Installation, Power connections, Engine start control connections – GE ZBTSD User Manual

Page 4: Danger

2

GE Zenith Controls

■

ZBTS / ZBTSD Operation and Maintenance Manual (71R-4000A)

Installation

Table 2

Tightening Torque for Lugs

Socket Size

Across Flats

Torque

Lb. - In.

Lb. - Ft.

45

1/8

4

100

5/32

8

120

3/16

10

150

7/32

12

200

1/4

17

275

5/16

23

375

3/8

31

500

1/2

42

600

9/16

50

Power Connections

GE Zenith transfer switches are supplied with UL listed

solderless screw type terminals as standard for the

Source 1, Source 2 and Load power connections.

Table 1 lists the number and sizes of cable lugs supplied

as standard for each switch amp rating.

Connect the Source 1, Source 2, and Load conductors

to the clearly marked terminals on the transfer switch.

Remove surface oxides from cables by cleaning with a

wire brush. Verify that all connections are correct before

tightening the lugs. All cable lug connections must be

tightened to the proper torque values as shown in

Table 2.

NOTE

:

Do not run cables or wiring behind

front-connected transfer switches.

Table 1

Power Connections: Screw Type Terminals for External Power Connections

Switch Size

(Amps)

40

80

100

150

200, 225, 2500

260, 300, 400

600

800, 1000, 1200

Source 1, Source 2 & Load Terminals

1

#8 AWG to 1/0

Cable Per Pole

Range of Wire Sizes

1

#8 AWG to 1/0

1

#8 AWG to 1/0

1

#8 AWG to 3/0

1

#6 AWG to 250 MCM

1

#4 AWG to 600 MCM

2

#2 AWG to 600 MCM

4

#2 AWG to 600 MCM

Neutral Bar (When Required)

3

#8 AWG to 1/0

No. of Cables

Range of Wire Sizes

3

#8 AWG to 1/0

3

#8 AWG to 1/0

3

#8 AWG to 300 MCM

3

#6 AWG to 300 MCM

3

#4 AWG to 300 MCM

8

#2 AWG to 600 MCM

12

#2 AWG to 600 MCM

1600, 2000

2600, 3000, 4000

Line, Load and Neutral terminals are located in the rear of switch

and arranged for bus bar locations

Engine Start

Control Connections

Engine-start control wires connect to control terminals

beside the Entelli-Switch 250. Engine start terminals are

indicated by a schematic symbol (the symbol indicates

the contact state for a de-energized normal source).

Figure 2 shows the engine-start contacts.

Make all other necessary control connections to the

control panel terminal blocks per the schematics

supplied with the ATS.

NOTE

:

All control wires (18-12 AWG) must be

torqued to 19 in/lbs.

D

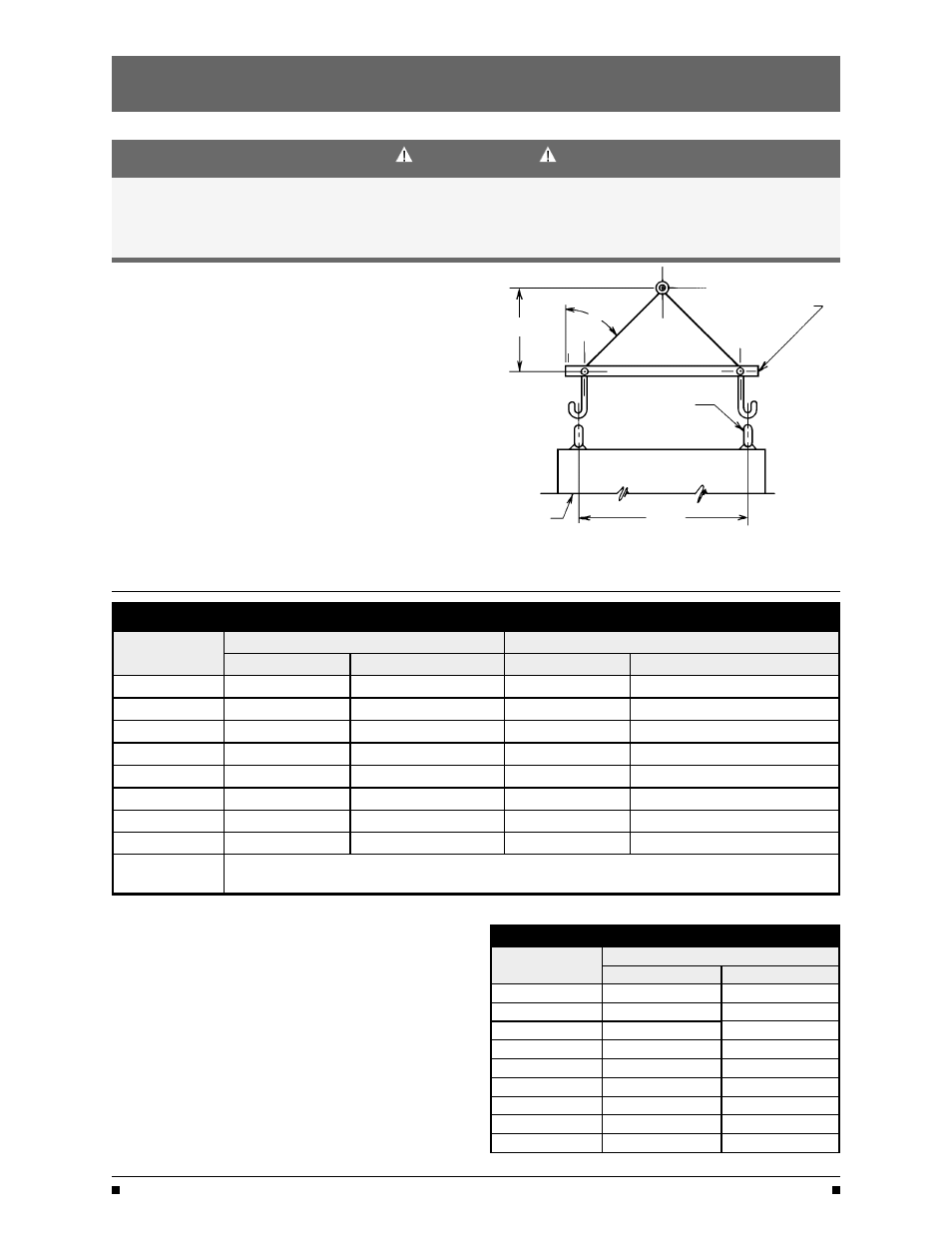

CABINET

LIFTING EYES

SPREADER BAR

H

45°

Figure 1

NOTE

:

When lifting the switch using a spreader bar,

height H must be equal to half of distance D.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.