Test run – Grizzly T10010 User Manual

Page 11

Model T10010 Wet Grinder

-11

-

Test Run

Once your Model T10010 is positioned,

test run the machine to make sure it runs

properly.

If, during the test run, you cannot easily

locate the source of an unusual noise or

vibration, stop using the machine immedi-

ately, then review the Troubleshooting on

Page 20

.

If you still cannot remedy a problem, con-

tact our Tech Support at (570) 546-9663 for

assistance.

To test run the machine:

1.

Make sure you have read the safety

instructions at the beginning of the

manual and that the grinder is setup

properly.

2.

Make sure all tools and objects used

during set up are cleared away from

the grinder.

3.

Make sure the switch is in the OFF

position.

4.

Connect the grinder to the power

source.

5.

Flip the switch to the right to turn the

grinder ON. Make sure that your hand

stays poised over the switch in case

you need to quickly turn the machine

OFF

.

6.

Listen to and watch for abnormal nois-

es or actions. Under normal conditions,

the grinder will make a humming noise,

with only minor vibration.

— Strange or unusual noises should

be investigated and corrected

before operating the machine fur-

ther. Always disconnect the machine

from power before investigating or

correcting potential problems.

7.

Turn the grinder OFF.

8.

Remove the switch disabling key and

attempt to turn the machine ON.

— If the grinder does not start, the

switch disabling feature is working.

— If the grinder starts, stop it. The

switch disabling feature is not work-

ing. This safety feature must work

properly before proceeding. Call

Tech Support for help.

4.

An undamaged wheel will emit a clear

metallic ring or “ping” sound in each

of these spots. A damaged wheel will

respond with a dull thud that has no

clear tone.

5.

If you determine from the ring test that

the wheel is damaged, DO NOT use it!

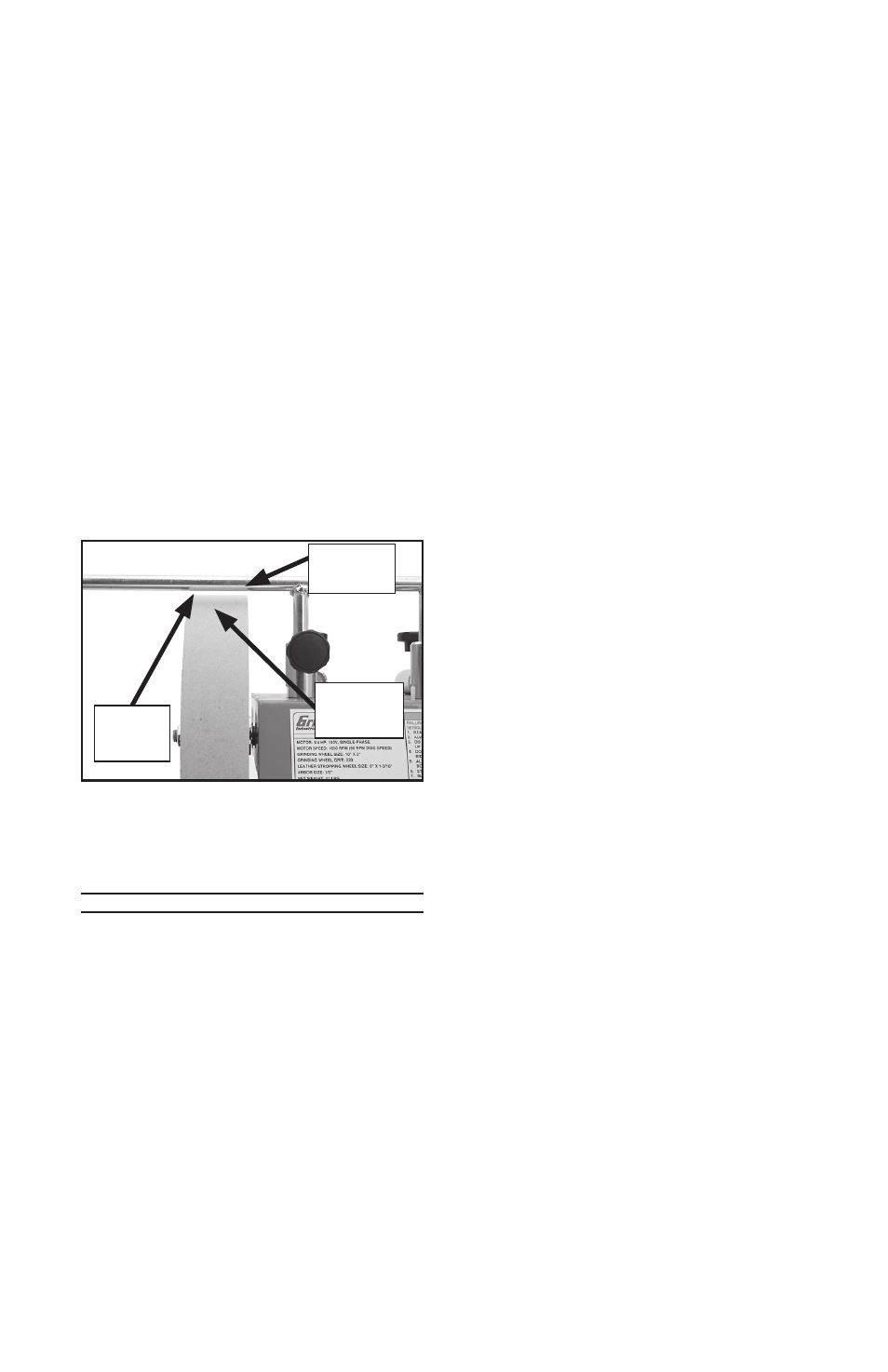

Finally, check that the grinding surface

is square.

Lower the universal support to

1

⁄

16

"-

1

⁄

8

" above the grinding wheel. Using

the universal support as a visual guide,

check that the entire surface of the grind-

ing wheel is consistent and parallel to the

universal support, as shown in Figure

5

. (If this is not the case, see Wheel

Dressing

on Page 16.)

Figure 5.

Parallel check.

Universal

Support

Grinding

Surface

Check

Parallel