Ductwork preparation, Indoor airflow data, Explanation of charts fresh air door – Friedrich 9 User Manual

Page 23

21

The Vert-I-Pak A series units must be installed with a free

return air configuration. The table below lists the indoor

airflow at corresponding static pressures. All units are rarted

at low speed.

The Vert-I-Pak units are designed for either single speed or

two fan speed operation. For single speed operation refer to

the airflow table below and select the most appropriate CFM

based on the ESP level. Connect the fan output from the

thermostat to the unit on either the GL terminal for low speed

or to the GH terminal for high speed operation.

For thermostats with two-speed fan outputs connect the low

speed output to the unit GL terminal and the high speed

output to the GH terminal.

Ductwork Preparation

Ductwork Preparation

Duct ESP:

Indoor Airflow Data

Pull the fl ex duct tight. Extra fl ex duct slack can greatly

increase static pressure

Explanation of charts

Fresh Air Door

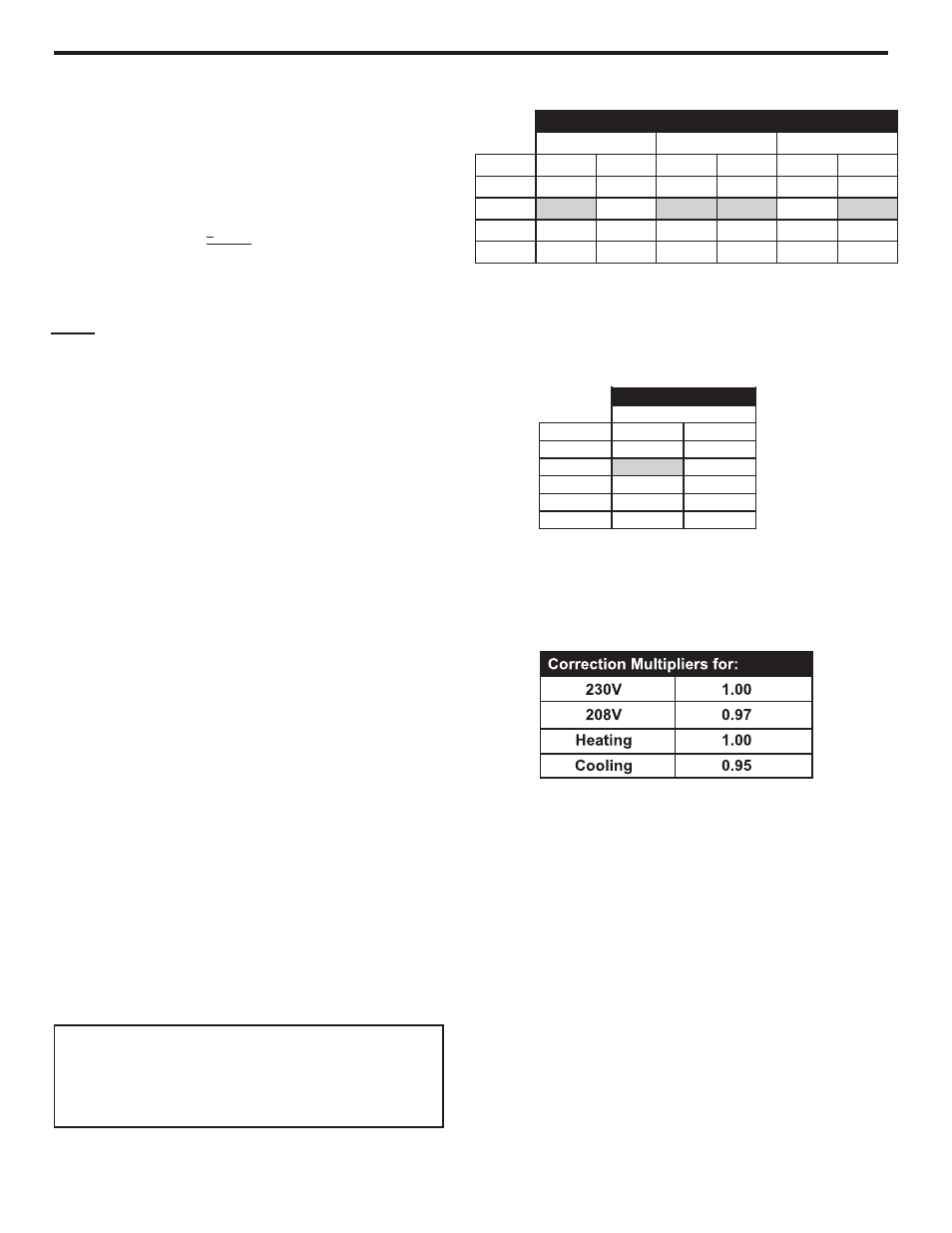

Chart A is the nominal dry coil VERT-I-PAK CFMs. Chart

B is the correction factors beyond nominal conditions.

To determine your system's indoor external static pressure

(ESP, in inches of water) use a duct calculator (as provided

by your duct supplier). Include all flex duct transitions and

discharge grille(s). If flex duct is used, be sure all the slack

is pulled out of the flex duct. Flex duct ESP can increase

considerably when not fully extended. DO NOT EXCEED a

total of .30 ESP, as this is the MAXIMUM design limit for the

VERT-I-PAK A-Series unit.

The Fresh Air Door is an “intake” system. The fresh air door

opened via a slide on the front of the chassis located just

above the indoor coil. Move the slide left to open and right

to close the fresh air door. The system is capable of up to 60

CFM of fresh air @ ~.3” H20 internal static pressure.

Determining the Indoor CFM: Chart A – CFM

Correct CFM (if needed):

Chart B – Correction Multipli

ers

Model

VEA12/VHA12

VEA18/VHA18

VEA09/VHA09

ESP (")

.00"

.10"

.20"

.30”

Low

340

300

230

140

High

385

340

280

190

Low

420

350 *

290

250

High

470

420 **

350

300

Low

430

400

340

290

High

480

450

400

330

Highlighted values indicate rated performance point.

Rated performance for

*

VEA12

Rated Performance for

** VHA12

ESP (")

Low

High

.00"

690

740

.10"

610

700

.20"

560

640

.30"

510

580

.40"

450

520

Model

VEA24/VHA24

Highlighted values indicate rated performance point.

IMPORTANT: FLEX DUCT CAN COLLAPSE AND

CAUSE AIRFLOW RESTRICTIONS. DO NOT

USE FLEX DUCT FOR: 90 DEGREE BENDS, OR

UNSUPPORTED RUNS OF 5 FT. OR MORE.

EXAMPLE: Measured voltage to unit (heaters) is 230 volts.

Measured Current Draw of strip heaters is 11.0 amps.

230 x 11.0 = 2530

2530/1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

Supply Air

95

°

F

Return Air

75

°

F

Temperature Rise

20

°

20 x 1.08 = 21.6

8635

= 400 CFM

21.6

- 7,200 BTU Packaged Terminal Air Conditioner Warranty 920-087-09 (12/10) 24,000 BTU/h A-SERIES ZoneAire Series 42 Inch Packaged Terminal Air Conditioner Warranty ZoneAire Series 42 Inch Packaged Terminal Air Conditioner Warranty Guide 7,200 BTU Packaged Terminal Air Conditioner Installation and Operation Manual HEAT PUMPS 7,200 BTU Packaged Terminal Air Conditioner Product Profile