Goodman Mfg ANSI Z21.47CSA-2.3 User Manual

Page 21

21

Open Thermal Protection Device

If the primary limit switch opens, the gas valve is immediately

deenergized, the induced draft and air circulating blowers

are energized. The induced draft and air circulator blowers

remain energized until the limit switch recloses. The diag-

nostic fault code for an open limit is four (4) flashes.

A primary limit will open due to excessive supply air tempera-

tures. This can be caused by a dirty filter, excessive duct

static, insufficient air flow, or a faulty limit. Check filters, total

external duct static, blower motor, blower motor speed tap

(see wiring diagram), and limit. This limit will automatically

reset once the temperature falls below a preset level.

Flame Detected with Gas Valve Closed

If flame is detected with the gas valve deenergized, the com-

bustion and air circulator blowers are energized. The diag-

nostic fault code is five (5) flashes for this condition. The

control can be reset by removing the power supply to the unit

or it will automatically reset after one hour. Miswiring is the

probable cause for this fault.

A

BNORMAL

O

PERATION

- C

OOLING

Short Cycle Compressor Delay

The automatic ignition control has a built-in feature that pre-

vents damage to the compressor in short cycling situations.

In the event of intermittent power losses or intermittent ther-

mostat operation, the ignition control will delay output to the

compressor contactor for three minutes from the time power

is restored. (Compressor is off a total of three minutes). The

diagnostic LED will flash six (6) times to indicate the com-

pressor contactor output is being delayed.

NOTE: Some electronic thermostats also have a built-in

compressor short cycle timer that may be longer than the

three minute delay given above. If you are using an electronic

thermostat and the compressor has not started after three

minutes, wait an additional five minutes to allow the thermostat

to complete its short cycle delay time.

INPUT RATING

It is the responsibility of the contractor to adjust the gas input

to the unit. The input rate can be calculated by using the

formula:

I

NPUT Btu/Hr =

3600 x HV

T

WHERE:

HV = Heating value of fuel = Btu/ft of gas

T = Time in seconds per ft of gas flow as read from gas meter

3

3

Adjust input rate by varying the adjustment of the gas pres-

sure regulator on the gas valve. All adjustments must be made

with furnace operating at high fire and at normal operating

temperature. Clockwise (P) rotation of the pressure regula-

tor screw increases pressure and gas flow rate. Turn screw

counterclockwise (Q) to decrease pressure and gas flow rate.

After adjustment the furnace temperature rise must be within

the range specified on the unit data plate. NOTE: Thermal

efficiency of the furnace is a product efficiency rating deter-

mined under continuous operating conditions independent

of any installed system.

