GE VERTICAL DRILLING MOTOR GE752 User Manual

Page 78

GEK–91584D, Vertical Drilling Motor, Type GE752

78

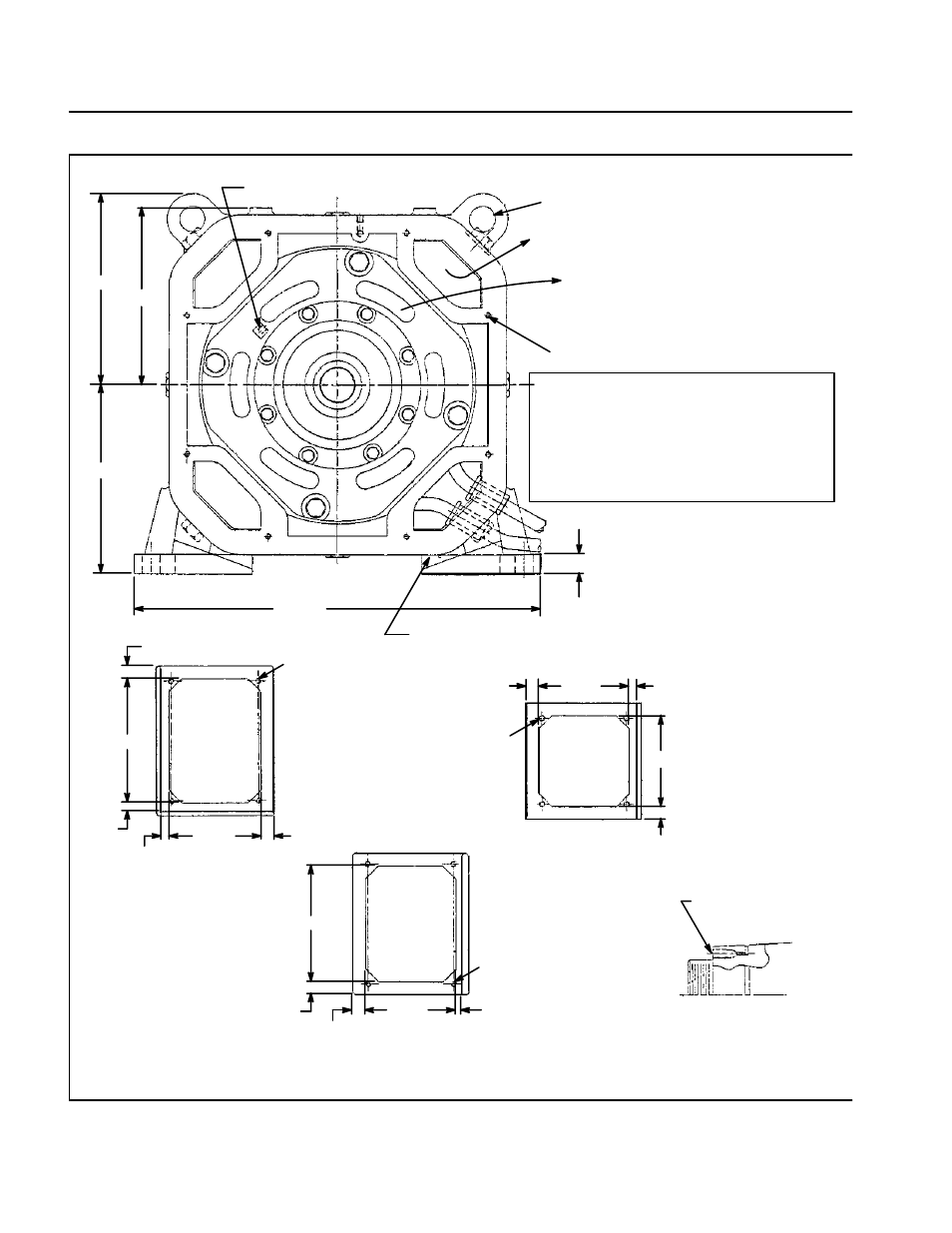

FIG. 49. OUTLINE, US1, AUT (41E903745, CHG. A). E–37954B

+

– .25

16.82

15.53

16.656

.000

.010

36.000

.000

.010

.50–13 TAP 1.00 DEEP

(8HOLES)

.25 NPT FOR

REGREASING

2.25 DIA. (3 HOLES)

FOR LIFTING

AIR OUT

(4 CORNERS)

AIR OUT

+

–

+

–

1.72

THIS AREA OF FOOT FLUSH

WITH FRAME FACE.

BOTH SIDES

FI

F2

.375–24 THREAD

VIEW SHOWING HYDRAULIC

PUMP OFF FOR HUB

BOTH ENDS

1.12

8.00

.50

FLAT

10.25

1.12

VIEW AT ”C”

SHOWING FLANGE

WITH COVER

REMOVED

1.12

11.00

.75

FLAT

8.00

1.12

.75

FLAT

VIEW AT ”A”

SHOWING FLANGE

WITH COVER

REMOVED

VIEW AT ”B”

SHOWING FLANGE

WITH COVER

REMOVED

.50–13 TAP THRU

(4 HOLES)

1.12

8.00

.75

FLAT

1.12

8.00

.50–13 TAP THRU

(4 HOLES)

.50–13 TAP THRU

(4 HOLES)

IMPORTANT:

THE ELECTRICAL EQUIPMENT SHOULD

BE LOCATED IN A SPACE WHICH–

(1) PROVIDES SUFFICIENT ACCESSIBILITY

FOR BRUSH INSPECTION.

(2) ALLOWS REMOVAL OF ALL THE

BRUSHES AND PIGTAIL FASTENERS.

(3) ALLOWS MAINTENANCE PERSONNEL

TO COMPLY TO THE GE MAINTENANCE

INSTRUCTION SPECIAL REQUIREMENTS

APPROX. WEIGHT:

GE–752–AUT = 7035 LBS.

AIR FLOW REQUIREMENTS:

2300 CFM OF STANDARD AIR

MINIMUM, 900 HP.

2800 CFM OF STANDARD AIR

MINIMUM, 1000 HP.

GE752AUT AND US1 SHOWN IN

MAIN VIEWS.