Goodman Mfg CPG SERIES User Manual

Page 15

15

Three Phase Models

3) PERCENT VOLTAGE

UNBALANCE

2) MAXIMUM VOLTAGE DEVIATIONS

FROM AVERAGE VOLTAGE

1) AVERAGE VOLTAGE

HOW TO USE THE FORMULA:

EXAMPLE: With voltage of 220, 216, and 213

1) Average Voltage = 220+216+213=649 / 3 = 216

2) Maximum Voltage Deviations from Average Voltage = 220 - 216 = 4

3) Percent Voltage Unbalance = 100 x

=

= 1.8%

Percent voltage unbalance MUST NOT exceed 2%

.

4

216

400

216

= 100 X

F

IELD

D

UCT

C

ONNECTIONS

Verify that all duct connections are tight and that there is no

air bypass between supply and return.

C

ONTROL

V

OLTAGE

C

HECK

With disconnect switch in the open “OFF” position, discon-

nect blue wire from low voltage transformer TRANS1. Close

the disconnect switch to energize TRANS1 control trans-

former. Check primary and secondary (24V) of control trans-

former TRANS1.

T

HERMOSTAT

P

RELIMINARY

C

HECK

With disconnect switch open and blue wire disconnected from

TRANS1 transformer, attach one lead of ohmmeter to termi-

nal R on TB1 terminal block. Touch, in order, the other ohm-

meter lead to terminals Y1, Y2 and G at TB1 terminal block.

There must be continuity from terminal R to terminals Y and

G. R to Y indicates cool. R to G indicates fan (auto). Replace

blue wire on TRANS1 transformer.

F

ILTER

S

ECTION

C

HECK

Remove filter section access panels and check that filters

are properly installed. Note airflow arrows on filter frames.

B

EARING

C

HECK

Prior to energizing any fans, check and make sure that all

setscrews are tight so that bearings are properly secured to

shafts.

S

ET

E

VAPORATOR

F

AN

R

PM

Actual RPM’s must be set and verified with a tachometer or

strobe light. Refer to Appendices A and B for basic unit fan

RPM. Refer also to “Airflow” section of this manual. With

disconnect switch open, disconnect thermostat wires from

terminals Y and W. This will prevent heating and mechanical

cooling from coming on. Place a jumper wire across termi-

nals R and G at TB1 terminal block. Close disconnect switch;

evaporator fan motor will operate so RPM can be checked.

For gas heat units, the airflow must be adjusted so that the

air temperature rise falls within the ranges given stated on

Data Plate (see Appendix A - Blower Performance).

