Determining proper fluid temperature – Graco VISCON HP 309524L User Manual

Page 12

Installation

12

309524L

Determining Proper Fluid

Temperature

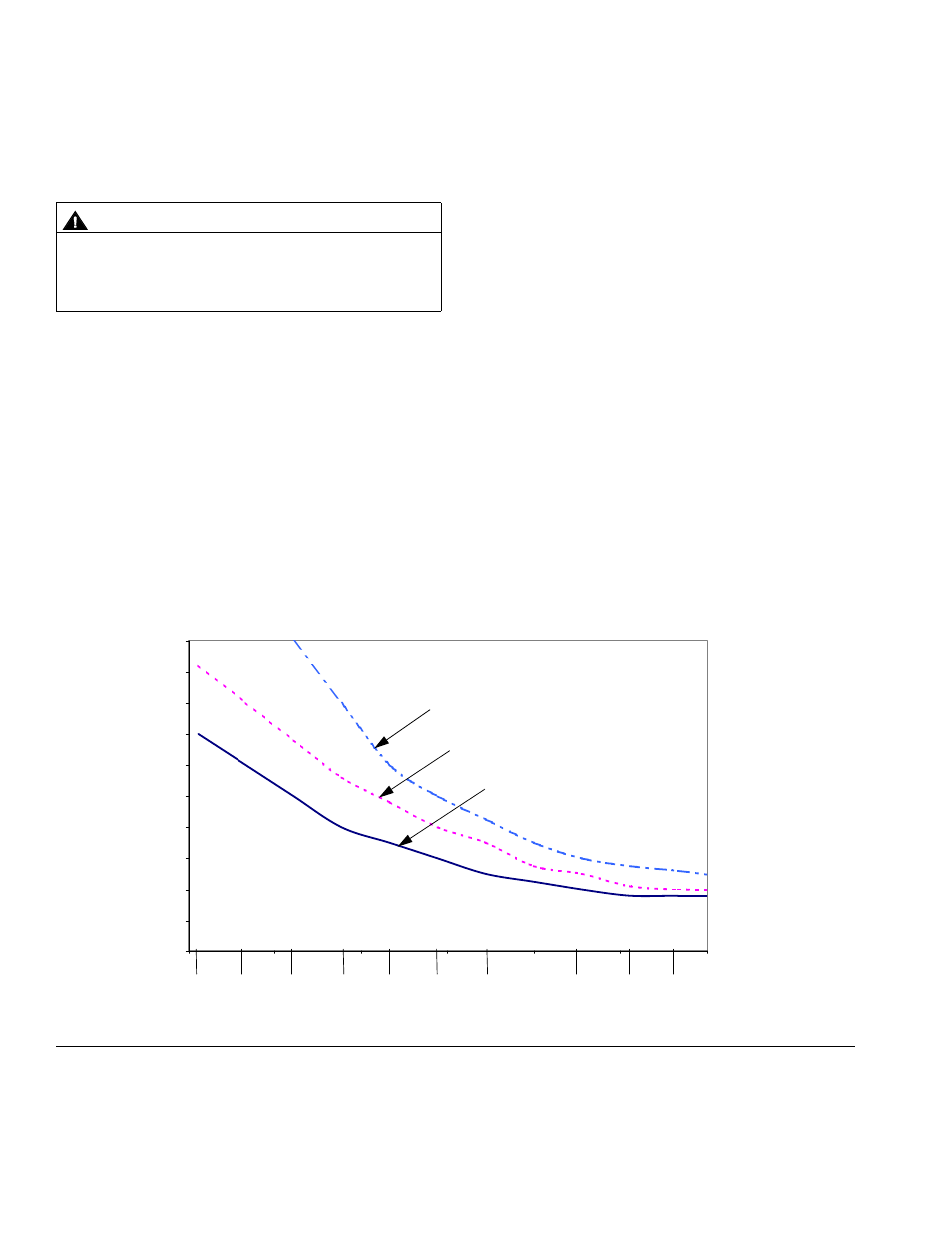

Use the lowest temperature setting possible for maxi-

mum heater life. Use the chart in F

. 9 to determine the

Under-Boil

®

temperature. F

. 9 also shows the effect of

temperature on reducing viscosity. Note that most of the

viscosity reduction occurs by 130°F (55°C).

Under-Boil is the Graco method of hot, airless spraying

where the fluid is heated to a temperature just under the

boiling point of its most volatile solvent.

To find your fluid’s Under-Boil temperature:

1.

Pour a small sample into a heat-proof container.

2.

Measure and record the fluid temperature and vis-

cosity using a No. 2 Zahn cup.

3.

Heat water in a large container to 200°F (93°C).

Place the sample in the water.

4.

At every 10° temperature rise, measure and record

the viscosity and temperature. Do this until solvents

start boiling off and the viscosity starts to level off,

usually 160-170°F (71-77°C).

5.

To find the temperature to use in your Under-Boil

system:

a.

Subtract the lowest viscosity reading from the

highest one.

b.

Multiply the result by 0.90.

c.

Subtract the result from the highest viscosity

reading. Find this number on your temperature

and viscosity records.

CAUTION

Operating the heater at its highest setting, over 180°F

(82°C), for long periods of time decreases the heater

life and can cause fluid to dry out; which can clog the

heater and result in a poor finish.

F

IG

. 9: Reducing Viscosity: Under-Boil Method

0

10

20

30

40

50

60

70

80

90

100

20

30

40

50

60

70

80

o

C

(70)

(

o

F)

(80)

(90)

(100)

(110)

(120)

(130)

(140)

(150)

(160)

(170)

(180)

Visc

osity: seco

nd

s with #2

Zah

n

cu

p

Temperature

Heavy Lacquer

Medium Lacquer

Enamel