Mounting to shop floor checking gear oil test run, Mounting to shop floor, Notice – Grizzly G0554Z User Manual

Page 18: Test run, Checking gear oil

-16-

Model g0554z (Mfg 01/09+)

you can either bolt your machine to the floor or

use the included foot pads and leveling hard-

ware. Because mounting your lathe to the floor

with permanent hardware is an optional step and

floor materials may vary, floor mounting hardware

is not included. Whichever option you choose,

it is necessary to first level your machine with a

precision level to prevent cracking or warping of

the cast iron bed and ways, as described on the

previous page.

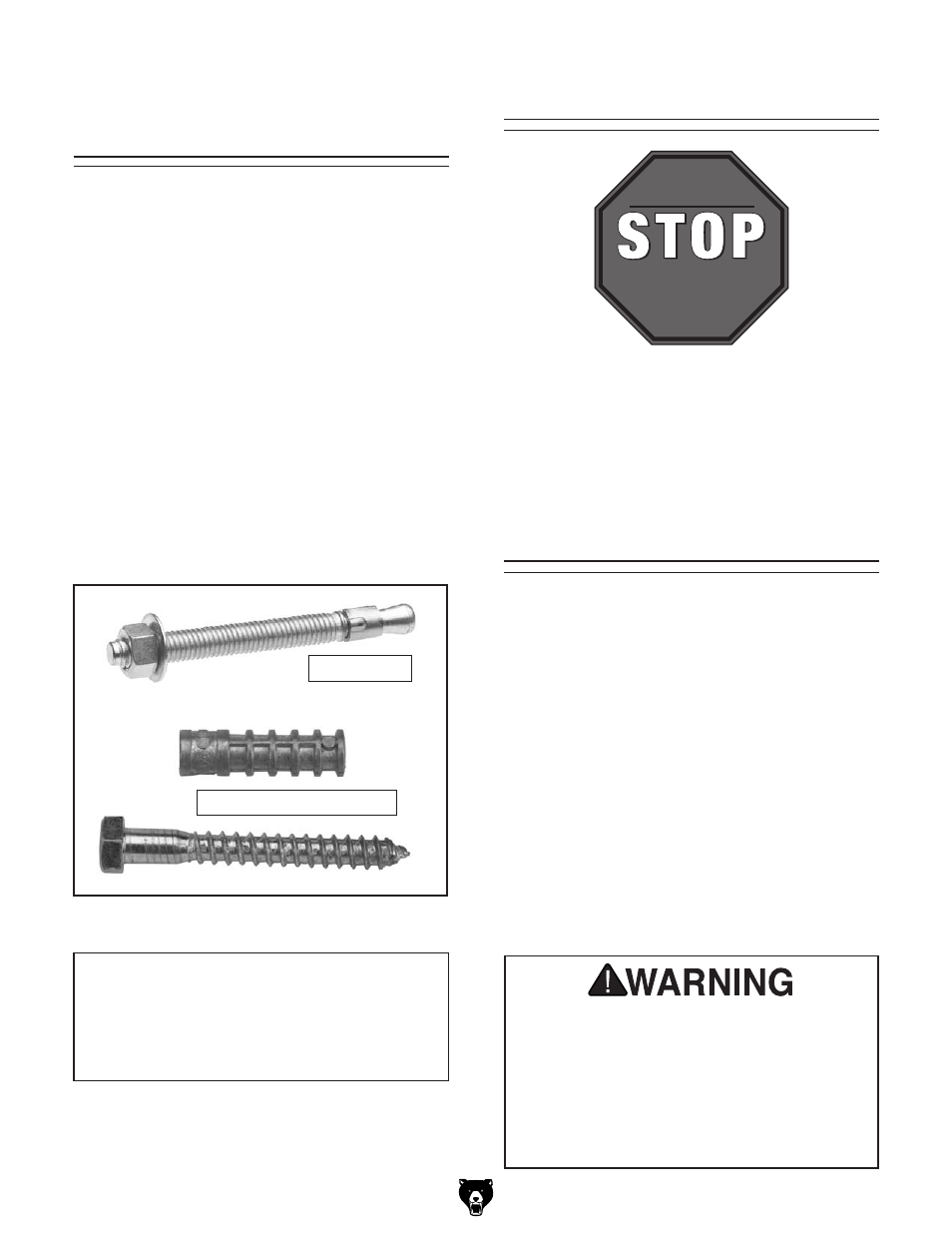

bolting to concrete Floors

Anchor studs and lag shield anchors with lag bolts

(

Figure 12) are two popular methods for anchor-

ing an object to a concrete floor. We suggest

you research the many options and methods for

mounting your machine and choose the best that

fits your specific application.

Mounting to Shop

Floor

Figure 12. typical fasteners for mounting to

concrete floors.

Anchor stud

lag shield Anchor & Bolt

NOTICE

We strongly recommend securing your

machine to the floor if it is hardwired to the

power source. consult with your electrician

to ensure compliance with local codes.

before starting the lathe, make sure you have

correctly performed the preceding setup

instructions, and you have read through the

rest of the manual and are familiar with the

various functions and safety features on

this machine. Failure to follow this warning

could result in serious personal injury or

even death!

Test Run

once the assembly is complete, test run your

machine to make sure it runs properly and is

ready for regular operation. the test run consists

of verifying the following: 1) the motor powers up

and runs correctly, 2) the stop button safety fea-

ture works correctly, 3) the coolant system oper-

ates correctly, 4) the foot brake works correctly,

and 5) the left side door safety switch works cor-

rectly.

if, during the test run, you cannot easily locate

the source of an unusual noise or vibration, stop

using the machine immediately, then review

Troubleshooting on page 48.

if you cannot find a remedy, contact our tech

support at (570) 546-9663 for assistance.

GEARBOXES MUST

BE FILLED WITH OIL!

MACHINE MAY NOT BE

SHIPPED WITH OIL!

Requires Oil

Before Operation

or Warranty Will

Be Void.

checking Gear Oil

you must make sure the headstock, gearbox, and

apron oil reservoirs have oil in them before run-

ning the lathe for the first time to ensure the gears

are not damaged. refer to the

Lubrication sec-

tion on

page 52 for detailed instructions.