Hull unit installation, Furuno electric co., ltd, Ab c d – Furuno DS-30 User Manual

Page 17

6

5

4

3

2

1

FURUNO ELECTRIC CO., LTD.

A

B

C

D

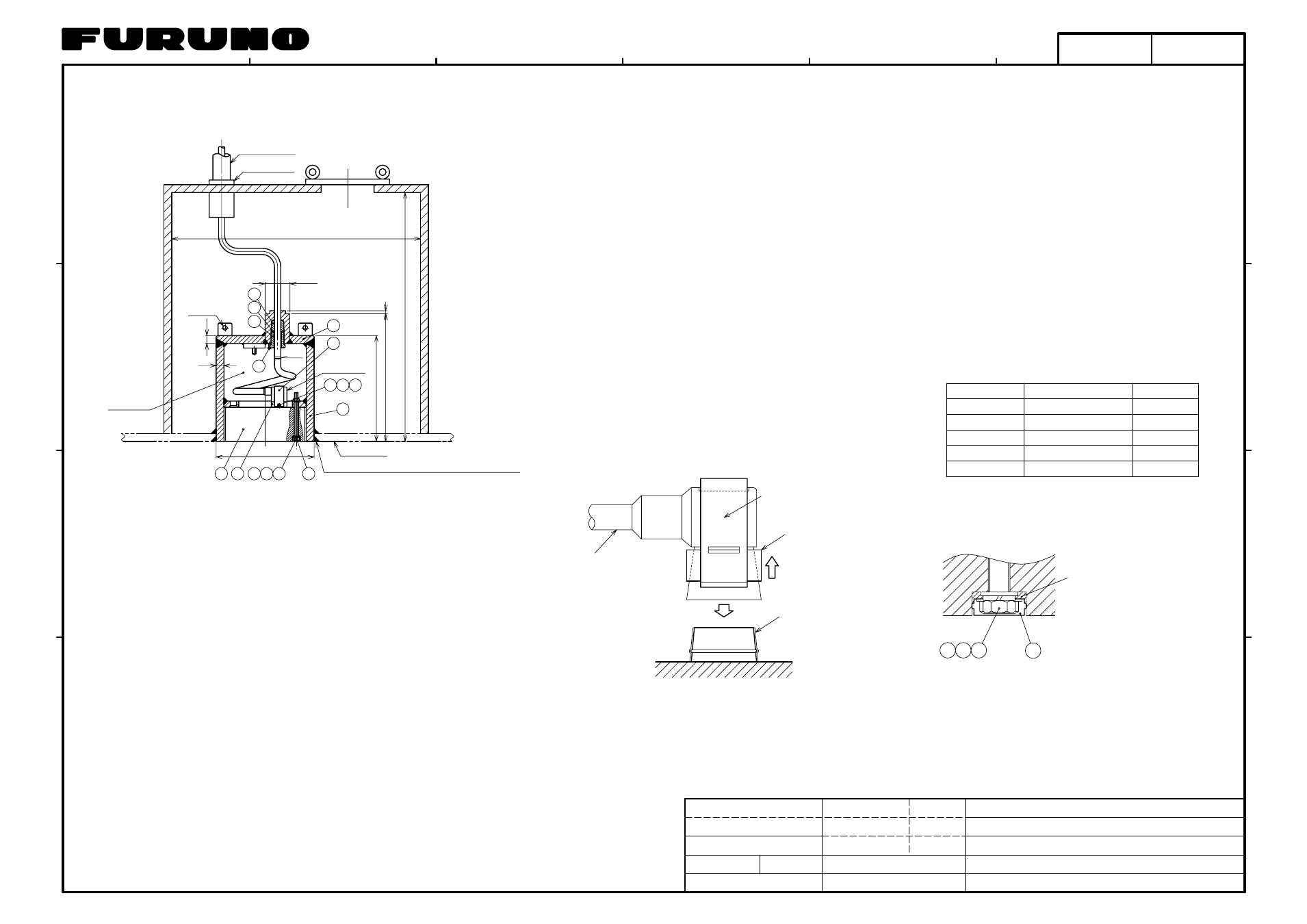

HULL UNIT INSTALLATION

⑥ Connector Holder

Ring

Silicone Grease

(Thine Coating)

Twisting the cable (namely, rotating the transducer by about one turn),

align the bow mark on the transducer with ship's bow and fix the transducer

450~550

450~550

0.5~3.0

0.5~3.0

0.5~3.0

STANDARD(Ω)

BEAM 2 (RED)

BEAM 3 (GRN)

TEST POINT

BEAM 1 (BLK)

TEMP SENSOR 1

TEMP SENSOR 2

TB #1(RED) - #2(BLK)

TB #4(RED) - #5(BLK)

TB #7(RED) - #8(BLK)

TB #10(YEL) - #11(WHT)

TB #13(BLU) - #14(GRY)

TYPE OF SIGNAL

Before starting the installation work, check that the transducer casing

is of a material approved by ship classification society concerned and

with a thickness not thinner than the hull plate. The standard tank

supplied by FURUNO is of material KSTPG370(KSTPG38,KST138), approved

by ship Classification Society of Japan, with a thickness of 25 mm.

