Caution, Warning – Goodman Mfg GPG13 User Manual

Page 7

7

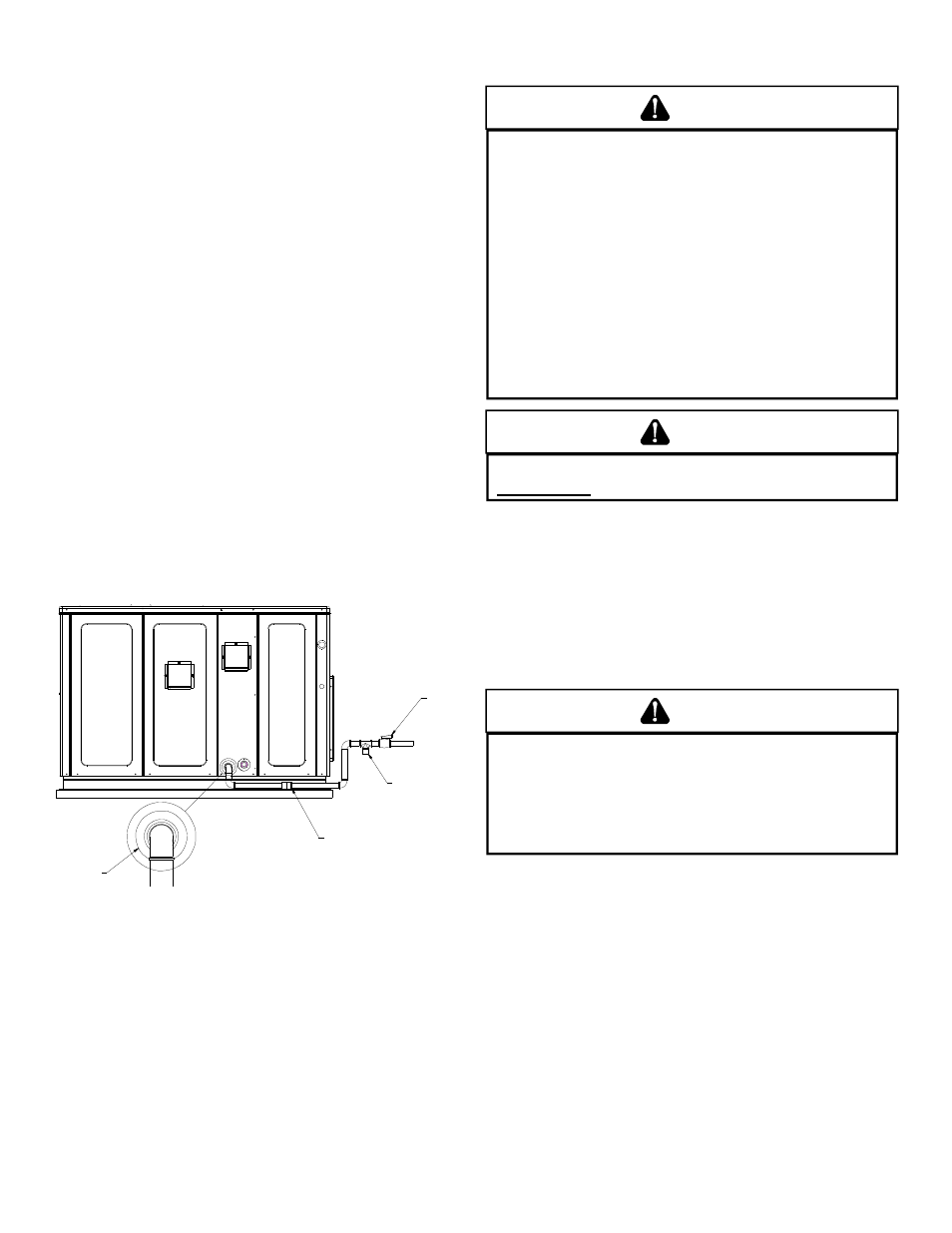

Refer to the Proper Piping Practice drawing for the general layout

at the unit. The following rules apply:

1. Use black iron pipe and fittings for the supply piping. The

use of a flex connector and/or copper piping is permitted

as long as it is in agreement with local codes.

2. Use pipe joint compound on male threads only. Pipe joint

compound must be resistant to the action of the fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can enter

the gas valve. The drip leg must be a minimum of three

inches long.

