Adjusting the belt – Grizzly G8030 User Manual

Page 18

-16-

G8030 3 H.P. Overarm Router

3.

Tighten the motor mount plate bolts.

4.

Check tension. If it is not correct, repeat

Steps

1 to 4.

Adjusting the Belt

SECTION 5: ADJUSTMENTS

A slipping belt wastes power, causes control

problems and wears the belt out prematurely. You

should be able to deflect the belt

1

⁄

2

" to

3

⁄

4

" with

moderate finger pressure. The belt will slip if too

loose and squeal or cause vibration if too tight.

If the belt is too loose, or too tight:

1.

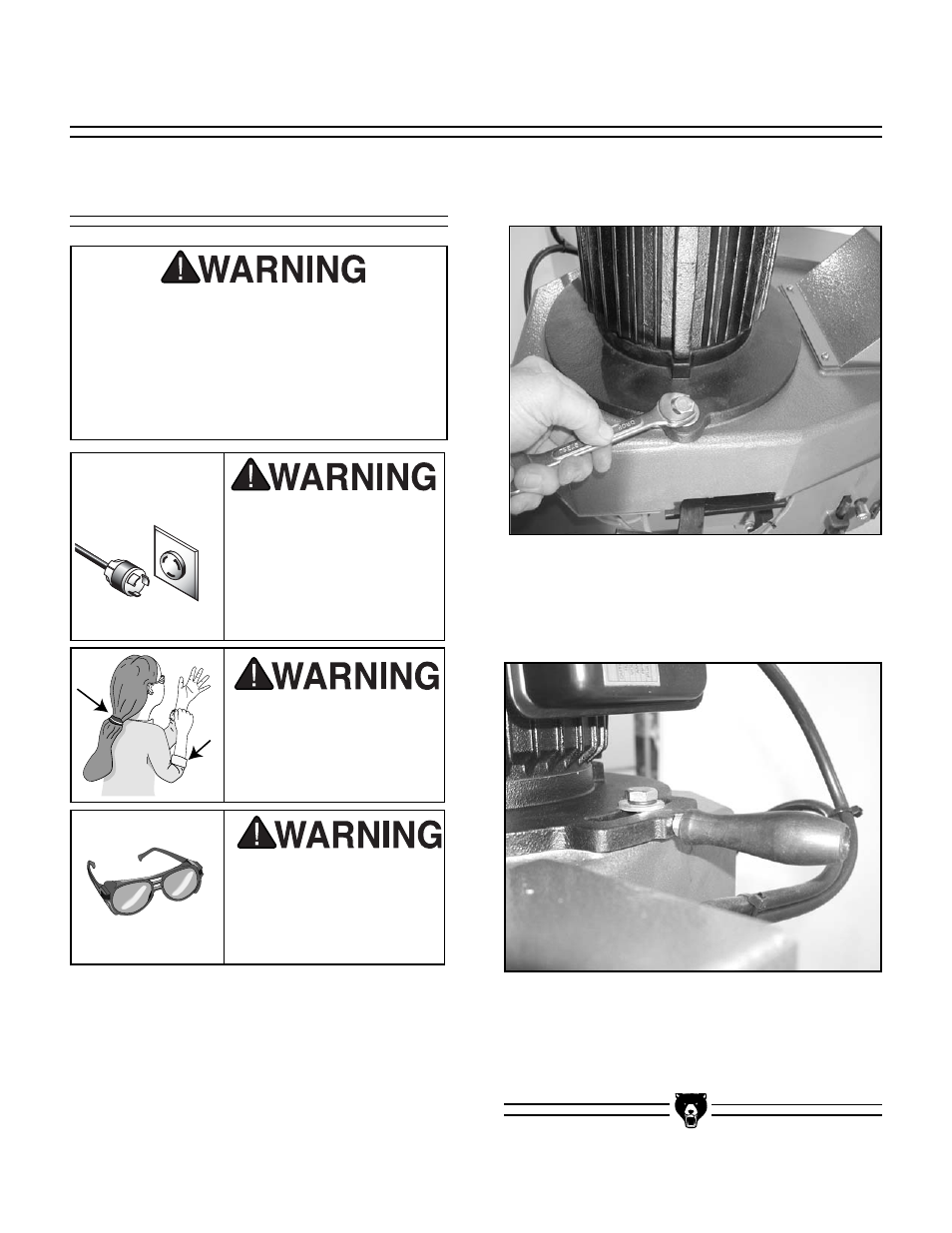

Loosen the bolts around the motor base as

shown in

Figure 13.

Figure 13

. Loosening motor mount bolts.

2.

Locate the handle on the motor base, and use

it to pull the belt tight. A backwards pull tight-

ens the belt as shown in

Figure 14.

Figure 14

. Belt adjustment handle.

All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are

formed. This is removed at the factory.

Sometimes, though, a bit of flashing might

escape inspection. Please examine the

edges of all die-cut metal parts before han-

dling them. Serious injury may occur.

Disconnect power to the

machine when perform-

ing any maintenance,

assembly or adjust-

ments. Failure to do this

may result in serious

personal injury.

!

Keep loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Wear safety glasses dur-

ing the entire adjustment

process. Failure to com-

ply may result in serious

personal injury.