T

ENSION

AND

A

LIGNMENT

A

DJUSTMENT

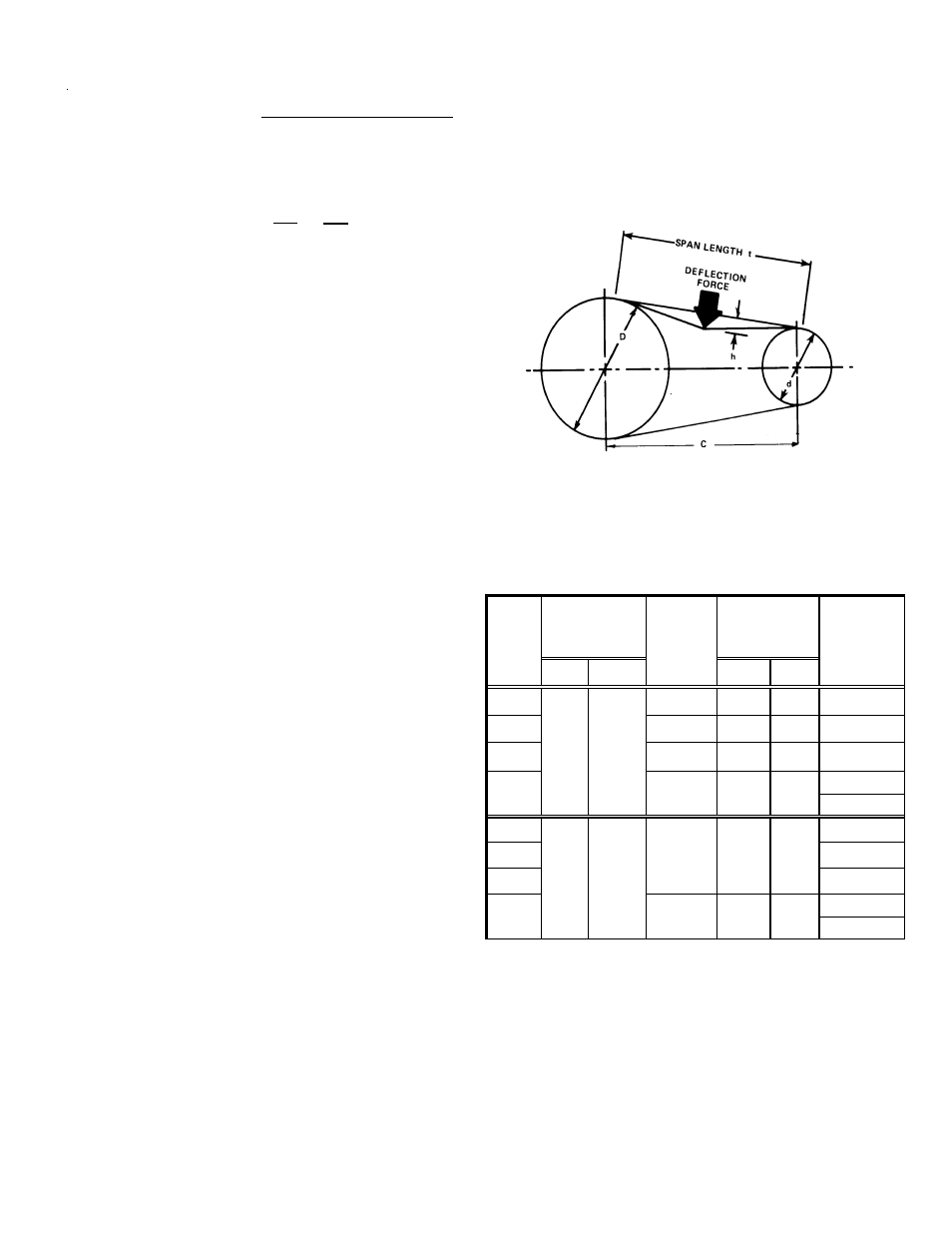

Correct belt tension is very important to the life of your belt.

Too loose a belt will shorten its life; too tight, premature mo-

tor and bearing failure will occur. Check you belt drive for

adequate “run-in” belt tension by measuring the force required

to deflect the belt at the midpoint of the span length. Belt

tension force can be measured using a belt tension gauge,

available through most belt drive manufacturers.

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

DRIVE BELT TENSION ADJUSTMENT

BELT

DRIVE

Used

New

7.5 Ton

2.6 to 3.6

4.5 ± .5 5.5 ± .5

1/4 ± 1/16

8.5

2.6 to 3.6

4.5 ± .5 5.5 ± .5

1/4 ± 1/16

10 Ton

3.0 to 4.0

4.5 ± .5 5.5 ± .5

1/4 ± 1/16

1/4 ± 1/16

1/4 ± 1/16

7.5 Ton

1/4 ± 1/16

8.5

1/4 ± 1/16

10 Ton

1/4 ± 1/16

1/4 ± 1/16

1/4 ± 1/16

12.5 Ton

A, AX

High

Static

3.6 to 4.6

4.9 ± .5 6.0 ± .5

12.5 Ton

2.6 to 3.6

4.5 ± .5 5.5 ± .5

3.0 to 4.0

4.5 ± .5 5.5 ± .5

A, AX Standard

MODEL

DEFLECTION

(in)

DEFLECTION

FORCE (lbs)

SHEAVE

DIAMETER

(in)

TYPE

RECOMMENDED POUNDS OF FORCE PER BELT

The correct deflection force is 5 Ibs. for a new belt and 3.5

Ibs. for a belt that has been run in. New belt tension includes

initial belt stretch. When new V-belts are installed on a drive

the initial tension will drop rapidly during the first few hours.

Check tension frequently during the first 24 hours of opera-

tion. Subsequent retensioning should fall between the mini-

mum and maximum force. To determine the deflection dis-

tance from the normal position, use a straightedge or stretch

a cord from sheave to sheave to use as a reference line. On

multiple belt drives, an adjacent undeflected belt can be used

as a reference.