Grinder installation – Grizzly G8183 User Manual

Page 2

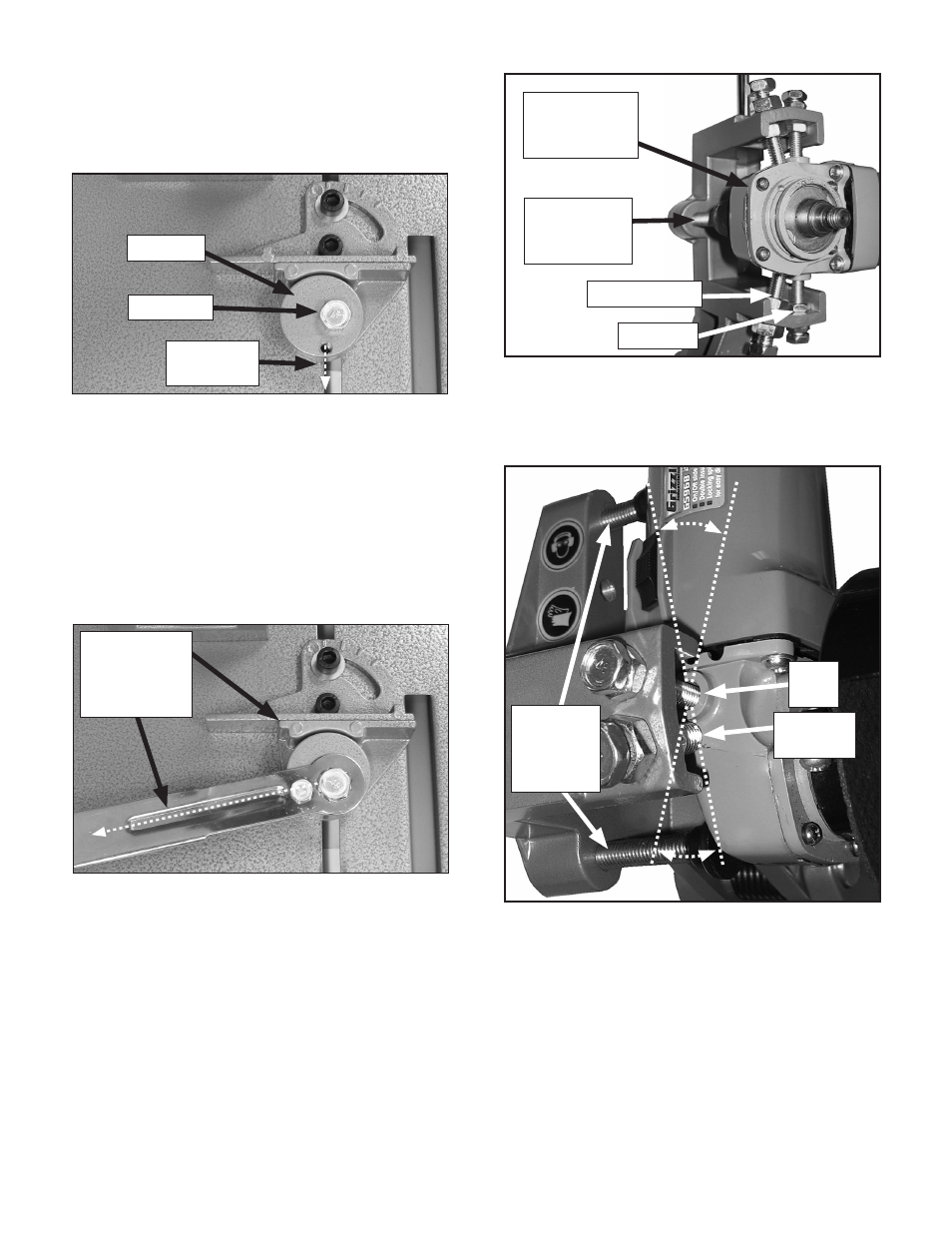

Figure 5. G8183 grinder mounting locations.

3. Finger tighten both stabilizer bolts against the

grinder headstock casting (

Figure 5).

Figure 6. G8183 grinder alignment.

2. remove the lever on the eccentric, loosen

the t-nut bolt so it is just finger tight, then

rotate the cam so the threaded hole is at the

6 o'clock position as shown in

Figure 3.

Figure 3. G8183 quick lock vise.

3. reinstall the lever, and move it to the left so

the cam tightens and both vise jaws clamp

together (

Figure 3).

—If the lever does not clamp the vise jaws

together firmly and stop approximately at

the 8 o'clock position (

Figure 4), repeat

Step 2.

4. Adjust the grinder blade guard so when

the cut will be made, the guard is tilted for

maximum user protection from sparks. refer

to your grinder owner's manual for guard

positioning and spark safety requirements.

5. Alternately thread both of the rubber-foot

alignment studs against the grinder body to

pivot the grinder into alignment for straight

cuts (

Figure 6).

6 o'clock

position

t-Nut Bolt

Grinder Installation

1. position the grinder so the abrasive blade

will enter the slot in the base after the cut is

made.

2. thread both pivot bolts completely into the

holes in the grinder headstock and tighten

the jam nuts (

Figure 5). Note: The hole may

be larger in diameter than the pivot bolts

because these pivot bolts merely serve as

the pivot pins for when the grinder is adjusted

in

Step 5.

Figure 4. G8183 quick lock vise lever.

Vise Locked

and Lever in

the 8 o'clock

position

pivot Bolt

Stabilizer Bolt

rubber Foot

Alignment

Stud

Grizzly Model

5968 Angle

Grinder

pivot

Bolt

rubber

Foot

Alignment

Stud

Eccentric

Stabilizer

Bolt