Making a cut, Making a plunge cut – Global Machinery Company TTS5000M User Manual

Page 14

14

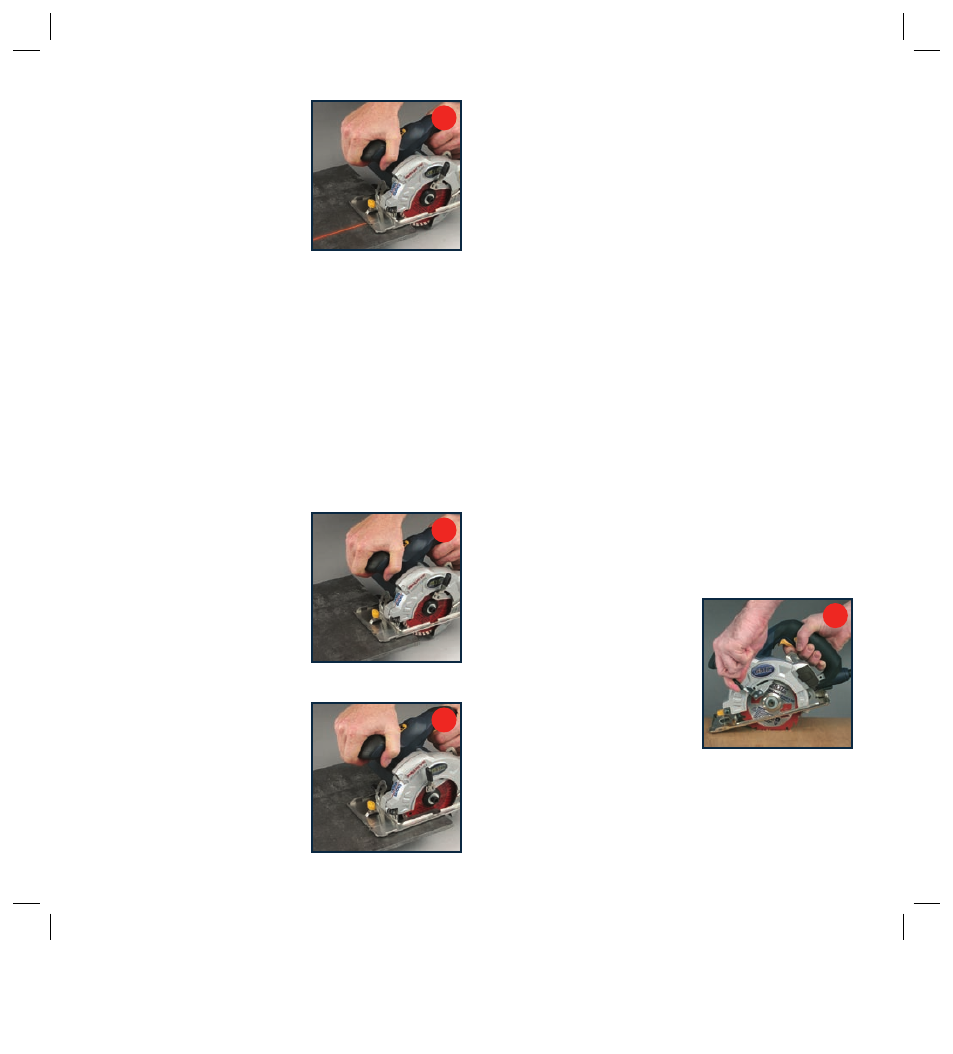

4. Switch on the laser beam

using the laser light on/off

button (4) (Fig. U).

5. Align the beam with the line on

the workpiece (Fig. V).

6. Start the motor by pressing

the lock off button (3) and

squeezing the trigger switch (2).

7. Always let the blade reach full

speed (approximately

2 seconds) before you begin to cut into the workpiece.

8. Slowly push the saw forward using both hands, keeping

the red laser light beam on the line of cut.

9. After completing your cut, release the trigger switch

and allow the blade to come to a complete stop.

Do not remove the saw from the work piece while

the blade is moving.

10. Switch off the laser beam on completion of the cut.

Making a cut

1. Mark the line of cut on the

workpiece.

2. Adjust the depth of cut and

bevel angle as required.

3. Rest the front edge of the

base plate (12) on the

workpiece. Make sure that

there is no contact between

the blade and the workpiece

(Fig. W).

4. Start the motor by pressing

the lock off button (3) and

squeezing the trigger

switch (2).

Note.

Always let the blade reach

full speed (approximately

2 seconds) before you begin to

cut into the workpiece.

5. Slowly push the saw forward using both hands (Fig. X).

6. When making a cut always use steady, even pressure.

Forcing the saw causes rough cuts and could shorten the

life of the saw or cause kickback. Allow the blade and the

saw to do the work.

7. After completing your cut, release the trigger switch and

allow the blade to come to a complete stop.

Do not remove the saw from the workpiece while the

blade is moving.

Note.

To prevent possible overload of the motor, the depth

of cut should not be more than 20mm at a pass. When you

wish to cut deeper than 20mm make a number of passes

with progressively deeper settings.

Note.

As a general rule, align the outer blade guide notch

(19b) on the front of the base plate with the cut line when

making bevel cuts. For more accuracy, it may be necessary

to make a trial cut in a scrap piece of material along a

guideline to determine how much you should offset the

blade from the guideline. At the same time, you can also

check the angle of cut if this is critical. The outer blade

guide notch (19a) should be aligned with the cutting line

when making straight cuts.

Making a plunge cut

1. Adjust the depth of cut as

required.

2. Adjust the bevel setting to 0°.

3. Use the blade guard lever (23)

to raise the lower blade guard

(22) and expose the saw

blade (Fig. Y).

4. Firmly rest the front of the

base plate (12) flat against the

workpiece with the rear handle

raised, so the blade does not touch the workpiece.

5. With the blade just clearing the workpiece, start the motor

by pressing the lock off button (3) and squeezing the

trigger switch (2).

V

Y

w

X