Armature creepage band replacement, Rewinding armature, Riser width – GE VERTICAL DRILLING MOTOR GE752 User Manual

Page 37: Diameter

Vertical Drilling Motor, Type GE752, GEK–91584D

37

ARMATURE

Creepage Band Replacement

Because of its superior adhesion qualities, the Teflon

creepage band on the outer end of the commutator

should be applied using the “hot bond” process. A copy

of this process is included in each Teflon Band Kit, Part

No. 76518, which can be ordered from the following ad-

dress:

General Electric Company

Insulating Materials Product Section

One Campbell Road

Schenectady, NY 12345

Attn: Customer Service

NOTE: The Teflon band is not included in the

kit, but can be ordered through normal Renewal

Parts channels.

Inspect the Band

1.

There should be no gaps at the joint or between

the edge of the Teflon band and the copper bars.

2.

The band surface must be smooth, free of var-

nish and bonded to the underlay material. There

must not be any bubbles under the Teflon or

buckling of the band.

3.

The surface must be free of damage including

scratches and cuts.

Rewinding Armature

The armature must be rewound if any coils are

shorted or grounded.

Riser Width

During the rewinding procedure, the TIG welds on

the commutator risers are machined to break the arma-

ture coil connections. Machining reduces the width of

the risers 1/32 to 1/16 in. each time, which in turn de-

creases the current–carrying capacity of the risers.

If the calculated width of the risers (after machining)

will be less than the Minimum Permissible Riser Width

listed in the DATA section, a new commutator must be

installed before new armature coils are assembled.

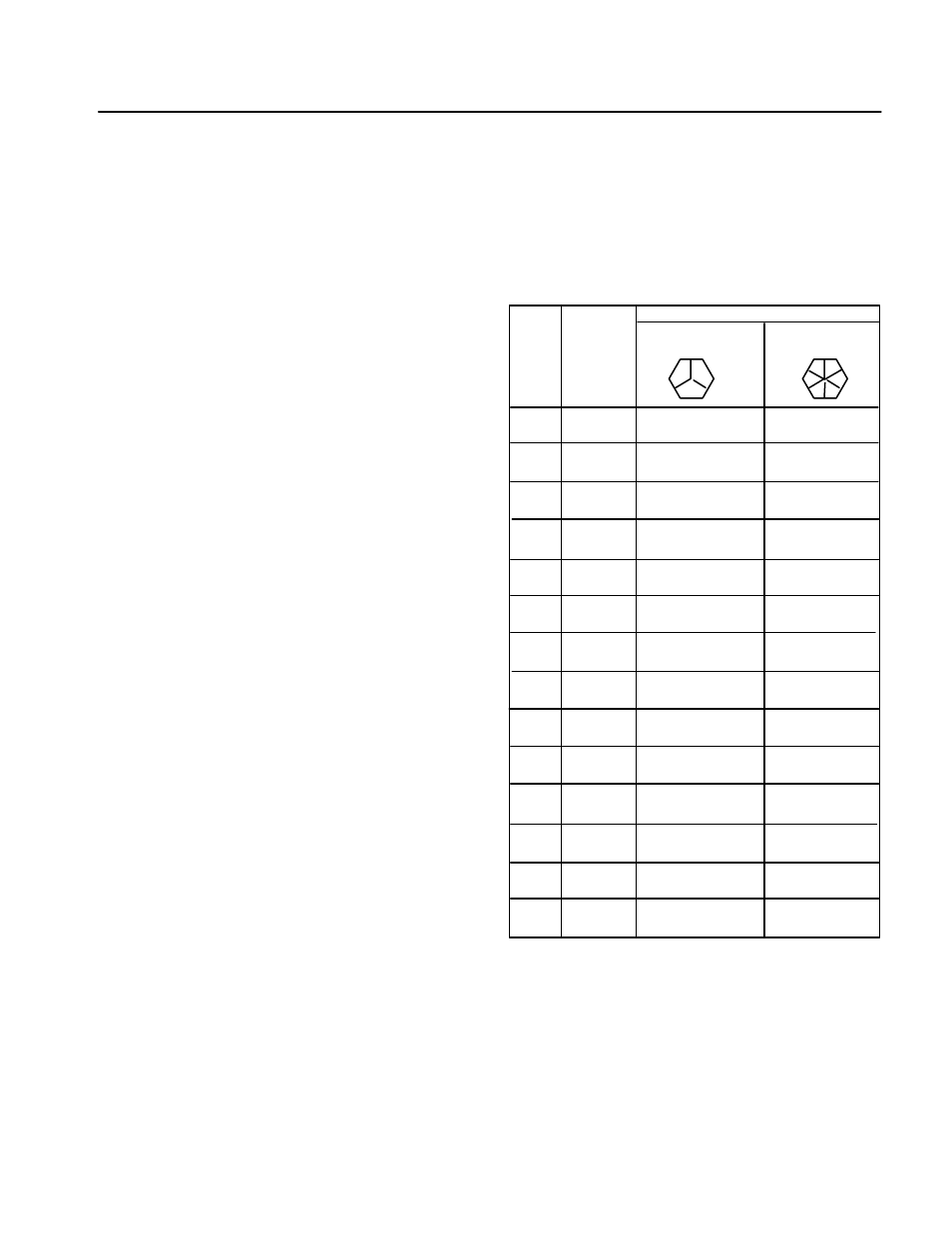

TABLE 3

STANDARD BOLT TORQUE VALUES

USE THE TORQUE VALUES IN THIS TABLE AS A GUIDE TO IN-

SURE SATISFACTORY TIGHTENING OF BOLTS AND NUTS

WHERE A SPECIFIC VALUE IS NOT GIVEN IN THE INSTRUC-

TIONS.

*INCLUDES SOCKET HEAD SCREWS.

1/4

20

5–8

10–12

28

5–8

10–12

5/16

18

12–15

18–21

24

12–15

20–23

3/8

16

20–25

30–36

24

25–28

34–40

7/16

14

35–40

50–56

20

40–45

60–65

1/2

13

55–60

80–90

20

60–70

95–105

9/16

12

75–80

110–123

18

90–100

130–145

5/8

11

105–115

152–169

18

125–140

185–205

3/4

10

185–205

285–315

16

220–245

340–370

7/8

9

300–330

440–490

14

340–380

510–565

1

8

440–490

685–735

12

530–570

790–8665

1–1/8

7

620–690

935–1040

12

750–830

1115–1240

1–1/4

7

890–990

1250–1360

12

1040–1160

1600–1750

1–3/8

6

1160–1290

1745–1940

12

1420–1580

2125–2360

1–1/2

6

1570–1740

2300–2600

12

1800–2000

2600–3020

THREADS

PER

INCH

TORQUE VALUES (LB./FT.)

MEDIUM CARBON

(SAE GRADE 5)

ALLOY STEEL

(SAE GRADE 8)*

BOLT

DIAM.

E–38274

(For Lubricated Bolts)

Diameter

Refer to the DATA section for the Minimum Permissi-

ble Commutator Diameter dimension. If the commutator

brush–surface diameter will be less than the minimum

permissible diameter after resurfacing operations are

performed, replace the commutator before the new ar-

mature coils are assembled.