Warning – Goodman Mfg GPG13 User Manual

Page 14

14

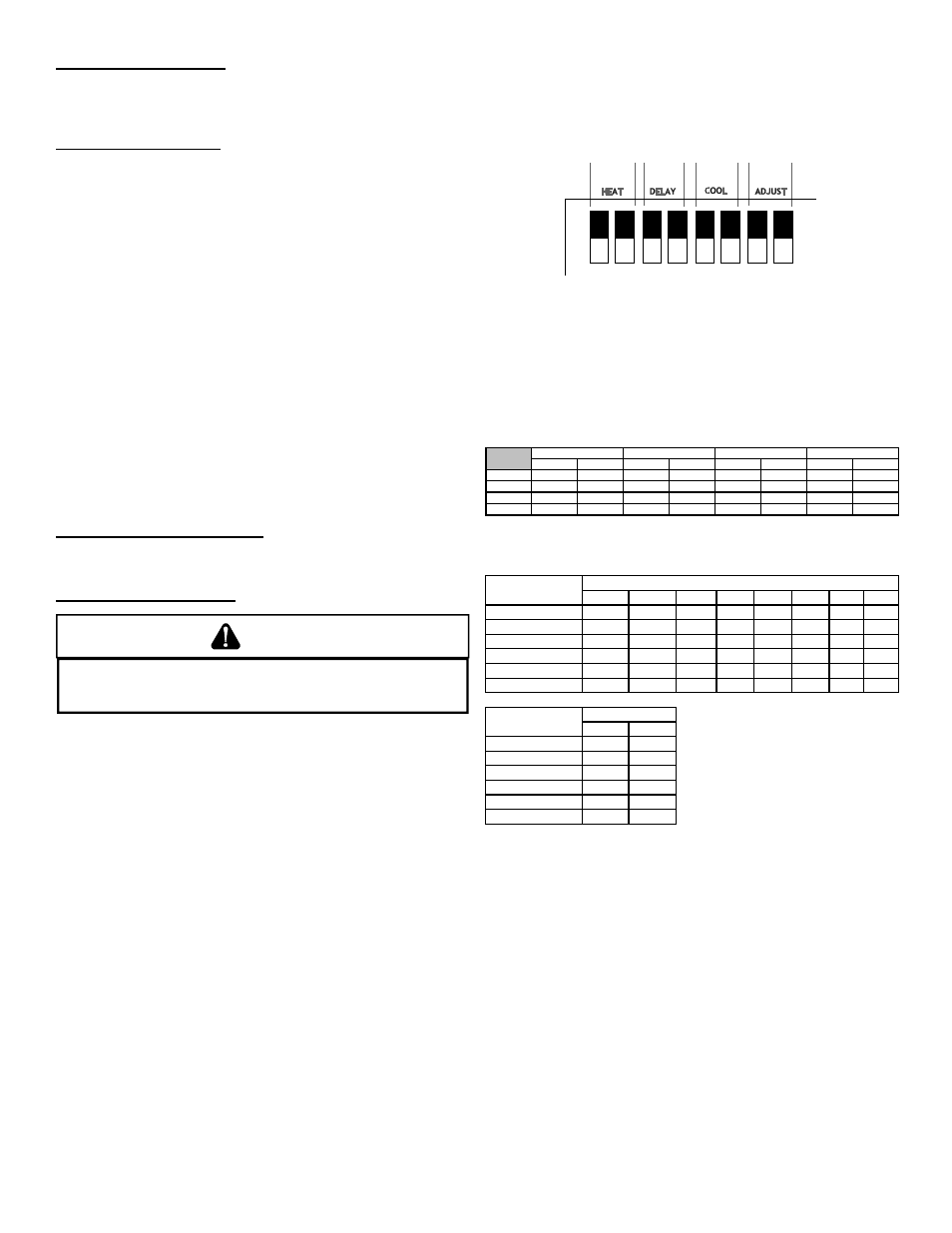

(switches 1 and 2) provides airflow adjustment for heating

airflow. The “COOL” adjustment function (switches 5 and 6)

provides airflow adjustments for cooling airflow. The

“ADJUST” function (switches 7 and 8) will adjust the heating

AND cooling airflow +10% or - 15%. The “DELAY” function

(switches 3 and 4) is not field adjustable.

