Disc sanding sharpening, Contour sanding, Notice – Grizzly G3105 User Manual

Page 16

-14-

G3105 Combination Sander

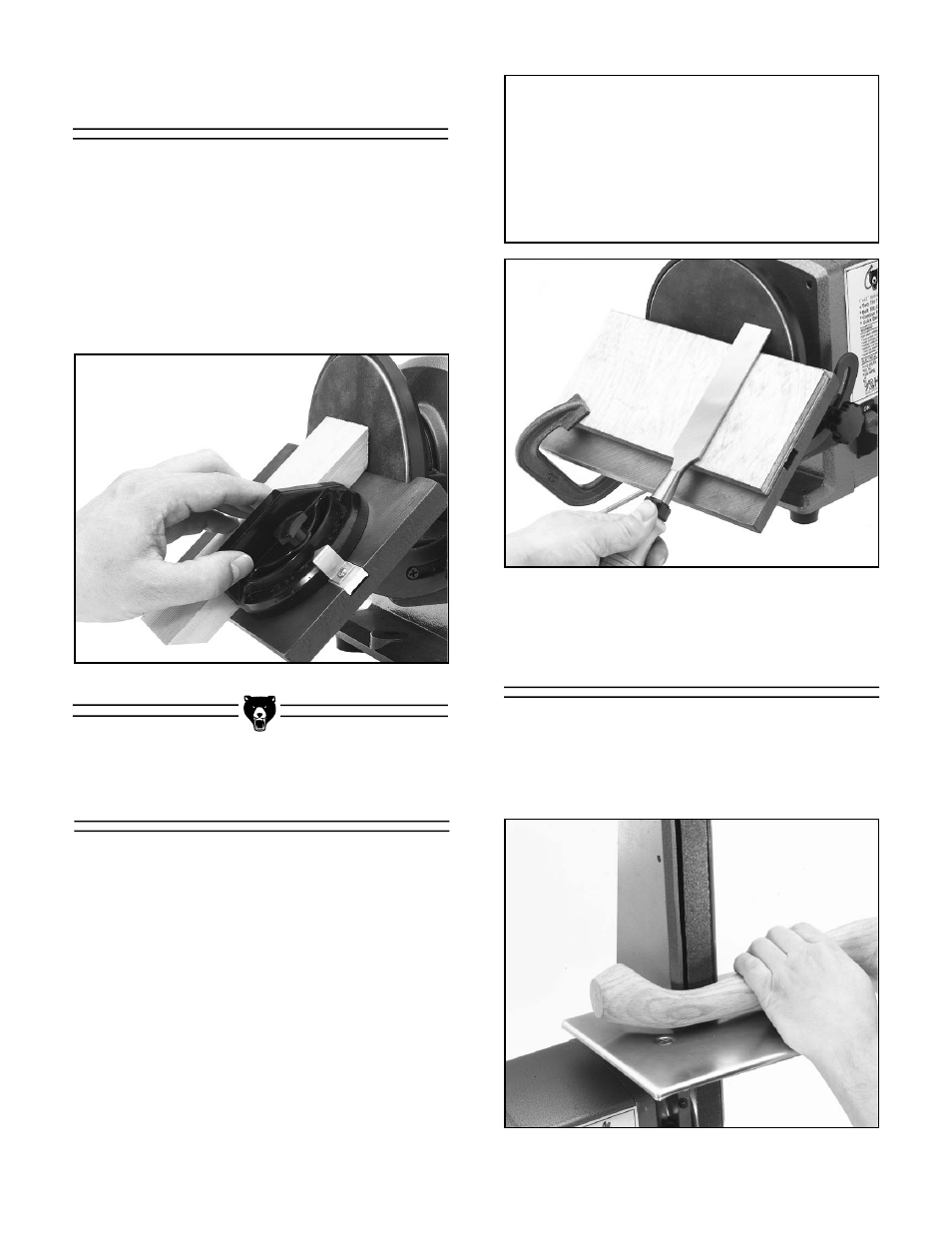

Disc sanding is well suited for finishing small flat

surfaces and curved edges. The down (right)

side of the disc is the working area. The disc

moves fastest and removes the most material at

the outer edge. A miter gauge that fits in the slot

in the table is provided. Use it to secure the work-

piece and to hold the proper angle when disc

sanding. See

Figure 10

.

Tilt table to the desired sharpening angle and

tighten the locking knobs. Using C-Clamps,

attach a suitable wood scrap to the table. This

wood table should allow the flat shank of the chis-

el or knife to sit flat so the proper angle against

the disc can be achieved. See

Figure 11.

This

acts as an auxiliary table to support the work-

piece. This table should be

1

⁄

16

" away from the

belt. It may be necessary to cut a notch in your

auxiliary table to achieve this clearance.

Disc Sanding

Sharpening

Figure 10.

Disc sanding.

Contour Sanding

Remove the platen to allow the 1" sanding belt to

follow the shape of your workpiece. Slowly feed

the workpiece into the belt. Do not apply too

much pressure while sanding.

Figure 11.

Auxiliary table for sharpening.

Figure 12.

Contour sanding.

NOTICE

When grinding or polishing metal, the use

of a metal abrasive is recommended. The

use of a grease stick may also be neces-

sary when grinding soft metals such as alu-

minum or brass.