Non-ce standard for incoming gas pressures – Frymaster H52 Series User Manual

Page 9

2-4

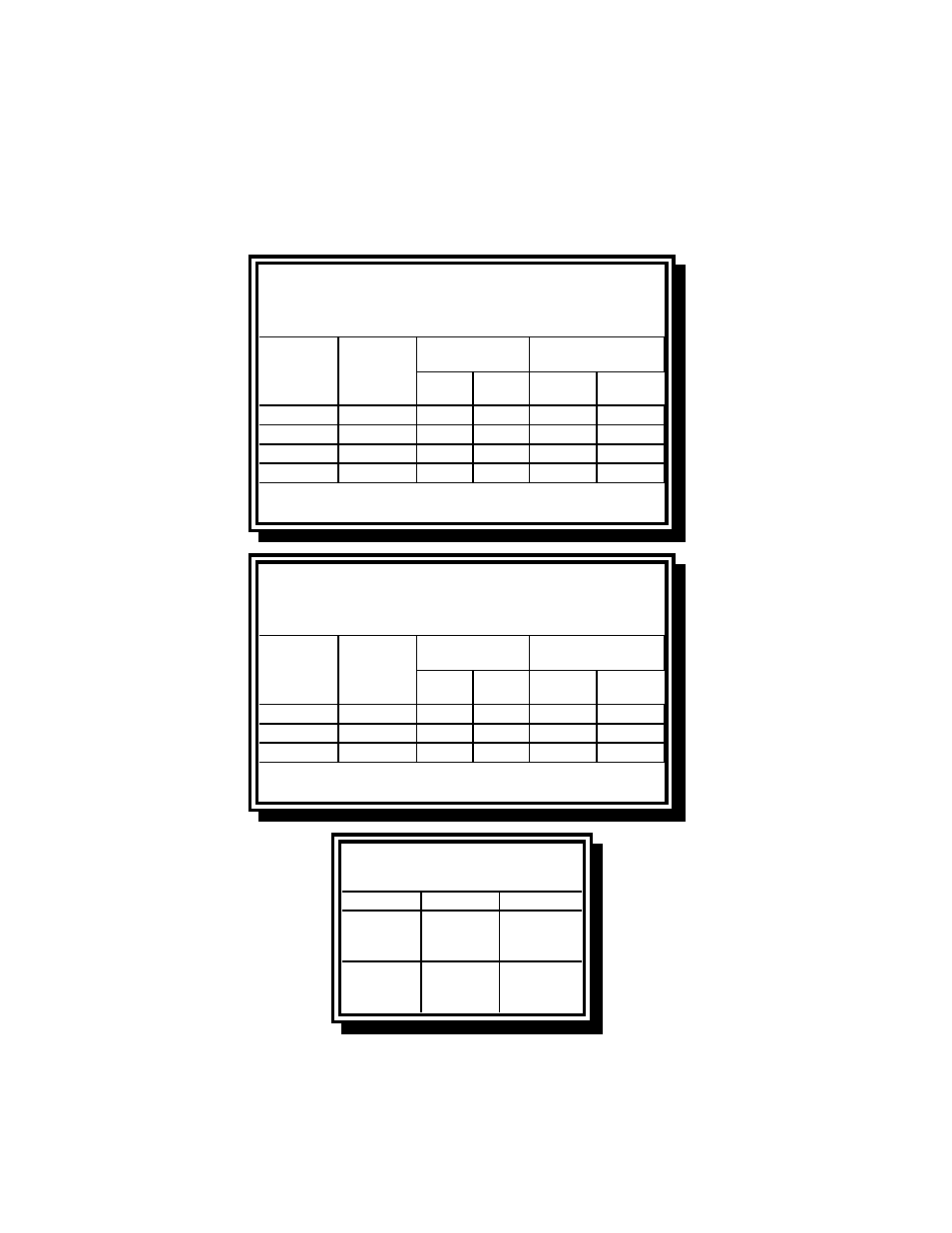

5. Refer to the data plate on the inside of the fryer door to determine if the fryer burner is config-

ured for the proper type of gas before connecting the fryer quick-disconnect device or piping

from the gas supply line.

6. Verify the minimum and maximum gas supply pressures for the type of gas to be used in accor-

dance with the accompanying tables.

Orifice Diameter

Single

Vat

Dual

Vat

Single

Vat

Dual

Vat

G20

20

2 x 3.40 2 x 3.40

7 mbar

6.5 mbar

G25

20 or 25

2 x 3.40 2 x 3.40

10 mbar

9 mbar

G30

28/30 or 50 2 x 2.05 2 x 2.05

17 mbar

17 mbar

G31

37 or 50

2 x 2.05 2 x 2.05

20 mbar

18.5 mbar

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured After April 1999

(1) mbar = 10.2 mm H

2

O

Gas

Pressure

(mbar)

(1)

Regulator Pressure

Orifice Diameter

Single

Vat

Dual

Vat

Single

Vat

Dual

Vat

G20

20

2 x 3.40 2 x 3.40

7 mbar

6.5 mbar

G25

20 - 25

2 x 3.40 2 x 3.40

10 mbar

9 mbar

G31

37 - 50

2 x 2.05 2 x 2.05 20.2 mbar 18.5 mbar

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured Through April 1999

(1) mbar = 10.2 mm H

2

O

Gas

Pressure

(mbar)

(1)

Regulator Pressure

Non-CE Standard

for Incoming Gas Pressures

Gas

Minimum

Maximum

Natural

6" W.C.

1.49 kPa

14.93 mbar

14" W.C.

3.48 kPa

34.84 mbar

LP

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

7. For fryers equipped with a FootPrint III system (BIH52 models), plug the electrical cord into a

power receptacle behind the fryer.