3 data-side servo data format, 4 spindle motor control – FUJITSU MAF3364FC User Manual

Page 54

C141-F037-02EN

5 - 15

5.7.3

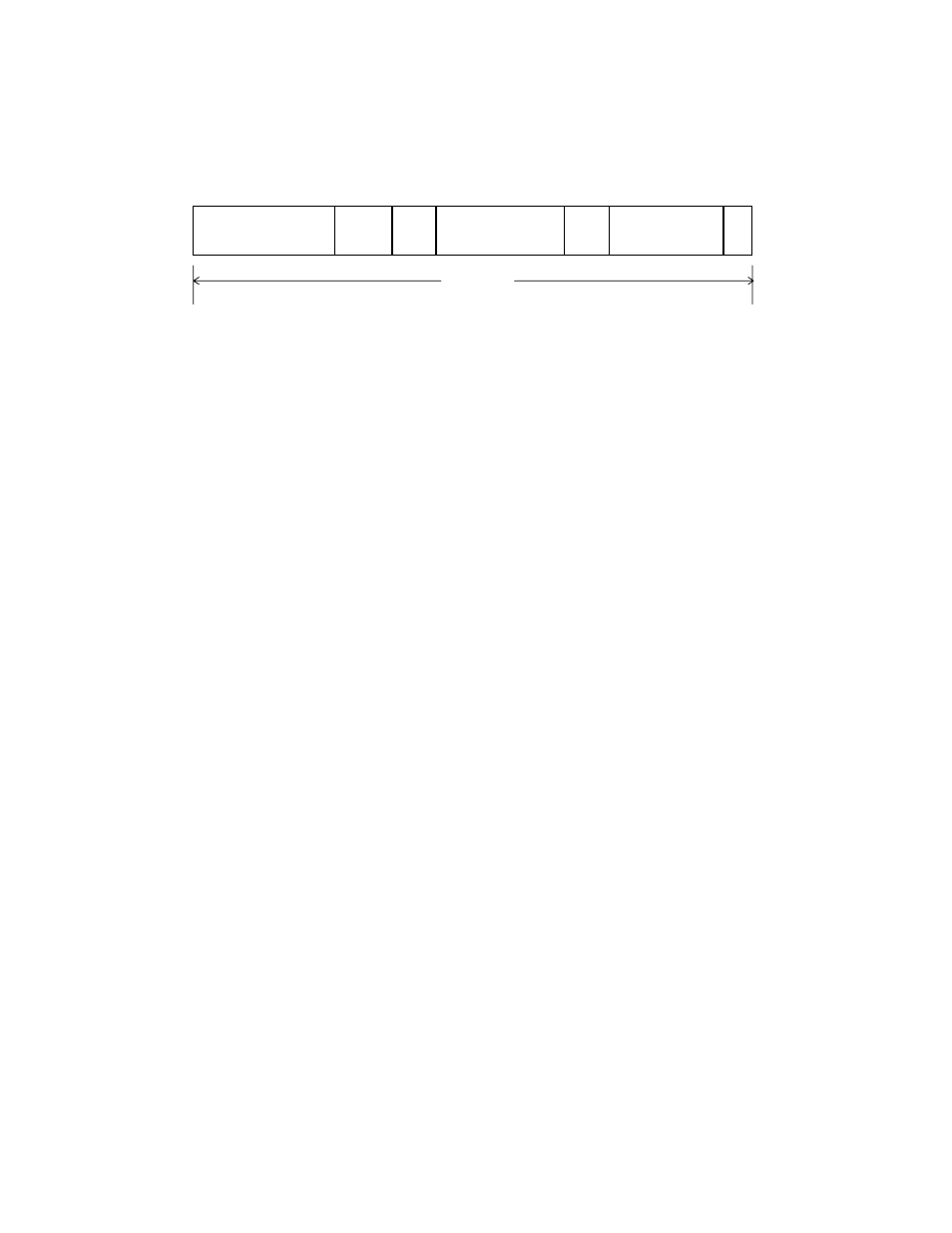

Data-side servo data format

Position

Gap

Gap

5,067

µ

s

Gray code

Gap

Servo

mark

W/R recovery

Figure 5.7

Servo frame

5.7.4

Spindle motor control

The FC control MCU controls the senseless 3-phase spindle motor. It carries out start / normal rotation

control in accordance with commands from the FC unit.

(1)

Activation

The FC control MCU carries out control of the spindle motor from the stopped condition to

normal rotation by the following sequence.

1) DSP intermittently supplies current between specific phases (e.g., phases U and V) to force a

fixed motor rotation position. This operation is called alignment.

2) In the next timing phase of 1) above, the DSP creates a rotating magnetic field. The motor

rotates from a low rotational frequency up to about 100 rpm. This is called synchronization

control.

3) When the motor reaches a high rotational frequency, a counterelectromotive voltage (back

EMF) is generated. This voltage tells the DSP the rotational frequency and angular position

of the motor. Using the rotation position detection data, the spindle controller supplies

current to the correct phase to rotate the motor. The MCU then detects the rotational

frequency, and the spindle controller accelerates the motor up to the steady-state angular

frequency.

(2)

Rotational speed control mode

When the activation mode terminates, the rotational speed control mode starts. The MPU

controls the controller to maintain the detected rotational speed.