Troubleshooting, Motor & electrical – Grizzly G1007 User Manual

Page 39

BdYZa<&%%+$<&%%,B[\#H^cXZ.$%.

"(,"

GZk^Zli]ZigdjWaZh]ddi^c\VcYegdXZYjgZh^ci]^hhZXi^dc^[VegdWaZbYZkZadehl^i]ndjgbVX]^cZ#>[ndj

cZZYgZeaVXZbZcieVgihdgVYY^i^dcVa]Zael^i]VegdXZYjgZ!XVaadjgIZX]c^XVaHjeedgiVi*,%*)+".++(#

Note:

Please gather the serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

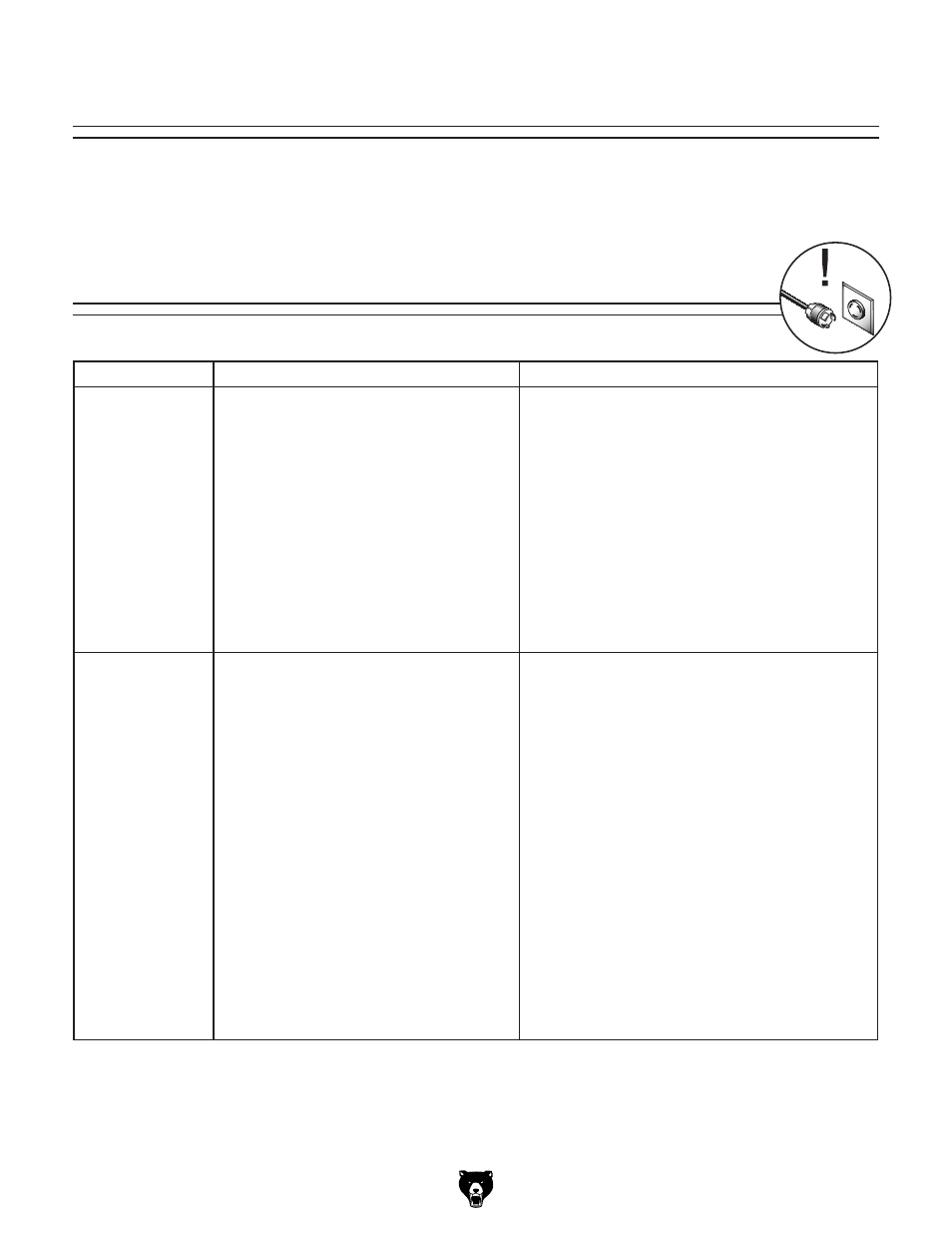

Motor & Electrical

Hnbeidb

Edhh^WaZ8VjhZ

Edhh^WaZHdaji^dc

Machine does not

start or a breaker

trips.

1. Plug/receptacle is at fault or wired

incorrectly.

2. Motor connection wired incorrectly.

3. Wall fuse/circuit breaker is blown/tripped.

4. Overload relay has tripped.

5. Power supply switched OFF or is at fault.

6. Wiring is open/has high resistance.

7. Main power switch is at fault.

8. Motor is at fault.

1. Test for good contacts; correct the wiring.

2. Correct motor wiring connections.

3. Ensure circuit size is suitable for this machine;

replace weak breaker.

4. Reset overload relay.

5. Ensure power supply is switch on; ensure

power supply has the correct voltage.

6. Check for broken wires or disconnected/

corroded connections, and repair/replace as

necessary.

7. Replace faulty ON/OFF switch.

8. Test/repair/replace.

Machine stalls or is

underpowered.

1. Feed rate/cutting speed too fast for task.

2. Workpiece alignment is poor.

3. Wrong workpiece material.

4. Motor connection is wired incorrectly.

5. V-belt(s)

slipping.

6. Plug/receptacle is at fault.

7. Motor bearings are at fault.

8. Machine is undersized for the task.

9. Motor has overheated.

10. Contactor not getting energized or

has poor contacts.

11. Spindle rotation switch at fault.

12. Motor is at fault.

1. Decrease feed rate/cutting speed.

2. Eliminate workpiece binding; use jig or clamps

and position table properly for workpiece

alignment control.

3. Use metal with correct properties for your type

of machining.

4. Correct motor wiring connections.

5. Replace

bad

V-belt(s).

6. Test for good contacts; correct the wiring.

7. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

8. Use smaller sharp cutters/drill bits; reduce the

feed rate; reduce the spindle RPM; use cutting

fluid if possible.

9. Clean off motor, let cool, and reduce workload.

10. Test for power on all legs and contactor

operation. Replace if faulty.

11. Test/repair/replace switch.

12. Test/repair/replace motor.