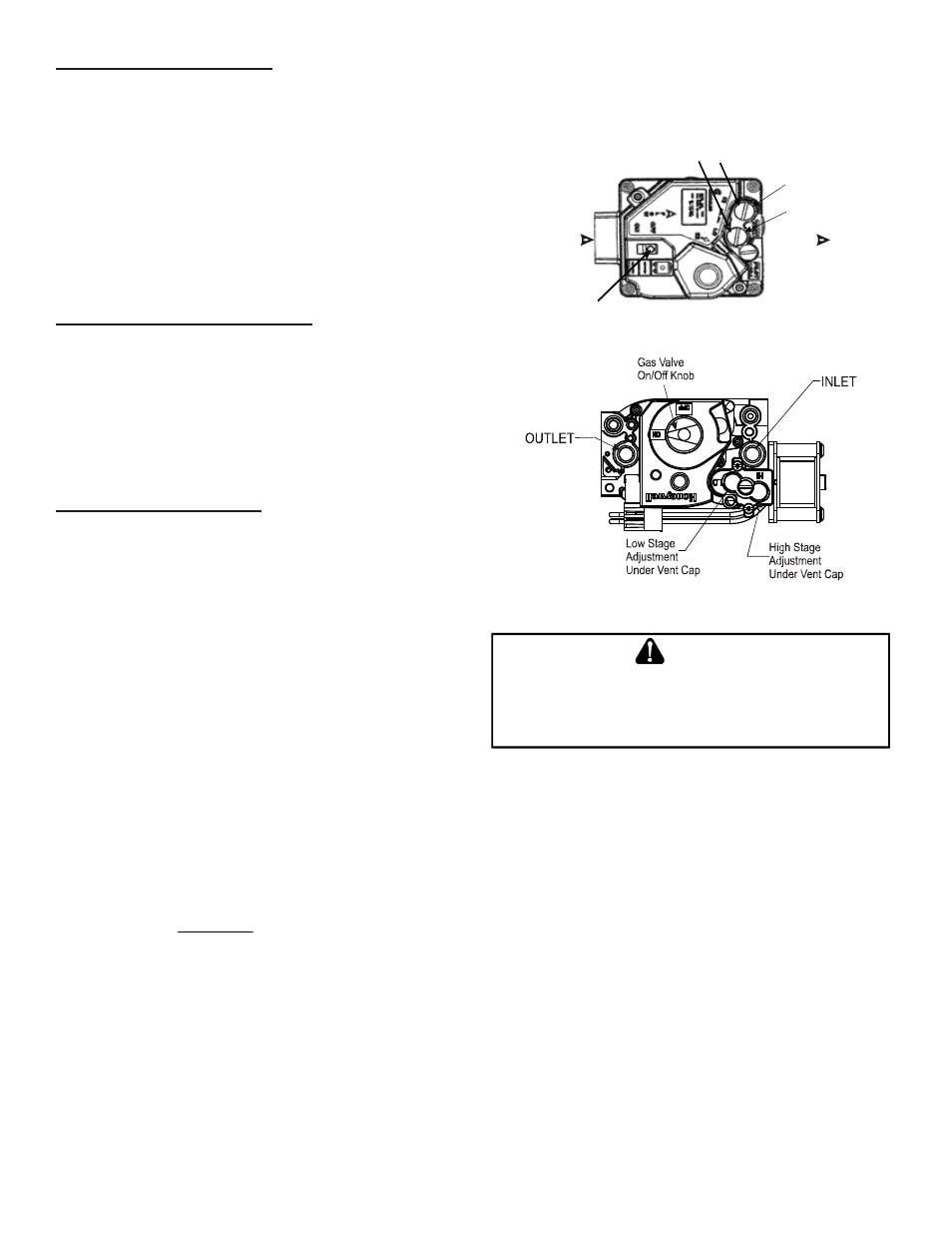

INLET

OUTLET

Gas Valve

On/Off Switch

Regulator Cover Screws

(Reg. Adj. Beneath these screws)

High Fire

Adjust

Low Fire

Adjust

WHITE-RODGERS 36H54 PRESSURE ADJUSTMENTS

HONEYWELL 0151M00015 PRESSURE ADJUSTMENTS

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

GAS

MANIFOLD

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

. O

NLY

MINOR

ADJUSTMENTS

SHOULD

BE

MADE

BY

ADJUSTING

THE

GAS

VALVE

PRESSURE

REGULATOR

.

CAUTION

AIR FLOW ADJUSTMENTS

The drive on the supply fan is typically set in the middle of the

RPM range. The drive motor sheave pitch diameter is field

adjustable for the required airflow. Refer to “Drive

Adjustments” section below.

When the final adjustments are complete, the current draw

of the motor should be checked and compared to the full

load current rating of the motor. The amperage must not ex-

ceed the service factor stamped on the motor nameplate.

The total airflow must not be less than that required for op-

eration of the electric heaters or the furnace.

If an economizer is installed, check the unit operating bal-

ance with the economizer at full outside air and at minimum

outside air. Upon completion of the air flow balancing, we

recommend replacing the variable pitched motor sheave with

a properly-sized fixed sheave. A matching fixed sheave will

provide longer belt and bearing life and vibration free opera-

tion. Initially, it is best to have a variable pitched motor sheave