Troubleshooting, Symptom possible cause solution – Grizzly Airbrush Kit G5354 User Manual

Page 12

Model G5354 Airbrush

-12

-

Troubleshooting

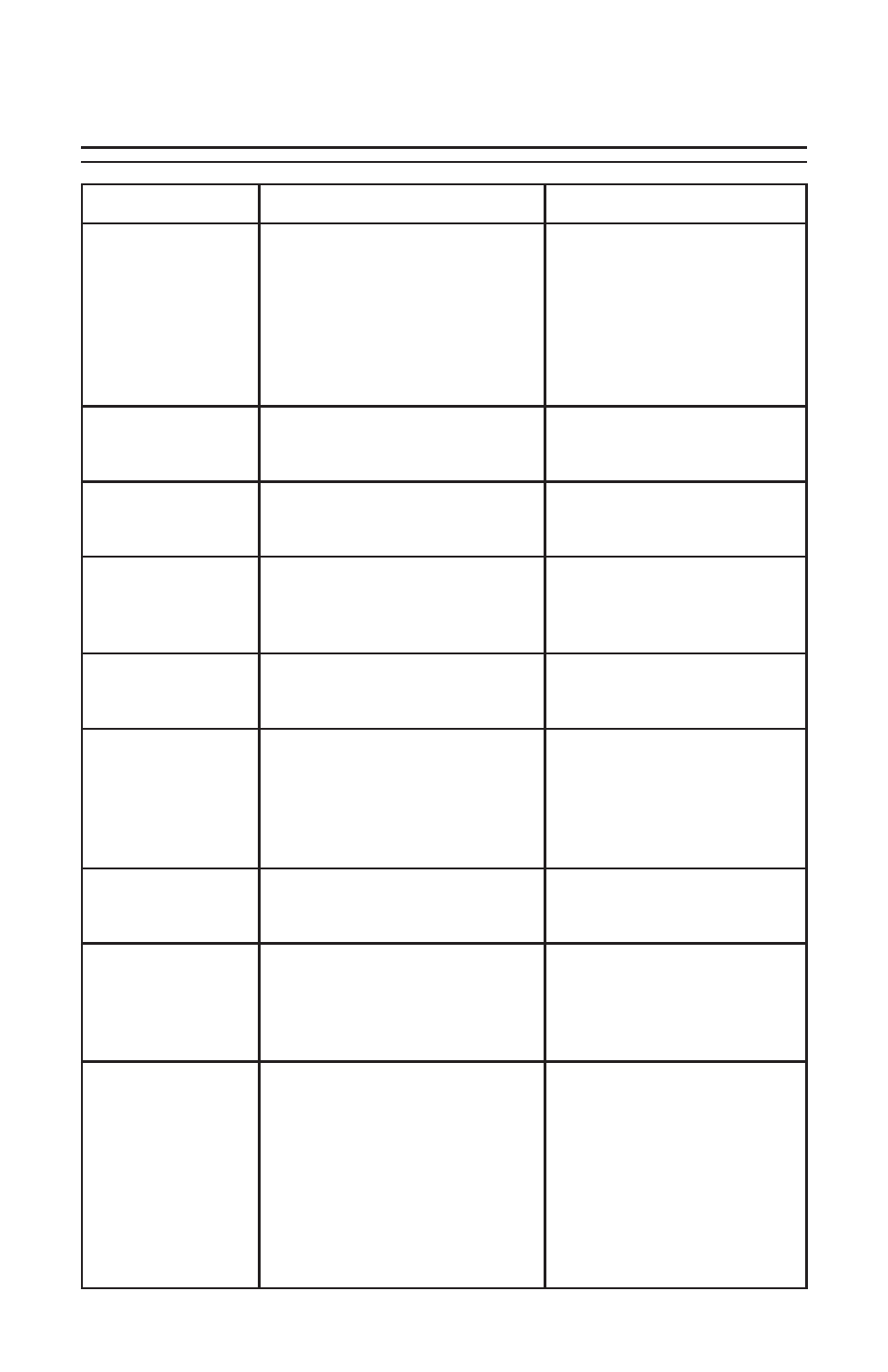

Symptom

Possible Cause

Solution

Excessive over-

spray.

1. Spray pattern adjusted incor-

rectly for your application.

2. Air press too high.

3. Airbrush is too far from sur-

face.

4. Spraying too fast.

1. Adjust the spray regulator.

2. Reduce air pressure.

3. Keep airbrush at recom-

mended distance.

4. Slow down and maintain

consistent, even parallel

stroke.

Spray pattern is

oblong or doesn't

fly straight.

1. Needle has a "hook" at the tip

or has been damaged.

1. Refurbish or replace the

needle.

Spray pattern wider

than normal, even

when adjusted.

1. Nozzle is worn or damaged.

1. Replace spray nozzle.

Material leaks from

jar.

1. Cap not secure.

2. Jar not tight on airbrush body.

3. Leaking from cap vent hole.

1. Tighten.

2. Tighten.

3. Hold airbrush upright; do

not tilt.

Material leaks from

airbrush.

1. Fluid tip loose.

2. Dry or damaged seals.

3. Excessive air pressure.

1. Tighten.

2. Replace seals.

3. Reduce air pressure.

Dry Spray.

1. Inlet air pressure too high.

2. Airbrush too far from surface.

3. Airbrush stroke too fast.

4. Incorrectly thinned paint.

1. Lower inlet air pressure.

2. Keep airbrush at recom-

mended distance.

3. Slow down; use a consis-

tent parallel stroke.

4. Thin paint more.

Paint leaks from

nozzle.

1. Debris will not let the nozzle

seal.

2. O-ring worn.

1. Clean nozzle.

2. Replace O-ring.

Air flow problems.

1. Air hose or connections are

leaking.

2. Valve stem assembly at fault.

1. Replace air hose or re-

establish air hose connec-

tions.

2. Replace the valve stem

assembly

Fluttering, spit-

ting spray, and

general paint flow

problems.

1. Paint or material is thinned

incorrectly.

2. Dried paint or debris on

needle, in nozzle, or on other

internal components.

3. Air flow problem.

1. Thin paint/material to

manufacterer's recommen-

dations; test airbrush by

spraying water.

2. Disassemble and clean air-

brush with special attention

to needle and nozzle.

3. Refer to "Air Flow

Problems" in troubleshoot-

ing.