Faceplate, Centers – Grizzly G9731 User Manual

Page 47

BdYZa<.,(%$<.,(&B[\#H^cXZ.$%%

"(."

Faceplate

GZ[ZgidMounting Chuck or FaceplatedcPage

34

idbdjcii]Z[VXZeaViZidi]Zhe^cYaZ#

I]Z &% [VXZeaViZ ^cXajYZY l^i] i]^h aVi]Z d[[Zgh

V l^YZ gVc\Z d[ jhZh! ^cXajY^c\ bVX]^c^c\ cdc"

XdcXZcig^X ldg`e^ZXZh! higV^\]i ijgc^c\ WZilZZc

XZciZgh!d[["XZciZgijgc^c\!VcYWdg^c\#

I]Z iddah cZZYZY [dg bdjci^c\ V ldg`e^ZXZ l^aa

kVgnYZeZcY^c\dci]ZineZd[hZijendj]VkZ#

Failure to properly secure a workpiece to the

faceplate could cause the workpiece to be

thrown from the lathe with deadly force at

the operator or bystanders. Use a minimum

of THREE independent clamping devices to

hold the workpiece, clamp counter-weights

to the faceplate to balance it, and always use

a low spindle speed.

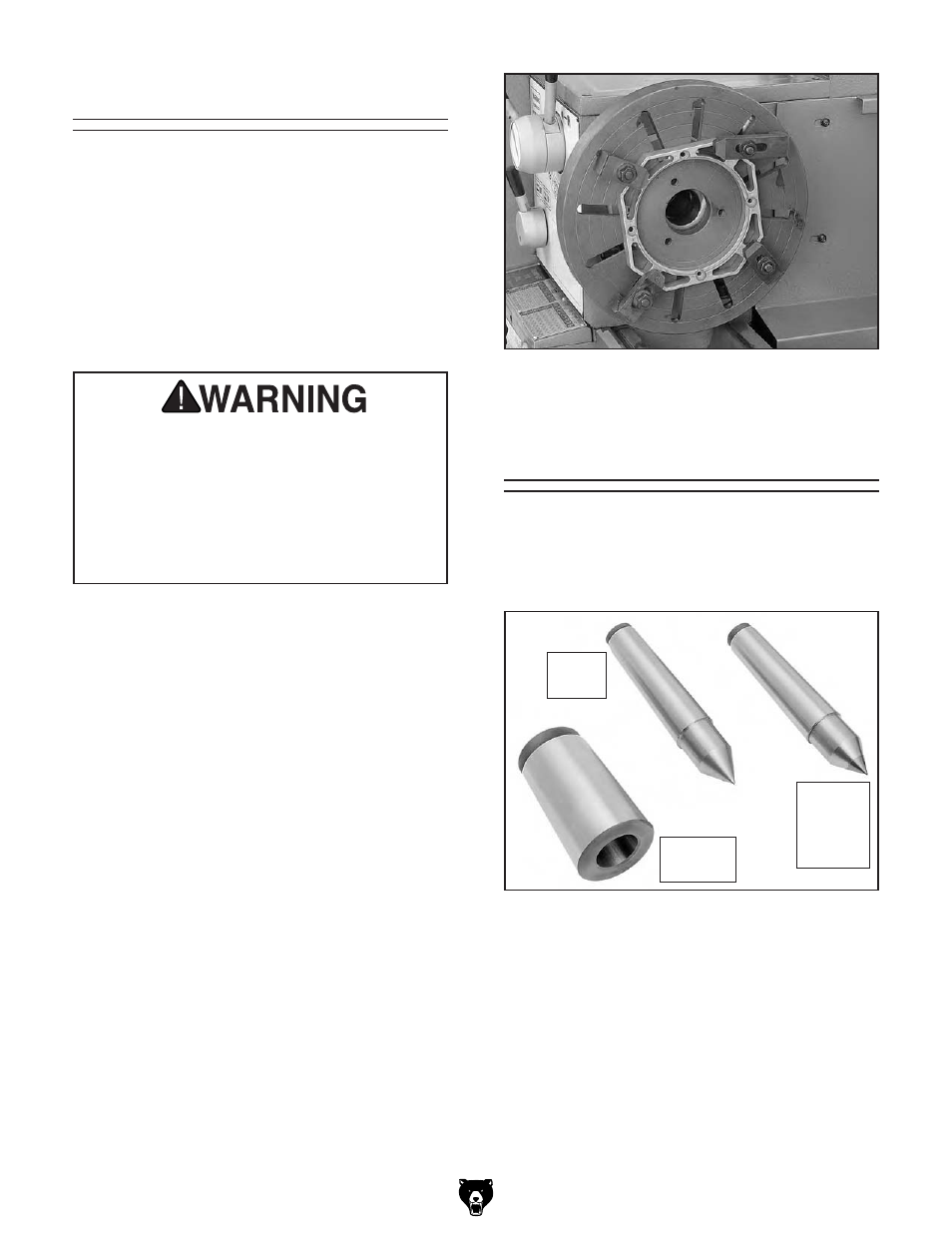

Figure 48.

XaVbeZYidV[VXZeaViZ# To mount a non-concentric workpiece to the 1. 9>H8DCC:8IA6I=:;GDBEDL:G 2. EgdiZXii]ZWZYlVnl^i]Ve^ZXZd[eanlddY# 3. L^i]i]Z]Zaed[Vcdi]ZgeZghdcdgVldg`e^ZXZ hjeedgi^c\ YZk^XZ! edh^i^dc i]Z ldg`e^ZXZ 7Z hjgZ id iV`Z ^cid VXXdjci i]Z gdiVi^dcVa Centers Figure 49 h]dlhi]ZBI(YZVYXZciZgh^cXajYZY l^i] i]Z aVi]Z# >c VYY^i^dc! Vc BI)#*¶BI( Figure 49. IVeZgZYhe^cYaZhaZZkZVcYYZVY XZciZgh# IVeZgZY HaZZkZ 9ZVY 8ZciZg 8VgW^YZ" I^eeZY 9ZVY 8ZciZg

faceplate:

dcidi]Z[VXZeaViZVcY[^gbanXaVbe^i^ceaVXZ

l^i]Vb^c^bjbd[i]gZZ^cYZeZcYZciXaVbe"

^c\YZk^XZhhZZFigure 48[dgVcZmVbeaZ#

VcYXjii^c\[dgXZhi]Vil^aaWZVeea^ZYidi]Z

ldg`e^ZXZl]ZcXaVbe^c\^iidi]Z[VXZeaViZ#

>[cZXZhhVgn!jhZXdjciZg"lZ^\]ihidWVaVcXZ

i]ZVhhZbWan#

iVeZgZY he^cYaZ haZZkZ ^h ^cXajYZY [dg bdjci^c\

i]ZXZciZgh^ci]Zhe^cYaZ#