Troubleshooting continued – Global Machinery Company 50L User Manual

Page 13

13

Troubleshooting continued

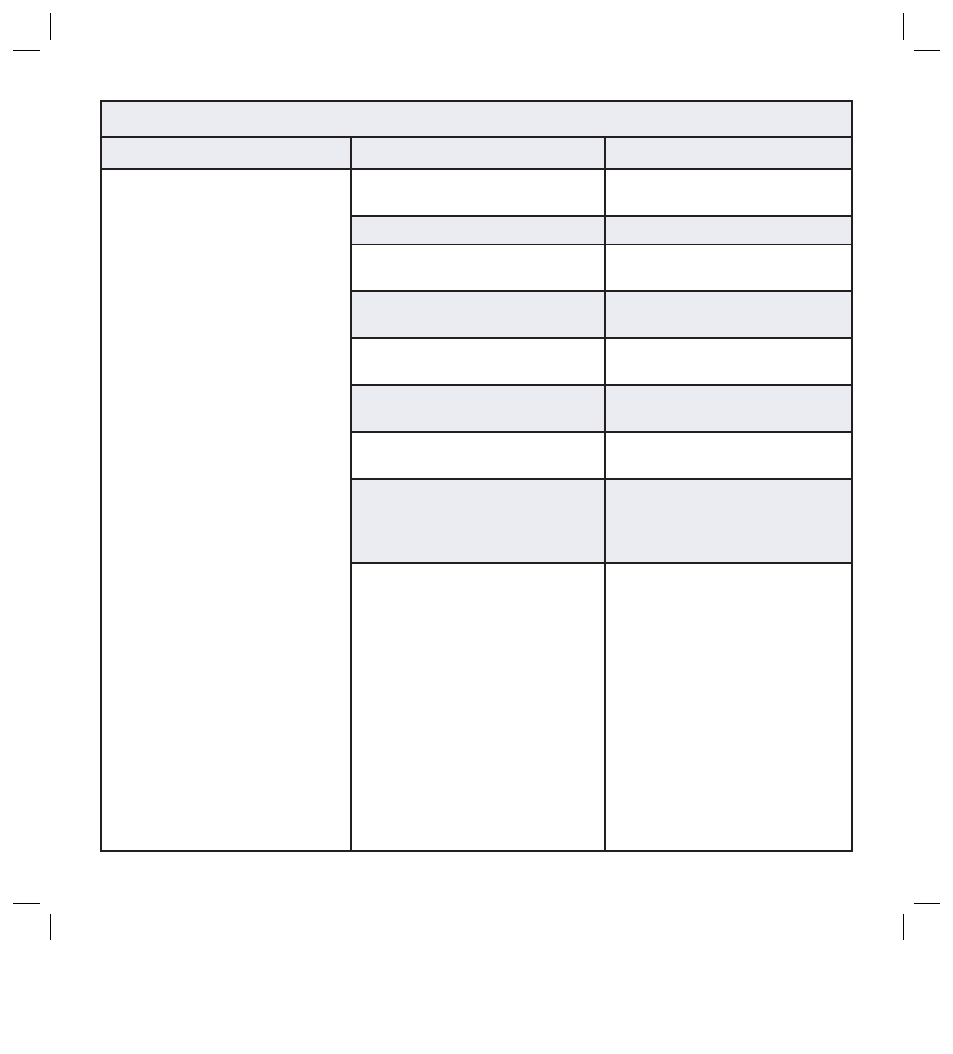

Problem

Possible Cause

Suggested Remedy

Insufficient pressure or decreased

outlet capacity

Motor running too slow

Use authorised service centre to check

and repair if necessary

Dirty air filter cartridge

Clean or replace the filter cartridge

Leaking safety valve

Use authorised service centre to repair

or replace the switch

Leaking pipe

Use authorised service centre to check

and repair if necessary

Damaged gasket

Use authorised service centre to check

and repair if necessary

Damaged or carbon coated valve seat

Use authorised service centre to check

and repair if necessary

Damaged piston ring or cylinder

Use authorised service centre to check

and repair if necessary

Open drain cock

Check the drain cock, make sure it is

closed. If not immediately switch off the

unit as per the shut down instructions

and close the drain cock.

Air fittings leaking

Check all air fittings. Make sure that

they are tight and not leaking at the

joins. If a quick release fitting is leaking,

disconnect it and reconnect it. If it

continues to leak replace the defective

fitting(s). If a male or female fitting is

leaking around the thread tighten using

a spanner. If the fitting is already tight

and can’t be tightened, unscrew the

connection and remove the Teflon tape.

Examine the condition of the fitting(s).

If the a fitting(s) is damaged replace

and reassemble using Teflon tape on

threaded fittings. If the fittings are OK

reapply Teflon tape and reassemble.