5 lp gas fuel system – Generac PRIMEPACT 50 04164-3 User Manual

Page 30

28

2.4.2 GENERATOR FUEL SUPPLY LINE

2.4.2.1 Rigid Fuel Lines

Those lines used to supply fuel from a tank to the generator must

comply with applicable codes, standards and regulations. The fol-

lowing general rules apply to rigid fuel lines:

Rigid lines should be of annealed, seamless, drawn aluminum

•

or steel.

Lines and fittings must comply with SAE J512F, “Standard

•

Automotive Fittings,” or with ANSI B126.26 (latest edition).

Route the fuel line so that at least 2 inches (51 mm) of clear-

•

ance is maintained between the line and any exhaust system

parts.

Do not attach electrical wiring to fuel lines. Route the wiring so

•

it cannot come into contact with any fuel line.

Route fuel lines so if they leak, fuel does not drip onto any

•

electrical or exhaust system parts.

Use nonferrous metal straps without sharp edges to secure

•

fuel lines.

2.4.2.2 Flexible Fuel Line

Use an approved flexible length of fuel hose between the generator

fuel inlet connection and rigid fuel lines. This prevents breaking of

the line caused by vibration, shifting, settling or movement. The

following rules apply:

The flexible hose must comply with SAE J1737 (30R7),

•

“Standard for Fuel and Oil Hose.” It must be approved for use

with gasoline and low permeability.

The hose should be at least 6 inches (152 mm) longer than

•

is needed to prevent the hose from rupturing if the generator

shifts or settles.

2.5 LP GAS FUEL SYSTEM

DANGER

LP gas is highly EXPLOSIVE. The gas is heavier

than air and tends to settle in low areas. Even

the slightest spark can ignite it and cause and

explosion. Only competent, qualified people

should be allowed to install, test, adjust or ser-

vice an LP gas fuel system. Install the optional

fuel system in compliance with applicable codes,

standards and regulations. After the installation,

do not do anything that might render the system

in noncompliance with applicable codes and

standards.

The LP powered range of generators are fitted with a nonadjust-

able, factory set system. These systems are tamper-proof to meet

1997 California Air Resources Board requirements for engine

emission.

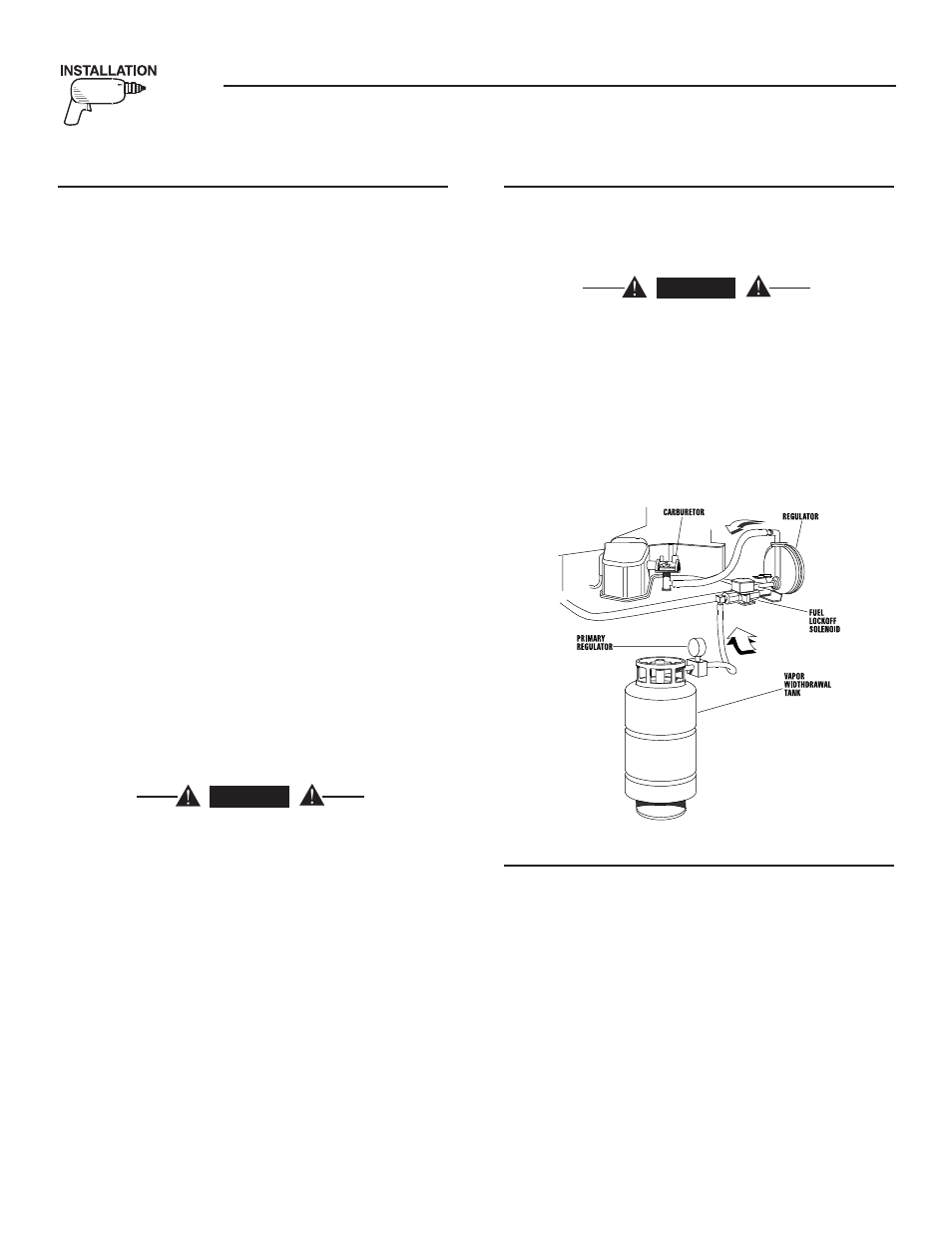

2.5.1 PARTS NOT INCLUDED IN FUEL SYSTEM

The propane fuel system does NOT include such items as (a) gas

tank, (b) gas piping, (c) fittings, (d) valves, and (e) primary regula-

tor, used to store the gaseous fuel and deliver it to the gaseous fuel

solenoid (Figure 2.15).

DANGER

Use only approved components in the fuel sup-

ply system. All components must be properly

installed in accordance with applicable codes.

Improper installation or use of unauthorized

components may result in fire or an explosion.

Follow approved methods to test the system for

leaks. No leakage is permitted. Do not allow fuel

vapors to enter the vehicle interior.

Figure 2.15 – Typical Propane Gas Fuel System

2.5.2 SOME IMPORTANT CONSIDERATIONS

When installing an LP gas system, consider seriously the following

items:

All fittings, lines, hoses and clamps must be tight and free of

•

leaks. Apply a pipe sealant to threads when assembling thread-

ed connections. This reduces the possibility of leakage.

Test the entire fuel system for leaks using approved test meth-

•

ods.

Optimum gas pressure at the inlet to the gaseous fuel solenoid

•

valve and secondary regulator is 11 inches water column.

The installer’s fuel supply connection point is at the gaseous

•

fuel solenoid valve. This is a 3/4-inch (female) connection.

Provide a suitable 3/4-inch NPT (male) connector to attach to

the fuel supply line.

Use a length of approved flexible fuel hose between the gaseous

•

fuel solenoid valve and rigid gas piping. The flexible line should

be at least six (6) inches longer than necessary.

Section 2 – Installation

Recreational Vehicle Generator