System grounding – Grizzly G5954 User Manual

Page 22

-20-

G5954 5HP Dust Collector

—If the CFM for your static pressure loss is

above the requirement of the woodworking

machine, then the line will most likely be

successful.

—If the CFM for your static pressure loss is

below the requirement of the machine, then

that line will not effectively collect dust. You

must modify some of the factors in that line

to reduce the static pressure loss. Some of

the ways to do this include installing larger

duct, reducing amount of flexible duct

used, increasing machine dust port size,

moving machine closer to dust collector

to eliminate duct length, and reducing 90˚

elbows or replacing them with 45˚ elbows.

Since plastic hose is abundant, relatively inexpen-

sive, easily assembled and air tight, it is a very

popular ducting material. We recommend using

flexible hose (flex-hose) to connect the wood-

working machine to the dust collector. However,

plastic flex-hose and plastic duct can create a

static electrical build up, which will build until it

discharges to a ground. If a grounding medium

is not available to prevent static electrical build

up, the electrical charge will arc to the nearest

grounded source. This electrical discharge may

cause an explosion and fire inside the system.

To protect against static electrical build up inside

a non-conducting duct, a bare copper wire should

be placed inside the duct along its length and

grounded to the dust collector. You must also

confirm that the dust collector is continuously

grounded through the electrical circuit.

If you connect the dust collector to more than one

machine by way of a non-conducting branching

duct system and blast gates, the system must

still be grounded via copper wiring as above, with

the wire attached to each grounded machine and

dust collector.

System Grounding

Be sure that you extend the bare copper wire

down all branches of the system. Do not forget

to connect the wires to each other with wire nuts

when two branches meet at a “Y” or “T” connec-

tion. If using plastic blast gates to direct air flow,

the grounding wire must be jumped (

Figure 25)

around the blast gate without interruption to the

grounding system.

Figure 25. Ground jumper wire when using

plastic blast gates and metal duct.

Plastic

Blast

Gate

Metal Duct

Copper

Ground

Wire

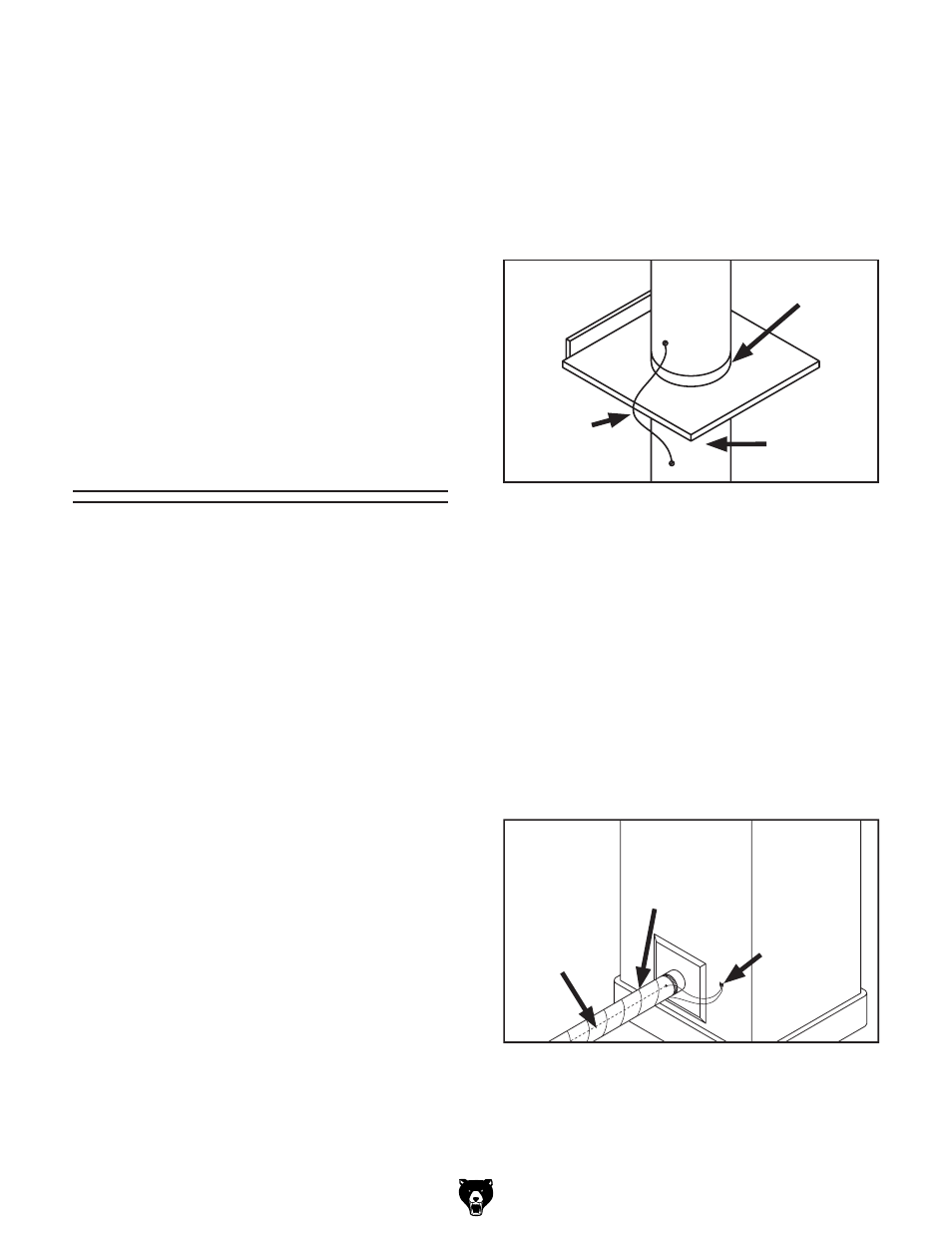

Figure 26. Flex-hose grounded to machine.

Ground

Screw

Flex-Hose

Internal

Ground

Wire

External

Ground

Wire

We also recommend wrapping the outside of all

plastic ducts with bare copper wire to ground the

outside of the system against static electrical

build up. Wire connections at Y’s and T’s should

be made with wire nuts.

Attach the bare ground wire to each stationary

woodworking machine and attach to the dust

collector frame with a ground screw as shown in

Figure 26. Ensure that each machine is continu-

ously grounded to the grounding terminal in your

electric service panel.