Global Machinery Company SPJ2HM User Manual

Page 10

10

Position 1. LOW – Minimal pendulum action for cutting

most metal.

Position 2. MEDIUM – Medium pendulum action for

cutting plastics, and hardwoods.

Position 3. FAST – Maximum pendulum action for the

highest orbital action and faster cutting in plywood and

soft woods.

Scrolling control

Note.

The scrolling feature allows the blade to be rotated

360° for maximum blade control when cutting curves and

intricate work.

Ensure you use a blade

specifically intended for curve

cutting (eg. scroll cutting blade).

Do not place excess force when

turning the blade as it may break.

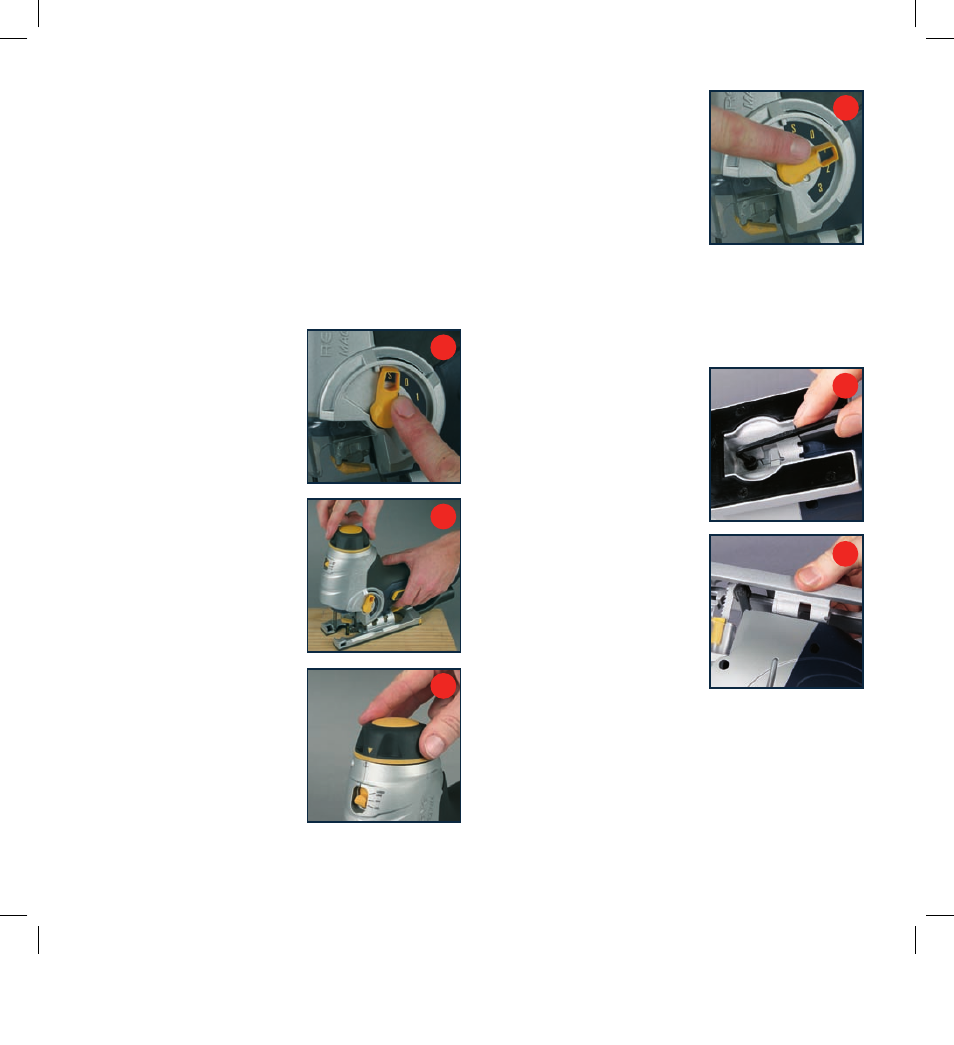

Set the pendulum lever (5) to

Position “S” (fig M).

Note.

The scrolling feature

will not operate if the lever is

positioned at 0,1,2 or 3.

During operation place one hand

firmly on the hand grip, place

your other hand on the scrolling

control knob (4) and rotate it

- using it to guide the blade along

your cutting line (fig N).

To disengage the scroll function,

to enable standard or pendulum

action cutting, rotate the scrolling

control knob (4) back to the

forward position (with the arrows

on the scrolling control and

jigsaw housing aligned) (fig O).

The pendulum lever (5) can

now be moved to the required

position for straight, standard or

pendulum cutting (fig P).

Angle adjustment

Note.

The jigsaw shoe can

be angled to enable bevel or

chamfer cuts. There are preset

bevel settings at 0° and 45° for

quick adjustment.

Always ensure the tool is switched off and the plug

is removed before carrying out any adjustments or

maintenance procedures.

With the jigsaw upside down

on a solid surface loosen the

hex screw located on the

underside of the tool using hex

key (26) (fig Q).

Move the shoe plate slightly

back. It can now be tilted to

the required angle (between

0° and 45°) as indicated on

angle scale (16) (fig R).

With the shoe plate inclined at

45° left or right, or at 0°, the

plate can be locked at one of

these angles by sliding the

shoe plate forwards so that the

indentation in the bridge of the

sole plate fits over the bevel

locating pin (19).

To secure the sole plate at a particular angle, retighten the

hex screw.

M

N

O

P

Q

R