O

N

To adjust the HEAT, COOL or ADJUST functions, simply change

the ON/OFF position of the appropriate dipswitches. The table

below shows the ON/OFF combinations for the various switches

and the corresponding A, B, C, or D taps. Refer to the Product

Data Book applicable to your model for airflow tables and

temperature rise. The “Dipswitch Position” table below shows

the factory dipswitch settings for each model. The “CFM” table

below shows the nominal heating and cooling CFM for each

model.

1

2

3

4

5

6

7

8

A

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

B

ON

OFF

ON

OFF

ON

OFF

ON

OFF

C

OFF

ON

OFF

ON

OFF

ON

OFF

ON

D

ON

ON

ON

ON

ON

ON

ON*

ON*

‡ Factory Set; not field adjustable

* Tap D has no effect on airflow

ADJUST

HEAT

DELAY‡

COOL

Dipswitch Settings and Corresponding Tap

1

2

3

4

5

6

7

8

GPG13480701*

ON

ON

OFF

OFF

ON

OFF

OFF

OFF

GPG13480901*

OFF

ON

OFF

OFF

ON

OFF

OFF

OFF

GPG13481151*

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

GPG13600901*

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

GPG13601151*

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

GPG13601401*

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

HEAT

COOL

GPG13480701*

1020

1540

GPG13480901*

1140

1540

GPG13481151*

1420

1540

GPG13600901*

1140

1810

GPG13601151*

1420

1810

GPG13601401*

1700

1810

Model

DIP SWITCH POSITION

Model

CFM

Unit dipswitches are factory set for each model, see label on

blower housing for CFM adjustment next to low voltage terminal

connections.

NOTE: Heating airflow must be adjusted to provide the tempera-

ture rise shown on rating plate.

*PG1360***1A ONLY: Low stage airflow is approximately 75%

of high stage cooling airflow. Example: High stage cooling

airflow is 1800 CFM. Low stage cooling airflow is 0.75*1800

CFM = 1350 CFM.

The adjustment factors for the ADJUST function are A = 1, B =

1.10 (+10%) and C = 0.85 (-15%). The D tap for the ADJUST

function has no effect on airflow. Example: Airflow tables

indicate 1425 CFM. With the ADJUST set to B tap, the CFM

becomes 1.10*1425 CFM = 1568 CFM.

Main Burner Flame Check

Flames should be stable, soft and blue (dust may cause

orange tips but they must not be yellow) and extending directly

outward from the burner without curling, floating or lifting off.

Temperature Rise Check

Check the temperature rise through the unit by placing

thermometers in supply and return air registers as close to the

unit as possible. Thermometers must not be able to sample

temperature directly from the unit heat exchangers, or false

readings could be obtained.

1. All registers must be open; all duct dampers must be in their

final (fully or partially open) position and the unit operated

for 15 minutes before taking readings.

2. The temperature rise must be within the range specified on

the rating plate.

NOTE: Air temperature rise is the temperature difference between

supply and return air.

With a properly designed system, the proper amount of

temperature rise will normally be obtained when the unit is

operated at rated input with the recommended blower speed.

If the correct amount of temperature rise is not obtained, it

may be necessary to change the blower speed. A higher blower

speed will lower the temperature rise. A slower blower speed

will increase the temperature rise.

NOTE: Blower speed MUST be set to give the correct air tempera-

ture rise through the unit as marked on the rating plate.

External Static Pressure Check

The total external static pressure must be checked on this

unit to determine if the airflow is proper.

Blower Speed Adjustments

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK, REMOVE

ELECTRICAL POWER FROM THE UNIT BEFORE CHANGING SPEED TAPS ON THE

BLOWER MOTOR.

Refer to the wiring diagram in the appendix to verify speed tap

settings.

Blower speeds are to be changed at the ignition control board.

Both heat speed and cool speed terminals are supplied on

the board along with two unused motor lead terminals.

*PG13(48, 60)***1B, 3A, 4A models are equipped with X-13

motors. X-13 motors are constant torque motors with very low

power consumption. This motor is energized by 24V. Adjust

the CFM for the unit by changing the 24V low voltage leads to

the speed terminal block on the motor.

Heating-White Lead

Cooling-Yellow Lead

T1 - Low Speed

T4 - Low Speed

T2 - Medium Speed

T5 - High Speed

T3 - High Speed

*PG13(48, 60)***1A models are equipped with GE ECM

motors. These motors offer greater airflow flexibility as well

as dehumidification. The airflow delivery for these models

can be adjusted by changing the position of dip switches on

a low voltage terminal board. The figure below shows the

dipswitch layout on the low voltage terminal board as well as

the function of each set of switches. The “HEAT” function