Grizzly T21888 User Manual

Page 19

model t21888 (mfg. since 2/10)

-

17

-

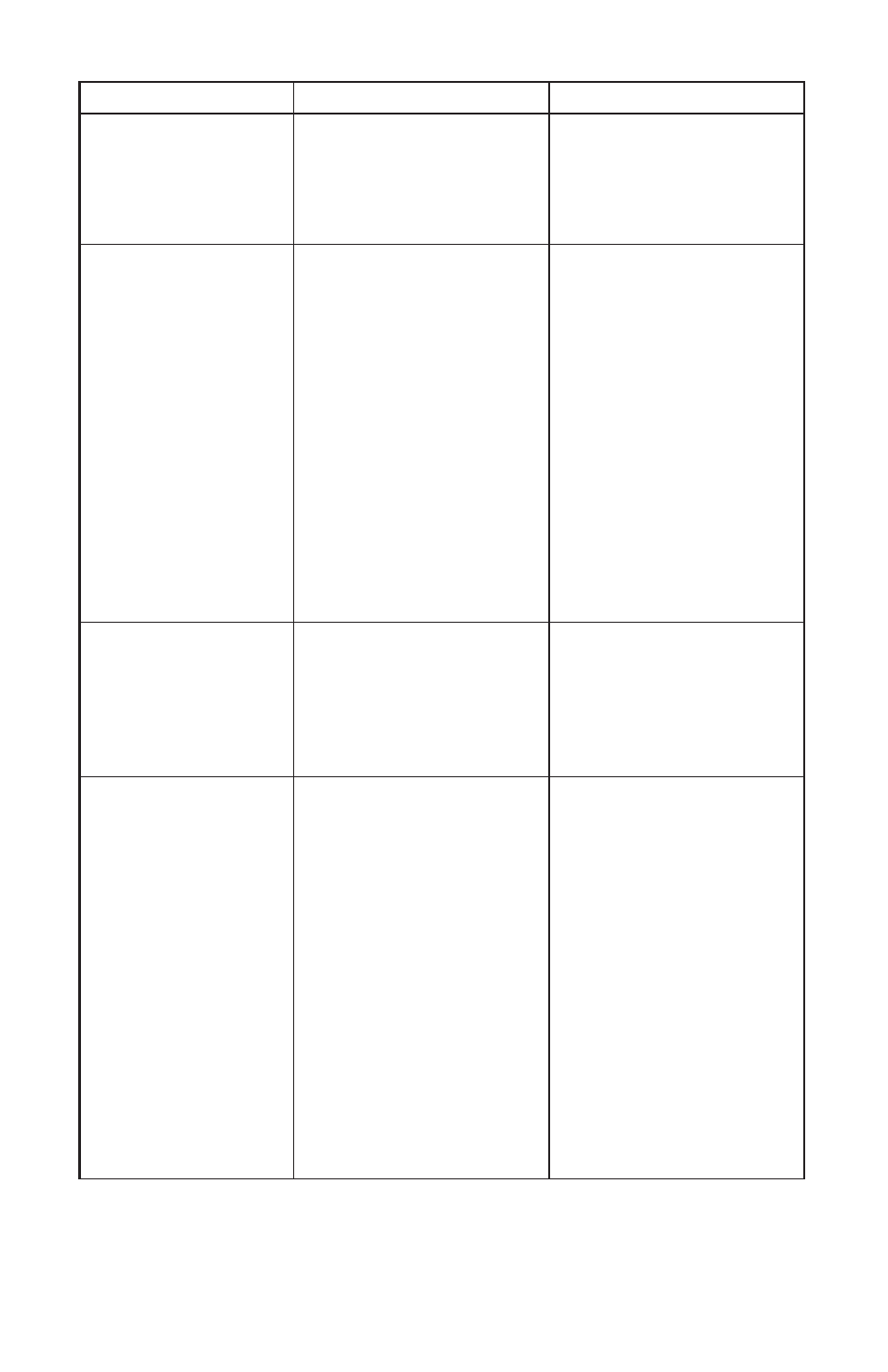

symptom

possible cause

possible solution

Air is dirty or has exces-

sive moisture.

1. tank is not drained.

2. delivery pipes are dirty.

1. open drain valve and

make certain all the water

is drained out.

2. remove delivery pipes,

clean out and replace.

Air tools have oily dis-

charge.

1. Compressor tank need

draining.

2. Compressor crankcase is

over full with oil.

3. in-line oiler is out of

adjustment (if used).

4. in-line filter is damaged

or missing (if used).

5. incorrect viscosity of oil

in the crankcase.

6. Compressor is at fault.

1. drain compressor tank

(

page 14).

2. drain and return oil level

to normal (

page 8).

3. Adjust in-line oiler drip

ratio or use correct vis-

cosity oil for in-line oiler.

4. replace filter or in-line

filter assembly.

5. Crankcase oil is too light,

replace with actual com-

pressor oil.

6. Worn compressor piston,

rings, or valves. rebuild

or replace compressor.

Air tools have watery

discharge or get cold

and freeze up with ice

during use.

1. Compressor tank needs

draining.

2. Ambient environment has

too much humidity.

3. in-line water separator is

full (if used).

1. drain compressor tank

(

page 14).

2. install in-line air dryer

and water separator.

3. drain water separator.

Compressor does not

build air pressure, or

does not reach full pres-

sure.

1. Air leaks in tanks or deliv-

ery pipes.

2. drain valve open.

3. Air filter clogged.

4. leaking check valve.

5. reed valves not sealing.

6. head gasket or valve

body gasket leaking.

7. Worn rings.

8. Broken crank shaft or

connecting rod.

1. Check air tanks, pipes

and all connections for

leaks.

2. Close drain valve.

3. inspect and clean air fil-

ter.

4. repair the check valve

(

page 18).

5. remove cylinder head

and replace reed valves.

6. remove head and

replace gaskets.

7. inspect and replace pis-

ton rings.

8. replace or rebuild com-

pressor.