Adjusting depth – Grizzly H7947/H7948 User Manual

Page 12

H7947/H7948 16 Gauge Stapler

-10

-

Note: Deflection is caused when grain

irregularities, knots or foreign objects

inside the wood cause the staple

to change its path, resulting in the

staple puncturing the surface of the

workpiece.

Besides damaging your workpiece,

deflection can cause injury if your free

hand is securing the workpiece in the

location that the staple deflects.

5. Pull the trigger.

— If the staple penetrates the wood to

the depth you want, continue with

your intended operations.

— If the staple either went too far or not

far enough, adjust the depth of fire

by following the procedures listed on

Pages 10-11.

4. Before pulling the trigger, make sure

your free hand and other body parts

are positioned out of the way of a

potential path of a staple in case of

deflection (illustrated below in

Figure

6).

Figure 6. Example of staple deflection.

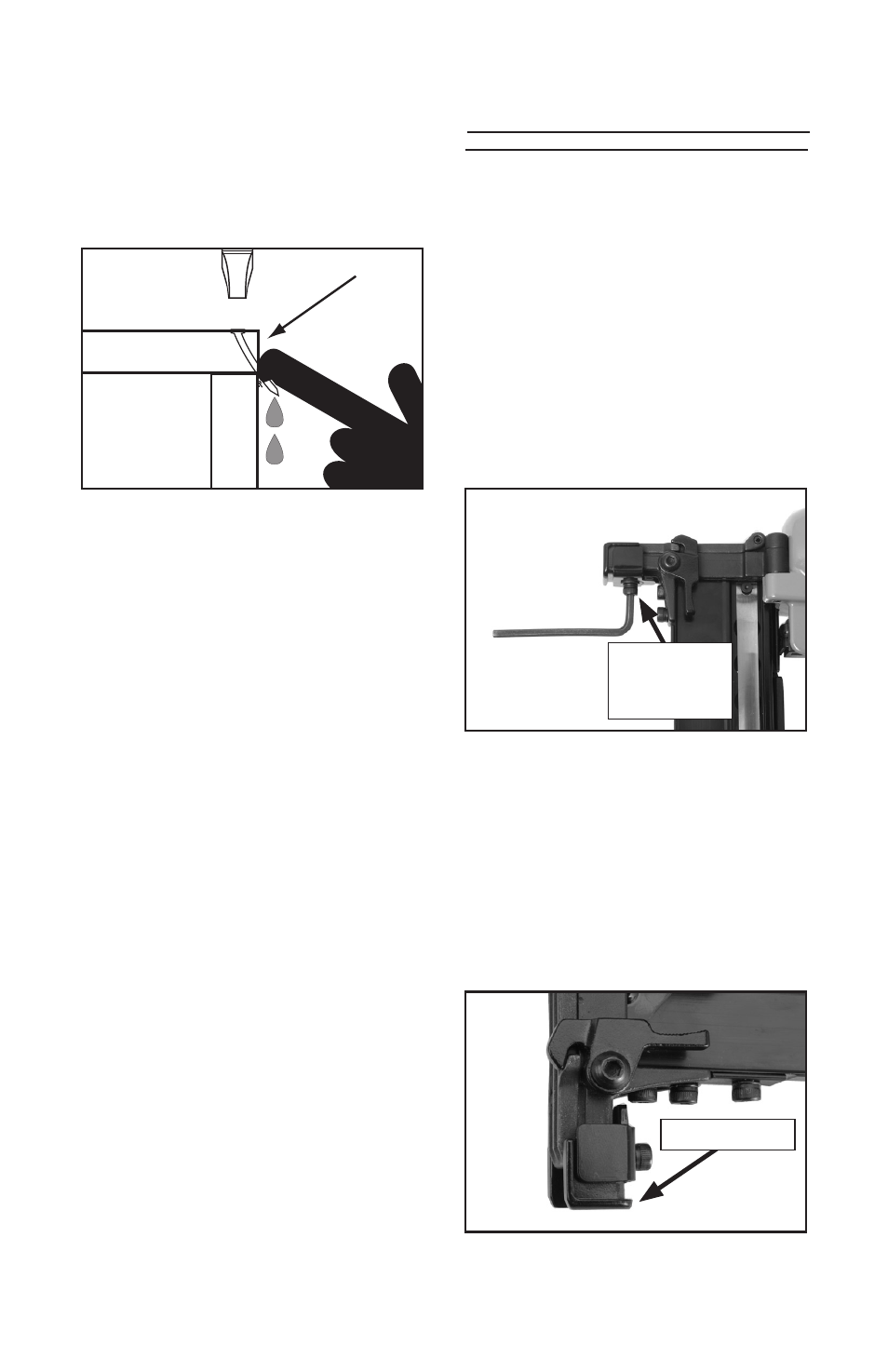

Figure 7. Depth adjustment cap screw.

Adjusting Depth

Changing the depth of staple penetration is

done by changing the position of the adjust-

ing block on the contact arm.

To adjust the depth:

1. DISCONNECT STAPLER FROM THE

AIR SUPPLY.

2. Use a 4mm hex wrench to loosen the

depth adjustment cap screw on the

contact arm as shown in

Figure 7.

3. Move the adjusting block (Figure 8) up

or down to increase or decrease staple

penetration.

— If you want to decrease the staple

depth, then move the adjusting

block down, away from the nose as

shown in

Figure 8.

Figure 8. Adjusting block down.

Adjusting Block

Depth

Adjustment

Cap Screw