5. Use two pipe wrenches when making connection to the gas

valve to keep it from turning.

6. Install a manual shut-off valve in a convenient location

(within six feet of unit) between the meter and the unit.

7. Tighten all joints securely.

8. The unit must be connected to the building piping by one

of the following methods:

•

Rigid metallic pipe and fittings

•

Semirigid metallic tubing and metallic fittings (Aluminum

alloy tubing must not be used in exterior locations)

•

Listed gas appliance connectors used in accordance with

the terms of their listing that are completely in the same

room as the equipment

•

In the prior two methods above the connector or tubing

must be protected from physical and thermal damage.

Aluminum alloy tubing and connectors must be coated to

protect against external corrosion when in contact with

masonry, plaster or insulation or are subject to repeated

wettings by liquids (water - not rain water, detergents or

sewage)

DRIP LEG

MANUAL

SHUT-OFF

VALVE

GROUND JOINT UNION

(INSTALLED AHEAD OF GAS VALVE)

GROMMET

Proper Piping Practice

NOTE: The unit gas supply entrance is factory sealed with plugs.

Keep plugs in place until gas supply is ready to be installed. Once

ready, replace the plugs with the supplied grommets and install gas

supply line.

G

AS

P

IPING

C

HECKS

CAUTION

T

O PREVENT PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, THE

FOLLOWING INSTRUCTIONS MUST BE PERFORMED REGARDING GAS

CONNECTIONS AND PRESSURE TESTING:

•

T

HE UNIT AND ITS GAS CONNECTIONS MUST BE LEAK TESTED BEFORE

PLACING IN OPERATION.

B

ECAUSE OF THE DANGER OF EXPLOSION OR

FIRE, NEVER USE A MATCH OR OPEN FLAME TO TEST FOR LEAKS.

N

EVER

EXCEED SPECIFIED PRESSURES FOR TESTING.

H

IGHER PRESSURE MAY

DAMAGE GAS VALVE AND CAUSE OVERFIRING WHICH MAY RESULT IN

PREMATURE HEAT EXCHANGE FAILURE.

•

T

HIS UNIT AND ITS SHUT-OFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY DURING ANY PRESSURE TESTING OF THAT SYSTEM AT

TEST PRESSURES IN EXCESS OF 1/2

PSIG

(3.48 K

P

A).

•

T

HIS UNIT MUST BE ISOLATED FROM THE GAS SUPPLY SYSTEM BY

CLOSING ITS MANUAL SHUT-OFF VALVE DURING ANY PRESSURE

TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES

EQUAL TO OR LESS THAN 1/2

PSIG

(3.48 K

P

A).

WARNING

T

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY

, BE SURE THERE IS

NO OPEN FLAME IN THE VICINITY DURING AIR BLEEDING.

There will be air in the gas supply line after testing for leaks

on a new installation. Therefore, the air must be bled from the

line by loosening the ground joint union until pure gas is

expelled. Tighten union and wait for five minutes until all gas

has been dissipated in the air. Be certain there is no open

flame in the vicinity during air bleeding procedure. The unit is

placed in operation by closing the main electrical disconnect

switch for the unit.

PROPANE GAS INSTALLATIONS

WARNING

T

O AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO FIRE

OR EXPLOSION CAUSED BY A PROPANE GAS LEAK, INSTALL A GAS

DETECTING WARNING DEVICE.

S

INCE RUST CAN REDUCE THE LEVEL

OF ODORANT IN PROPANE GAS, A GAS DETECTING WARNING DEVICE

IS THE ONLY RELIABLE WAY TO DETECT A PROPANE GAS LEAK.

C

ONTACT A LOCAL PROPANE GAS SUPPLIER ABOUT INSTALLING A

GAS DETECTING WARNING DEVICE.

IMPORTANT NOTE: Propane gas conversion kits must be

installed to convert units to propane gas.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters (See NBFU

Manual 58).

For satisfactory operation, propane gas supply pressure must

be within 9.7 - 10.3 inches W.C. at the manifold with all gas

appliances in operation. Maintaining proper gas pressure

depends on three main factors:

1. Vaporization rate, which depends on (a) temperature of the

liquid, and (b) wetted surface area of the container or

containers.

2. Proper pressure regulation.

3. Pressure drop in lines between regulators, and between

second stage regulator and the appliance. Pipe size

required will depend on length of pipe run and total load of

all appliances.