing material are furnished by the contractor.

The curbs must be supported on parallel sides by roof mem-

bers. The roof members must not penetrate supply and re-

turn duct opening areas as damage to the unit might occur.

NOTE: The unit and curb accessories are designed to allow

vertical duct installation before unit placement. Duct

installation after unit placement is not recommended.

A

LL

CURBS

LOOK

SIMILAR

. T

O

AVOID

INCORRECT

CURB

POSITIONING

,

CHECK

JOB

PLANS

CAREFULLY

AND

VERIFY

MARKINGS

ON

CURB

ASSEMBLY

. I

NSTRUCTIONS

MAY

VARY

IN

CURB

STYLES

AND

SUPERCEDE

INFORMATION

SHOWN

.

CAUTION

See the manual shipped with the roof curb for assembly and

installation instructions.

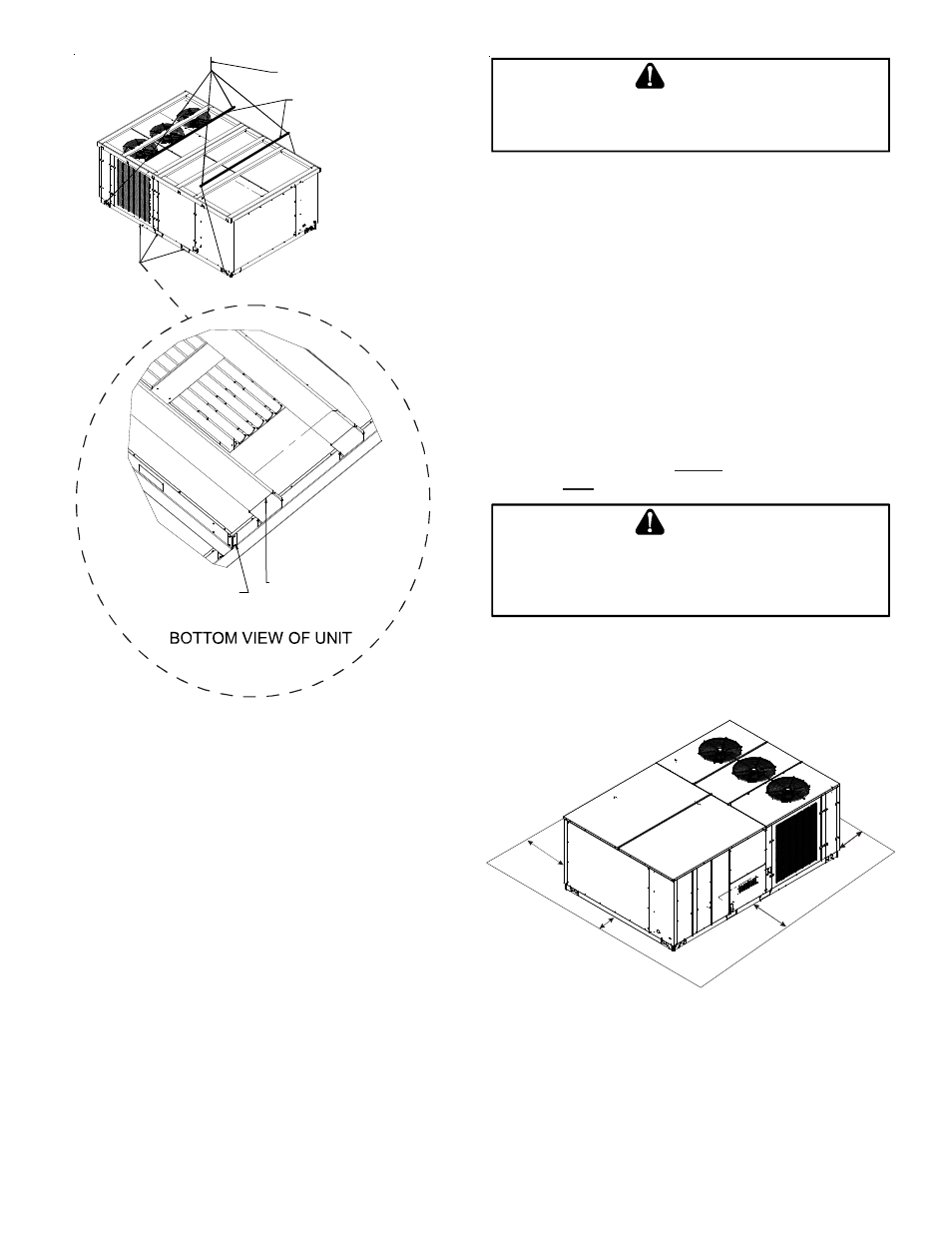

CLEARANCES

6”

72”

72”

72”

48”

48”

48”

48”

36”; minimum

roof overhang

UNIT CLEARANCES

Adequate clearance around the unit should be kept for safety,

service, maintenance, and proper unit operation. A total clear-

ance of 75” on the main control panel side of the unit is rec-

ommended to facilitate possible fan shaft, coil, electric heat

and gas furnace removal. A clearance of 48” is recommended

on all other sides of the unit to facilitate possible compressor