Feed rate – Grizzly G0592 User Manual

Page 26

-24-

G0592 Metal Cutting Bandsaw

The table shown in

Figure 22 is a sampling of

speed rates for various materials. Use these as a

guideline.

The speed at which the saw blade will cut through

a workpiece is controlled by blade type, feed rate,

and feed pressure. The feed rate is controlled by

two knobs on the control panel.

Note: If a lubricant is used on the cut, the feed

rate can be increased by approximately 15%.

To set the feed rate:

1. Raise the bow to the highest position.

2. Set the Feed Rate Dial to the desired feed

rate. Range is from 1 being slowest, to 9

being fastest.

3. Turning the Feed Control Knob to the left to

lower the bow at the feed rate you have set.

Turning the knob to the right locks the bow in

position.

• If you get a tightly curled, warm shavings,

brown to black in color, you are using too

much downward pressure.

• Blue looking chips are from extreme heat

with a high band saw speed.

• Thin powder-like chips are from insuffi-

cient feed pressure. This will dull your blade

rapidly.

• The best cut and feed rate will give you

evenly shaped spiraled curls with very little

color change, if any at all.

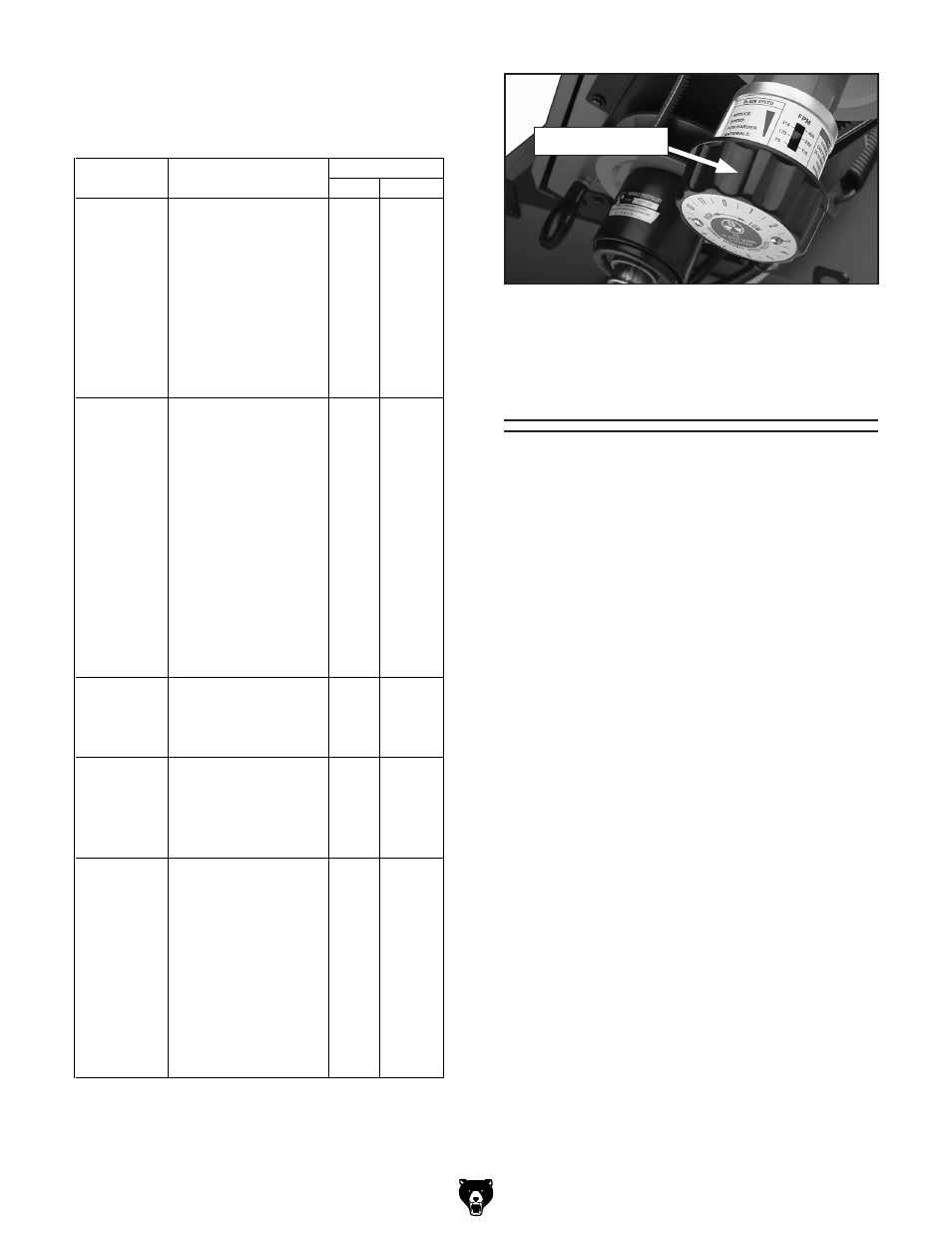

Feed Rate

Figure 23. Feed rate dial (shown with guard

removed).

Feed Rate Dial

Material

Alloy ASTM Number

Ft/Min Mtrs/Min

Copper

173,932

314

96

Alloys

330,365

284

87

623,624

264

81

230,260,272

244

74

280,264,632,655

244

74

101,102,110,122,172

234

71

1751,182,220,510

234

71

625, 706, 715, 934

234

71

630

229

70

811

214

65

Carbon

1117

339

103

Steels

1137

289

88

1141,1144

279

85

1141 High Stress

279

85

1030

329

100

1008,1015,1020,1025

319

97

1035

309

94

1018,1021,1022

299

91

1026,1513

299

91

A36 (SHAPES),1040

269

82

1042,1541

249

76

1044,1045

219

67

1060

199

61

1095

184

56

Nickle

8615, 8620, 8622

239

73

Chrome

4340, E4340, 8630

219

67

Molybdenum 8640

199

61

Alloys

E9310

174

53

Tool Steels

A-6

199

61

A-2

179

55

A-10

159

49

D-2

90

27

H-11,H-12,H-13

189

58

Stainless

420

189

58

Steels

430

149

46

410,502

140

43

414

115

35

431

95

29

440C

80

24

304, 324

120

36

304L

115

35

347

110

33

316, 316L

100

30

416

189

58

Blade Speed

Figure 22. Material speed table.