Fvr-c9s-7ux – GE FVR-C9S-7UX User Manual

Page 38

38

FVR-C9S-7UX

6) It is important that all lead length are kept

as short as possible and that incoming

mains and outgoing motor cables are kept

well separated.

7) Segregate power cables from control

wiring as possible as you can, and avoid

parallel cable runs to minimize “noise cou-

pling”. Wherever runs of power and control

cable must cross, try to achieve this at right

angles.

8) FVR drives should be installed, and are

designed to operate, within an electrically

shielded metal enclosure.

The RFI filters range are designed especially

for the FVR drive and help to ensure EMC

compliance of machinery an installations

using the drives. The drives may be mounted

on top of the filter using the integral fixing

positions, the intention being that valuable

space inside wiring cabinets may be saved.

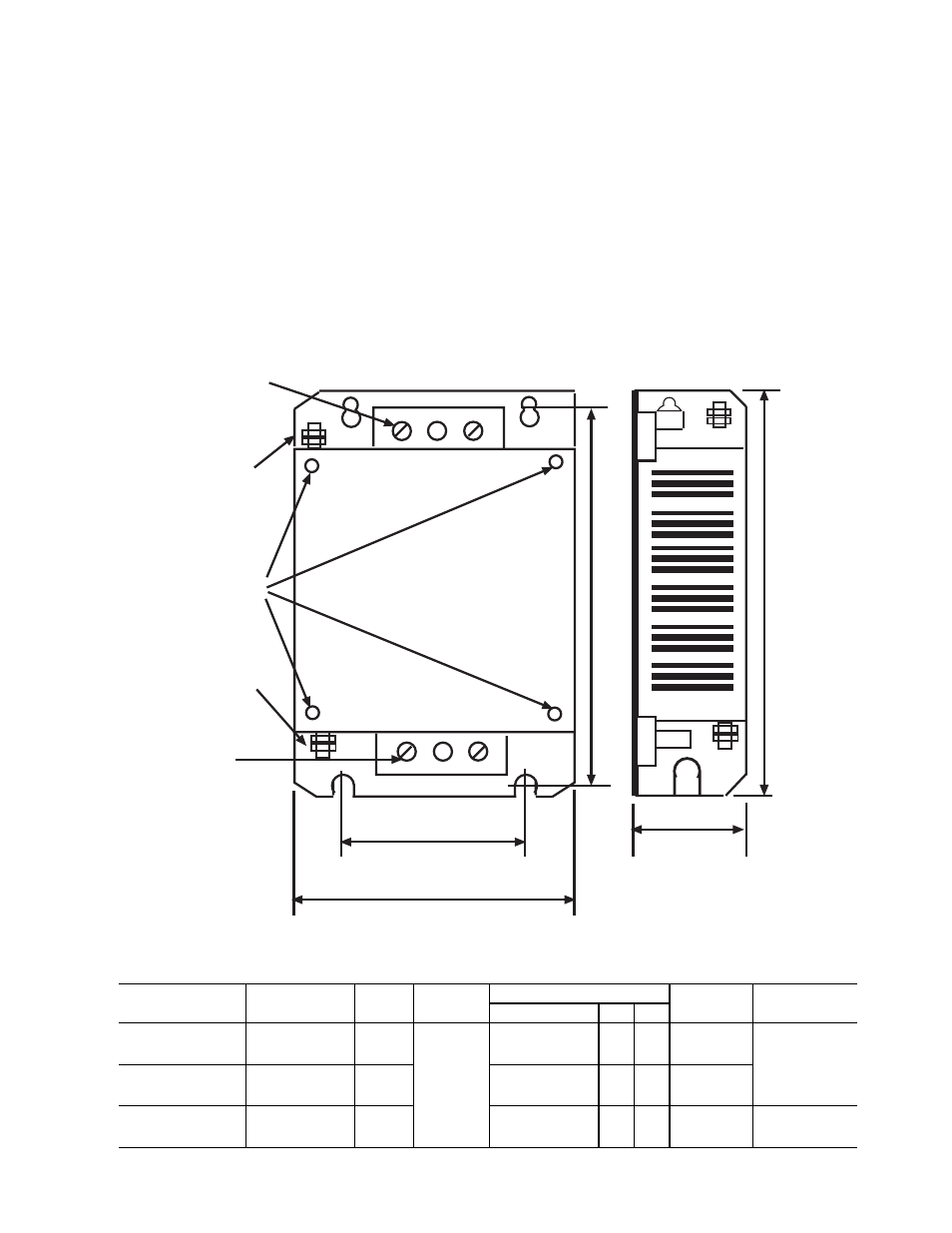

(Refer to Fig. 1 and Table 1)

Filter

Applied

Rated

Max Rated

Dimensions inches

Drive

Sub

Part No.

Drive

Current

Voltage

L x W x H

X

Y

Fixings

Filters

EFL-0.2C9-7

FVRF12C9S-7UX

3A

6.69 x 3.35 x 1.38 1.97

6.1

M4 0.16

Ferrite

FVRF25C9S-7UX

x0.63 (2pcs.)

OC1x (1 pcs.)

EFL-0.75C9-7

FVRF50C9S-7UX

10A

1-Phase

6.69 x 3.35 x 1.38 1.97 6.10

M4 0.16

FVR001C9S-7UX

240 VAC

x0.63 (2 pcs.)

EFL-2.2C9-7

FVR002C9S-7UX

16A

7.09 x 4.53 x 1.38 3.50 6.50

M4 0.16

Ferrite

x0.63 (4 pcs.)

OC2x (1 pcs.)

7-'006

Mains input

terminals

Earth Stud

Drive fixing

positions

Earth Stud

Load terminals

to drive

input

Y

X

W

L

N

LINE

LOAD

L’

N’

L

H

Fig. 1 RFI Filters

Table 1 RFI Filter Dimensions Conforms to EN55011 Class B