6 gas inputs – Frymaster SM60 User Manual

Page 25

DEAN MILLIVOLT GAS FRYERS (NON-CE)

CHAPTER 3: INSTALLATION INSTRUCTIONS

3-9

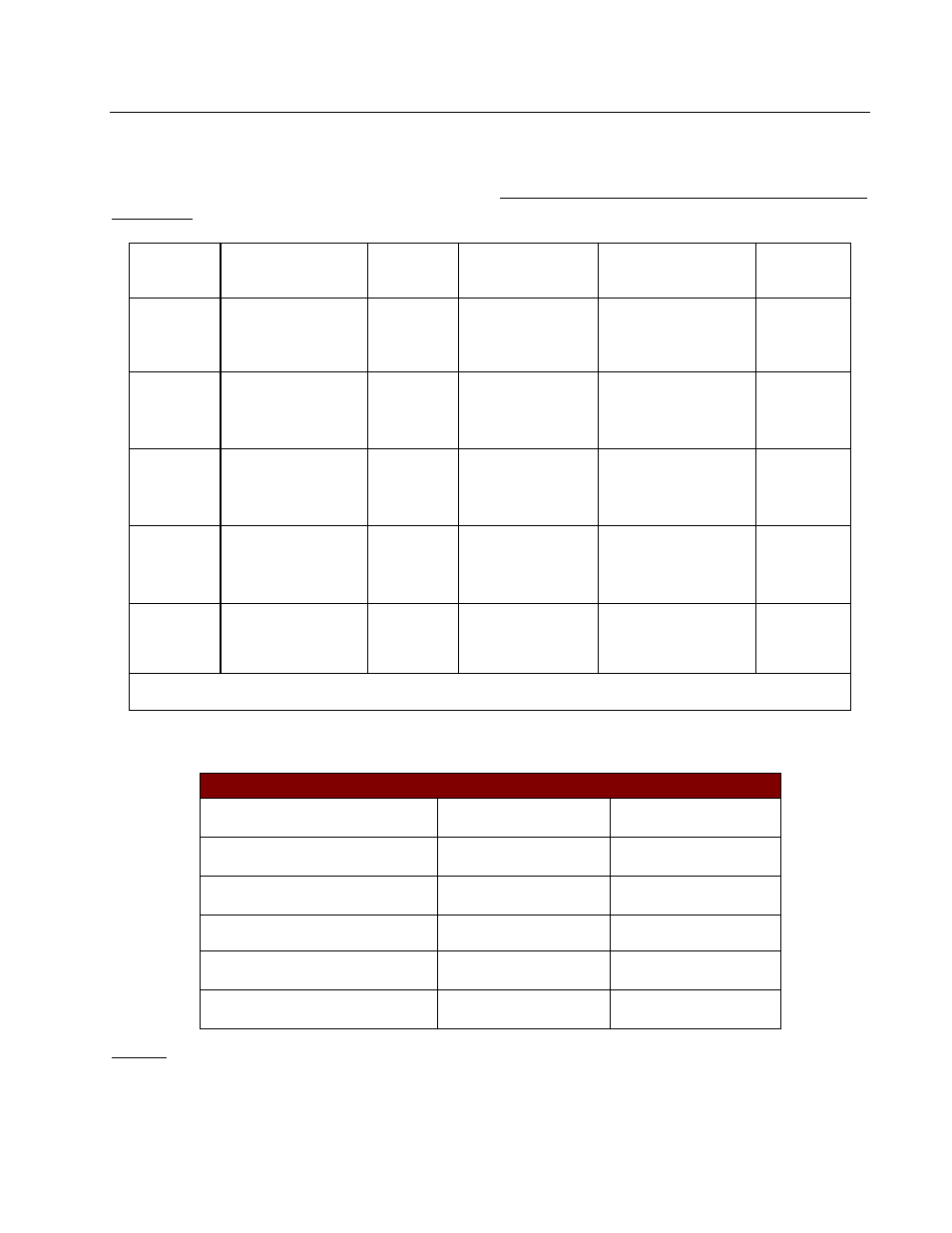

3.6 Gas Inputs

Nominal Heat Inputs (Qn), Gas Type, Orifice Size (applicable for fryer operation at altitudes of 2000

feet or less), Part Number and Quantity are listed in the table below:

MODEL NOMINAL

HEAT

INPUT- Qn

(BTU)

GAS TYPE

ORIFICE SIZE

(MM)

ORIFICE

PART NO.

ORIFICE

QUANTITY

SM 80 GM

165

NAT

LP

2.58(#38)

1.61(#52)

810-2062

810-2063

5

5

SM 60 GM

SR 62G

150

NAT

LP

LP

2.53(#39)

1.51(#53)

1.61(#52)**

810-2048

810-2059

810-2063**

5

5

5

SR 52 GM

SM 50 GM

120

NAT

LP

2.53(#39)

1.51(#53)

810-2048

810-2059

4

4

SM 35 GM

SR 42G

105

NAT

LP

2.80(#35)

1.70(#51)

810-2040/*810-3097

810-2064/*810-3099

3

3

SM 20 GM

50

NAT

LP

2.18(#44)

1.40(#54)

810-2050

810-2324

2

2

* Use these orifices on SR42 fryers built after 4/07.

** Use these orifices for Australian units.

A. Adjustments for different gases are as follows:

Gas Adjustments

Gas Type

Natural LP

Gas Supply Pressure*

4" W.C. (10 mbars)

11" W.C. (27.5 mbars)

Orifice Diameter

See Table Above.

See Table Above.

Burner Marking

None None

Pilot Marking

26N 16LP

Gas pressure at the regulator

[Inches W.C. (mbar)]*

4" W.C. (10 mbars)

11" W.C. (27.5 mbars)

NOTE: Outlet gas pressure must be adjusted strictly within the above requirements 5 to 10 minutes

after the appliance is operating.