Goodman Mfg ANSI Z21.47CSA-2.3 User Manual

Page 13

13

NOTE: The gas connection size at the unit does NOT

establish the size of the supply line.

3. These units are designed for either natural or propane

(LP) gas and are specifically constructed at the factory

for only one of these fuels. The fuels are NOT

interchangeable. However, the furnace can be

converted in the field from natural gas to LP gas with

the appropriate factory kit (see unit Technical Manual

for the appropriate kit). Only a qualified contractor,

experienced with natural and propane gas systems,

should attempt conversion. Kit instructions must be

followed closely to assure safe and reliable unit

operation.

4. With all units on a common line operating under full

fire, natural gas main supply pressure should be

adjusted to approximately 7.0" w.c., measured at the

unit gas valve. If the gas pressure at the unit is greater

than 10.5" w.c., the contractor must furnish and install

an external type positive shutoff service pressure

regulator. The unit will not function satisfactorily if

supply gas pressure is less than 5.5" w.c. or greater

than 10.5" w.c..

NOTE: A minimum horizontal distance of 48"

between the regulator and the furnace flue discharge

is required.

5. With all units on a common line operating under full

LP gas main supply pressure should be at least 11.0"

w.c. and must be no greater than 14.0" w.c., measured

at the unit gas valve. Unit will not function satisfactorily

if supply gas pressure is less than 11.0" w.c. or greater

than 14.0" w.c..

6. All pipe connections should be sealed with a pipe

thread compound, which is resistant to the fuel used

with the furnace. A soapy water solution should be

used to check all joints for leaks. A 1/8" NPT plugged

tap is located on the entering side of the gas valve for

test gauge connection to measure supply (main) gas

pressure. Another 1/8" tap is provided on the side of

the manifold for checking manifold pressure.

T

HIS

UNIT

AND

ITS

INDIVIDUAL

SHUTOFF

VALVE

MUST

BE

DISCONNECTED

FROM

THE

GAS

SUPPLY

SYSTEM

DURING

ANY

PRESSURE

TESTING

OF

THAT

SYSTEM

AT

TEST

PRESSURES

IN

EXCESS

OF

1/2 PSIG (13.8”

W

.

C

.).

WARNING

T

HIS

UNIT

MUST

BE

ISOLATED

FROM

THE

GAS

SUPPLY

PIPING

SYSTEM

BY

CLOSING

ITS

INDIVIDUAL

MANUAL

SHUTOFF

VALVE

DURING

ANY

PRESSURE

TESTING

EQUAL

TO

OR

LESS

THAN

1/2 PSIG.

CAUTION

7. There must be no obstruction to prevent the flow of

combustion and ventilating air. A vent stack is not

required and must never be used. The power ventor

will supply an adequate amount of combustion air as

long as the air passageways are kept free of any

obstructions and the recommended external unit

clearances are maintained.

CIRCULATING AIR AND FILTERS

D

UCTWORK

The supply duct should be provided with an access panel

large enough to inspect the air chamber downstream of the

heat exchanger. A cover should be tightly attached to pre-

vent air leaks.

Ductwork dimensions are shown in the roof curb installation

manual.

If desired, supply and return duct connections to the unit may

be made with flexible connections to reduce possible unit

operating sound transmission.

VENTING

NOTE: Venting is self-contained.

