Troubleshooting – Harbor Freight Tools 98733 User Manual

Page 13

SKU 98733

For technical questions, please call 1-800-444-3353.

Page 13

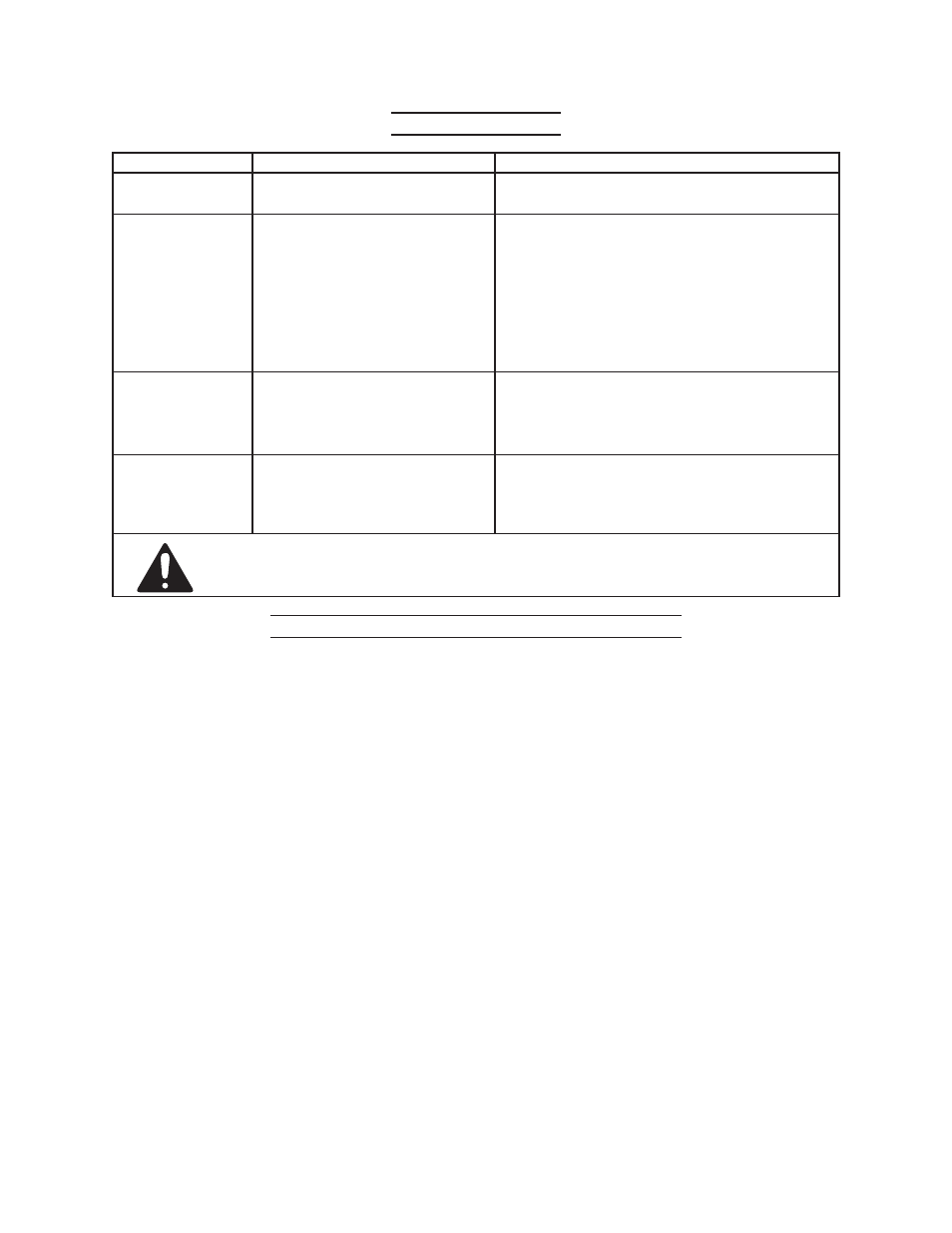

Troubleshooting

Problem

Possible Causes

Likely Solutions

Air leaking in

Cylinder Cap (8A).

1. Loose Screw (6).

2. O-ring (9A) is cracked or worn.

1. Tighten and recheck.

2. Replace O-ring.

Lack of power.

Slow to cycle.

Low power when

shooting and

returning.

1. Tool is too dry.

2. Air pressure too low.

3. Exhaust blocked.

1. Add about 3 drops of pneumatic tool oil into

the Air Plug (83).

2. Check to make sure regulator on air

compressor is set between 70 PSI and 120

PSI. (70 PSI is the minimum where the Nailer

may work. If power is too low, set it between

100-120 PSI.)

3. Clean exhaust channel.

Not shooting

fasteners or

only intermittent

feeding.

1. Damaged Torsion Spring (76).

2. Wrong size of fasteners.

3. Magazine (71) is dirty.

1. Replace Spring.

2. Use 2-3/16” to 3-1/2”, .113”-.131” diameter

Nails.

3. Clean Magazine.

Fastener is

jammed in tool.

1. Feeder Shoe (69) is broken or

worn.

2. Bent fasteners.

1. Replace Feeder Shoe.

2. Remove bent fasteners. Replace with new

Nails.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED

TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF

HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT

OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

REV 09g,09i; 09l