Cutting an extremely narrow workpiece, Making bevel cuts, Making cross cuts – Global Machinery Company REDEYE LS250TS2000W User Manual

Page 17: Replacing the saw blade

17

Cutting an extremely narrow workpiece

Longitudinal cuts in an extremely narrow workpiece with a

width of 30mm or less must always be made with the help

of a push block.

This table saw is not supplied with a push block. (Either

make or purchase a suitable one from a specialist dealer).

Warning.

Worn push blocks must be replaced without delay.

Making bevel cuts

1. Always use the fence when cutting bevels.

2. Set the saw blade to the required angle using the blade

angle wheel (21).

3. Set the fence to suit the width and height of the

workpiece using the laser line as a guide.

4. Carry out the cut in accordance with the workpiece width.

Making cross cuts

Warning.

When cross cutting, do not use the rip fence

(14) as a length stop as the cut off piece could bind

between the fence and the blade and cause kickback.

1. Push the mitre gauge (17) into one of the two slots of

the table saw and set it to the required angle. If you

also want to set the saw blade at an angle, use the

slot, which prevents your hand and the mitre gauge

coming into contact with the saw blade.

2. Press the workpiece firmly against the mitre gauge.

3. Switch on the saw.

4. Push the mitre gauge and the workpiece toward the saw

blade in order to make the cut.

Important.

Always hold the guided part of the workpiece.

Never hold that part of the workpiece, which is being cut

off. Always push the mitre gauge far enough forward for

the workpiece to be cut through completely.

5. Switch off the saw again.

6. Wait for the saw blade to stop before removing the

off-cuts.

Replacing the saw

blade

Warning.

Switch off the table

saw and remove the mains

power plug before carrying out

any adjustments, maintenance

work or blade changes. Wear

work gloves when handling

or fitting the blade.

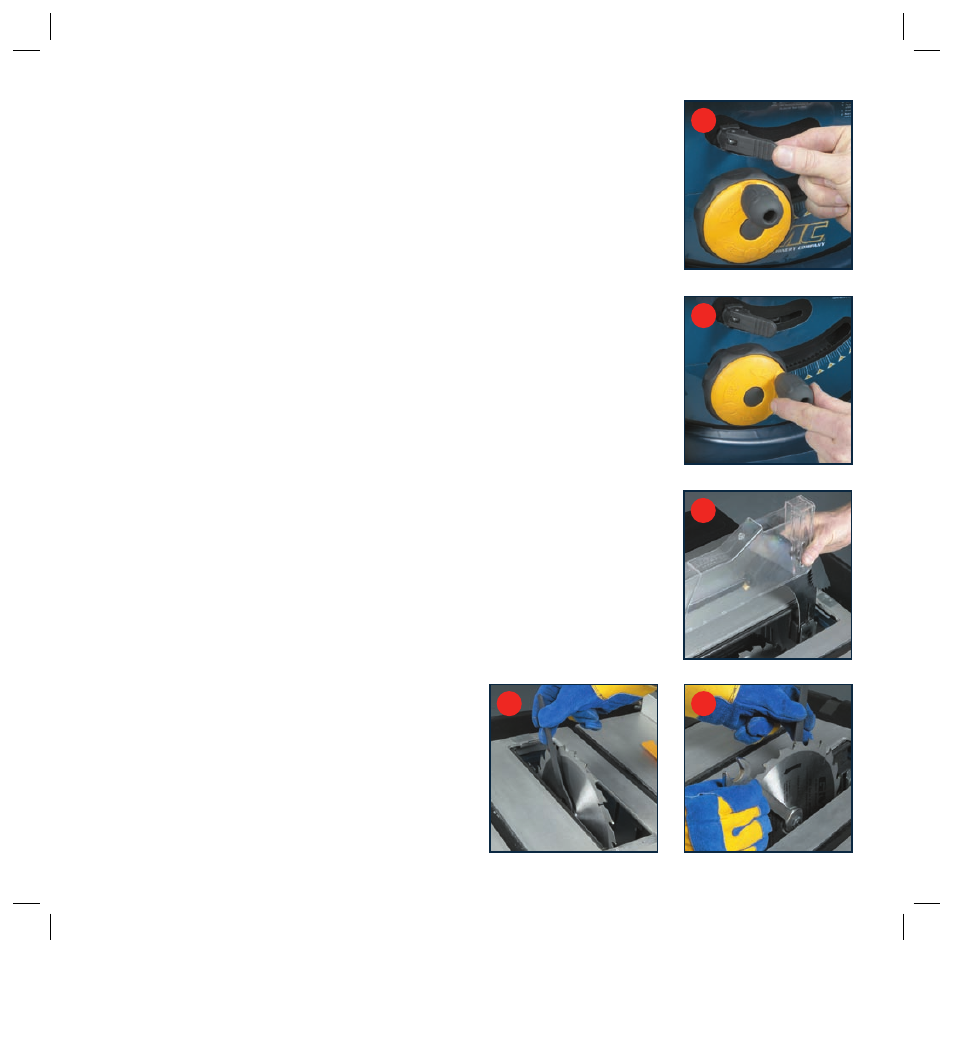

1. Loosen the blade lock (24)

(fig l) and turn the blade

height handle (20) (fig m)

until the saw blade is at its

maximum height.

2. Loosen and remove the

screw securing the table

insert (13).

3. Take out the table insert (13).

4. Remove the riving knife

(8) (fig n).

5. Use the spanner supplied

to lock the spindle in

position (fig o).

6. Use an 18mm open-ended

spanner (not supplied)

to undo the blade bolt

by turning it in an

anti-clockwise direction

(right-hand thread)(fig p).

m

n

o

p

l