Installation – Graco 230-998 User Manual

Page 6

6

307–636

Installation

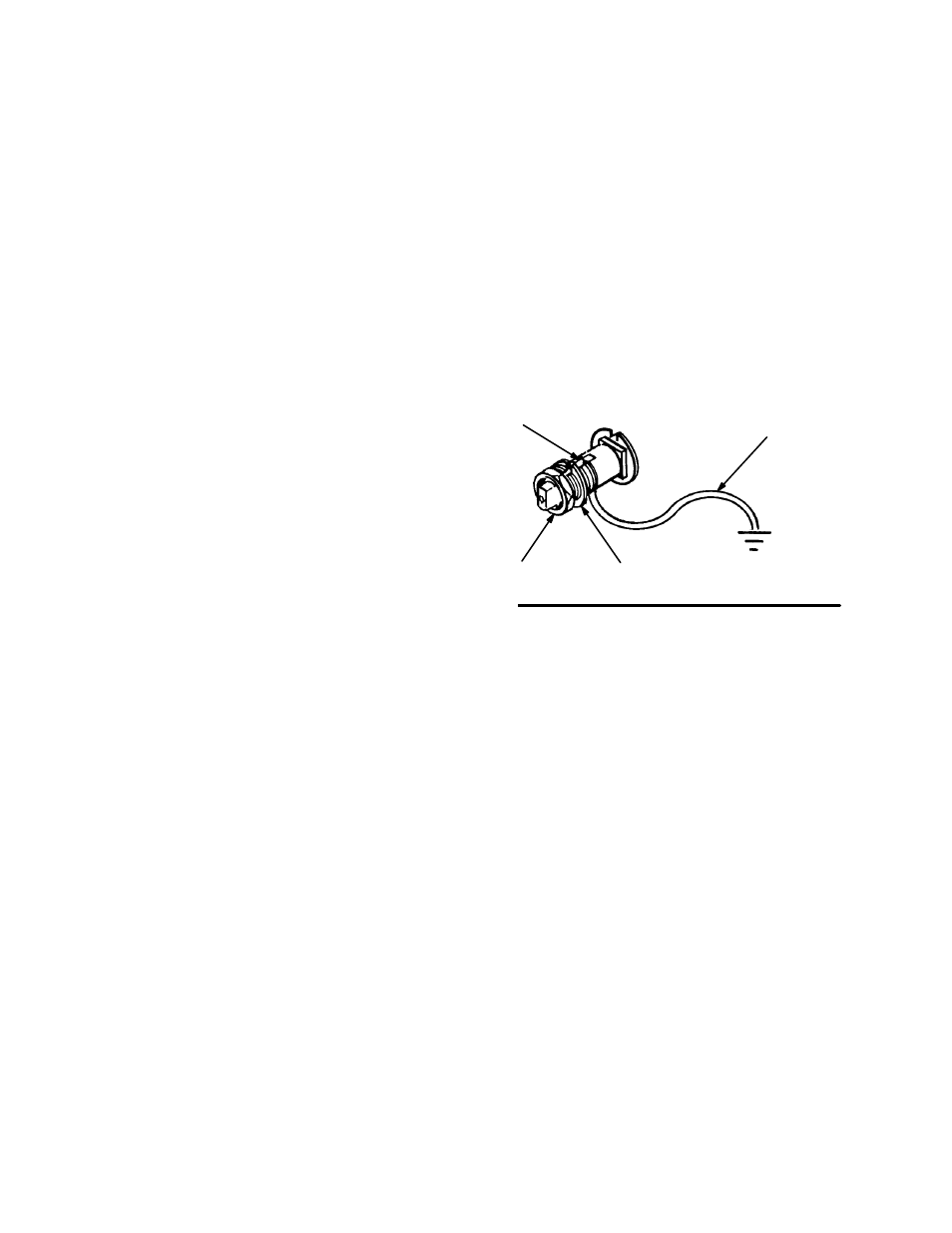

Grounding

To reduce the risk of static sparking, ground the pump,

object being sprayed, and all other spray/dispensing

equipment used or located in the spray/dispensing

area. Check you local electrical code for detailed

grounding instructions for your area and type of equip-

ment. Be sure to ground all of this spray/dispensing

equipment:

1.

Pump: loosen the grounding lug locknut (W) and

washer (X). Insert one end of a 1.5 mm

2

(12 ga)

minimum ground wire (Y) into the slot in lug (Z)

and tighten the locknut securely. See Fig. 1.

Connect the other end of the wire to a true earth

ground. Order Part No. 237–569, Ground Wire and

Clamp.

2.

Air compressor: follow manufacturer’s recommen-

dations.

3.

Air and fluid hoses: use only grounded hoses with

a maximum of 500 ft (150 m) combined hose

length to ensure grounding continuity.

4.

Spray gun: grounding is obtained through connec-

tion to a properly grounded fluid hose and pump.

5.

Object being sprayed: according to your local

code.

6.

Fluid supply container: according to your local

code.

7.

All solvent pails used when flushing, according to

local code. Use only metal pails, which are con-

ductive, placed on a grounded surface. Do not

place the pail on a nonconductive surface, such as

paper or cardboard, which interrupts the grounding

continuity.

8.

To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

spray gun firmly to the side of a grounded metal

pail, then trigger the spray gun.

Fig. 1

W

X

Y

Z