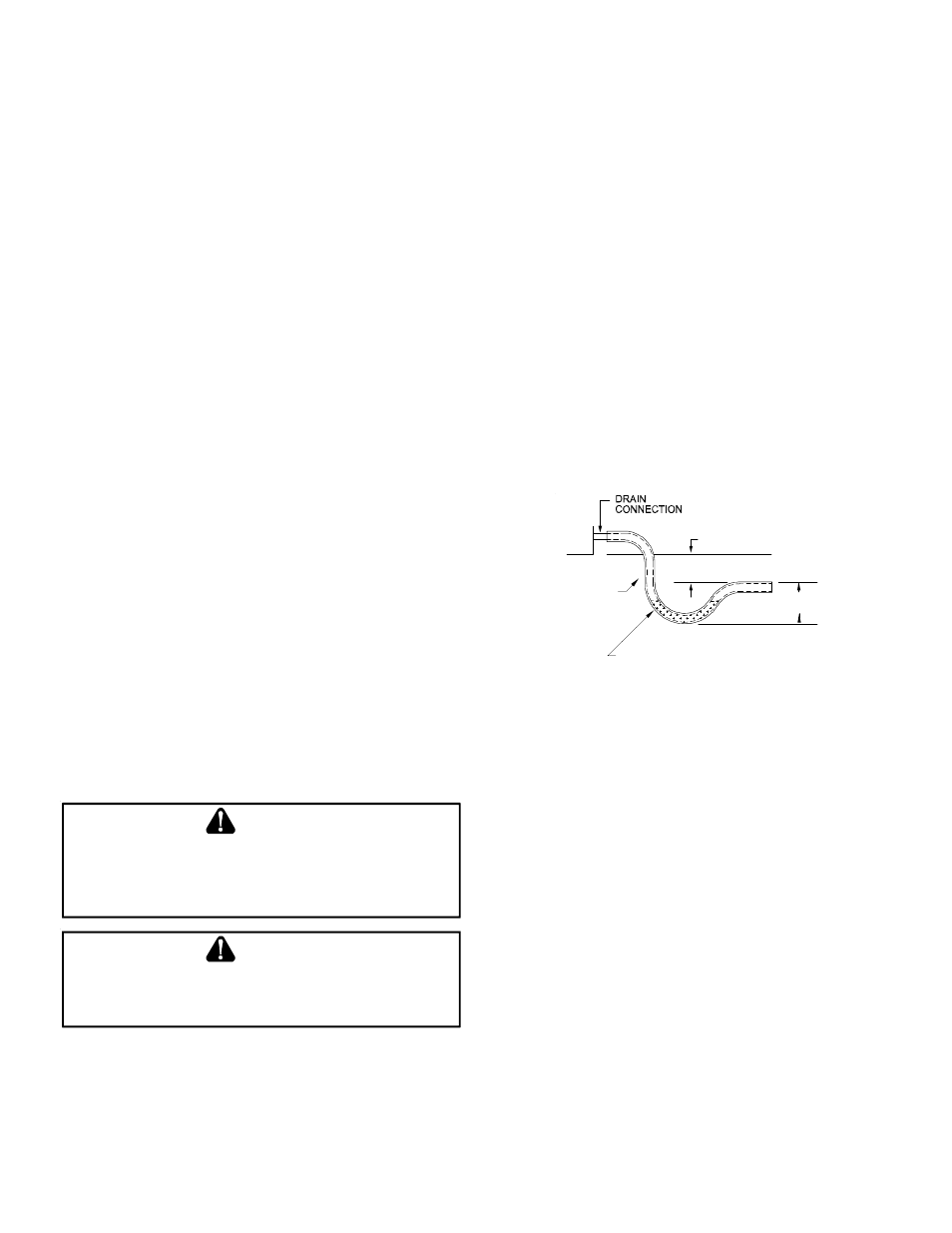

CONDENSATE DRAIN CONNECTION

C

ONDENSATE

D

RAIN

C

ONNECTION

A 3/4” NPT drain connection is supplied for condensate pip-

ing. An external trap must be installed for proper condensate

drainage.

UNIT

2" MINIMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

3" MINIMUM

A POSITIVE LIQUID

SEAL IS REQUIRED

DRAIN CONNECTION

Install condensate drain trap as shown. Use 3/4" drain line

and fittings or larger. Do not operate without trap.

H

ORIZONTAL

D

RAIN

Drainage of condensate directly onto the roof may be ac-

ceptable; refer to local code. It is recommended that a small

drip pad of either stone, mortar, wood or metal be provided to

prevent any possible damage to the roof.

C

LEANING

Due to the fact that drain pans in any air conditioning unit

will have some moisture in them, algae and fungus will

grow due to airborne bacteria and spores. Periodic clean-

ing is necessary to prevent this build-up from plugging the

drain.