Select the installation site reffering to the recommended sites described

in the installation instructions.

For ships prone to collect air bubbles under the hull bottom, consult

your local FURUNO office or agent for advice.

law because the transducer casing is waterproof. However it is recommended

shipyard may change as required. Since the transducer is detachable/

replaceable in water from outside the ship, maintenance space is not

required inside the compartment.

fore-aft line.

a) Fore/aft marks are engroved on the casing. Align them with ship's

φ315

5

2-φ15

10

2

7 8 9

25

25

15

3

4

φ80

800

800

340

410

10

11

12

1 14

13

CONDUIT PIPE

CABLE GLAND

CONNECTOR

WATERTIGHT

16

6

GROOVE DEPTH TO BE DETERMINED BY SHIPYARD.

(GRIND WELDING BUILD UP.)

HULL PLATE

※1

※1

LINE

Cable

Comfirm the ohm value of terminals on the transducer.

Do not use a megohmmeter.

A digital ohmmeter is recommended.

1) CHECKING MATERIAL AND THICKNESS OF TRANSDUCER CASING

2) DETERMINING INSTALLATION SITE

3) CONSTRUCTING WATERPROOF COMPARTMENT FOR TRANSDUCER CASING

4) WELDING CASING

6) FIXING TRANSDUCER

9) TESTING AFTER INSTALLATION

The compartment for the transducer casing is not compulsory required by

to construct it for safety. Dimensions shown above are only for reference;

b) Orientation and leveling errors can be offset on the data offset

Fore-aft orientation: Align the bow mark on the casing with ship's

Leveling: Install the casing so that the top face of the casing

is horizontal during navigation. Measure leveling accuracy with

fore-aft line to an accuracy within 1 degree.

a level meter, after the ship is launched.

c) Detach transducer (1), cable, cable gland (5) and gasket (3) before

d) Welding method for casing and ship's hull should be determined by the

considers them necessary.

shipyard. Weld reinforcement ribs to the casing if the shipyard

welding the casing.

menu in the display unit. Install the casing as follows.

e) Remove welding build up between the casing and the ship's hull (part

supplied.

c) Remove dirt and apply silicone grease onto the side of receptacle

on the transducer before plugging the watertight connector.

d) To plug in the watertight connector, pull up the ring and insert the

connector into the receptacle, and then fix the connector holder (6)

with hex nut (7).

Lay the cable from the casing to the transceiver unit

inside a conduit pipe and fill the conduit pipe with

sand or other appropriate materials to prevent cable

vibration.

Shop primer coating (Epcom Zinc Rich Primer B) has

been applied to the casing. Paint both inner and outer

b) Install locking bolt (15) after the cable gland is tightened.

a) Lead the transducer cable into the casing up to the white line mark on

the cable and tighten the cable gland with the cable gland spanner

marked ※1 in the drawing) with a grinder, for a flat finish.

5) FIXING/CONNECTING TRANSDUCER CABLE

8) PAINTING

7) CABLING

surfaces on the casing with the paint used for top

coating of the ship's hull bottom.

SEE NOTE2

NOTE 1: The transducer surface is coated with anti-

fouling paint Marine Star 20. Do not coat it by other

type of paint.

NOTE 2: The inside of transducer tank (16) and

It has no problem.

bolt(10)-thru hole will be filled with water.

10

11

12

DETAIL FOR FIXING BOLT AND BOLT CAP

13

kg

INSTALLATION PROCEDURE

DS-330/331

HULL UNIT

DS-30

E7236-Y10- J

Jul. 26 '06

Jul. 26 '06

T.TAKENO

T.YAMASAKI

CHECKED

APPROVED

DWG No.

DRAWN

SCALE

MASS

TITLE

REMARKS

NAME

by using hex bolt (10). After apply silicone sealant to bolt-head, put

SILICONE SEALANT

bolt cap (13) onto it.

2-6