Grizzly T21888 User Manual

Page 18

model t21888 (mfg. since 2/10)

-

16

-

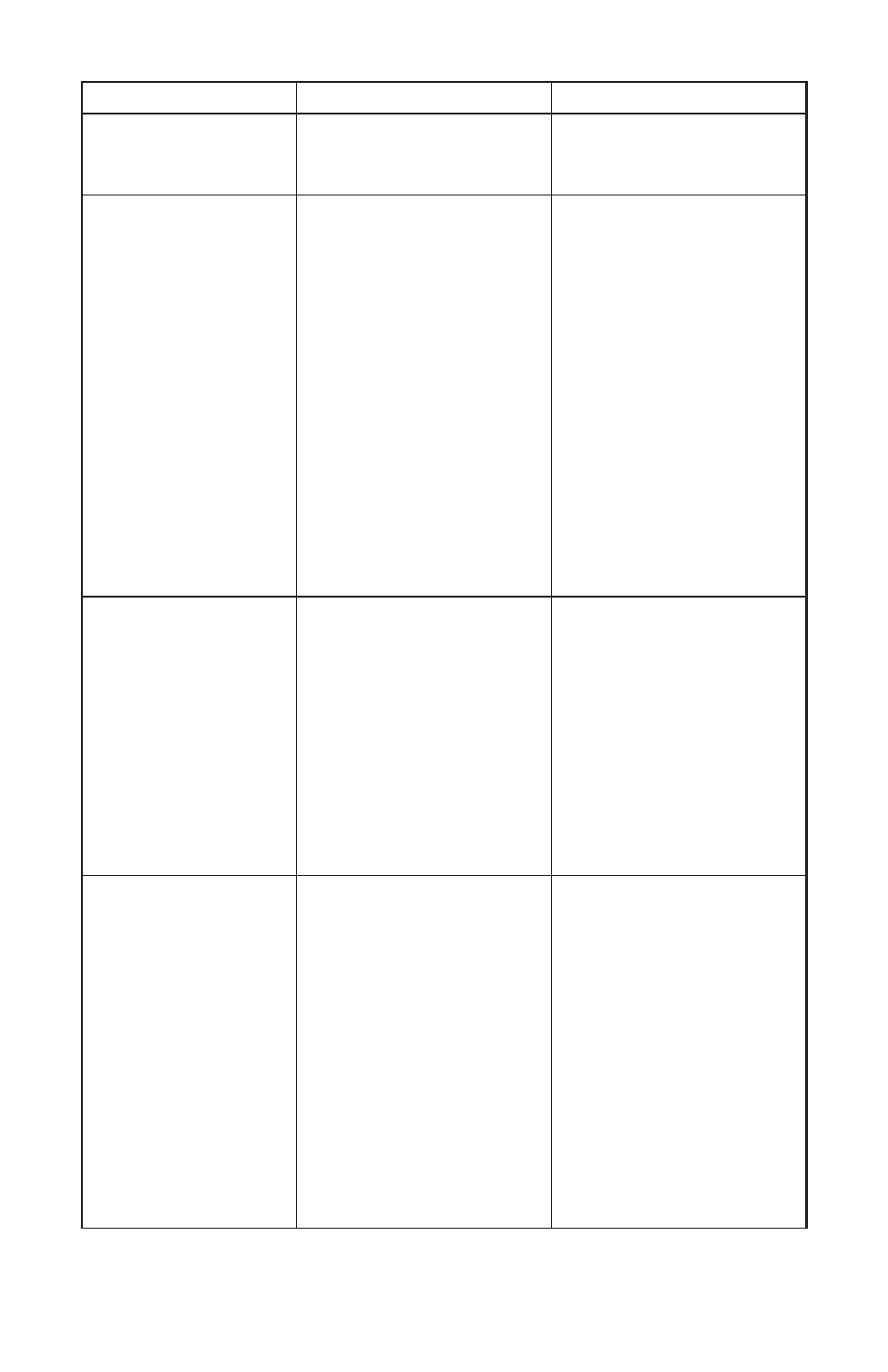

symptom

possible cause

possible solution

Air leaks from pressure

switch.

1. Faulty check valve.

2. Faulty pressure switch.

1. repair the check valve

(

page 18).

2. replace pressure switch.

low pressure at the

tank, or tank pressure

drops after compressor

is turned

OFF.

1. Air leaks in tanks or deliv-

ery pipes.

2. drain valve open.

3. Air filter clogged.

4. pressure switch turns the

motor

OFF too soon.

5. leaking check valve.

6. pressure relief valve

releasing below 110 psi.

7. gaskets leaking.

8. Worn rings.

1. Check air tank, pipes and

all connections for leaks.

2. Close drain valve.

3. inspect and clean air fil-

ter.

4. Adjust the pressure

switch (

page 20).

5. repair the check valve

(

page 18).

6. replace pressure relief

valve.

7. Check gaskets on cylin-

der head assembly, repair

or replace as needed.

8. inspect and replace pump

piston rings.

pressure relief valve

stays open and motor

won’t stop running.

1. pressure switch adjusted

too high.

2. Faulty pressure switch,

unit is trying to overpres-

sure the tank.

3. Faulty pressure relief

valve.

1. Adjust the pressure

switch (

page 20)

2. turn compressor oFF,

unplug from power sup-

ply, and empty tank.

do not UsE until switch

is replaced.

3. relief valve is reliev-

ing pressure too early.

replace pressure relief

valve.

Air tool has low supply

pressure but compres-

sor has sufficient air

pressure.

1. in-line filter is damaged

or clogged (if used).

2. in-line water separator is

full (if used).

3. pressure regulator.

4. Air leaks in hoses.

5. pressure gauge bad.

6. pressure switch turns the

motor

OFF too soon.

1. replace filter or in-line

filter assembly.

2. drain water separator.

3. Adjust pressure regula-

tor, if no improvement,

inspect regulator for leaks

or replace.

4. Check air hoses and all

connections for leaks .

5. replace the pressure

gauge.

6. Adjust the pressure

switch (

page 20).